Source : HOBBWINGDate : 20th Jun 2025

In high-voltage and heavy-lift UAV applications, the reliability of the power system is critical. HOBBYWING P50M high-voltage propulsion system is engineered with automotive-grade design, high-spec materials, and multiple redundancy protections to ensure flight safety and system stability. It is widely applicable to demanding operations such as power line inspection, energy monitoring, and emergency response.

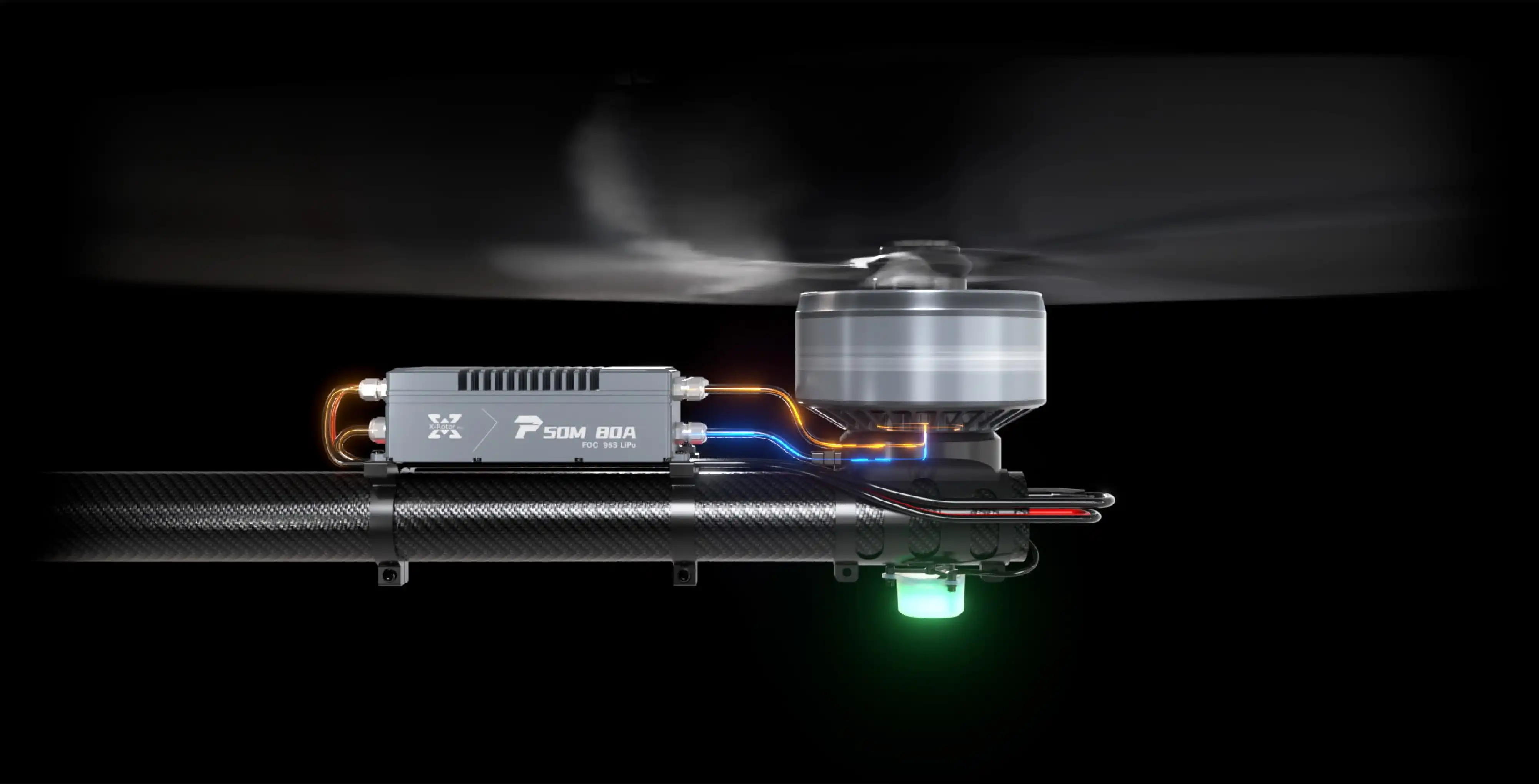

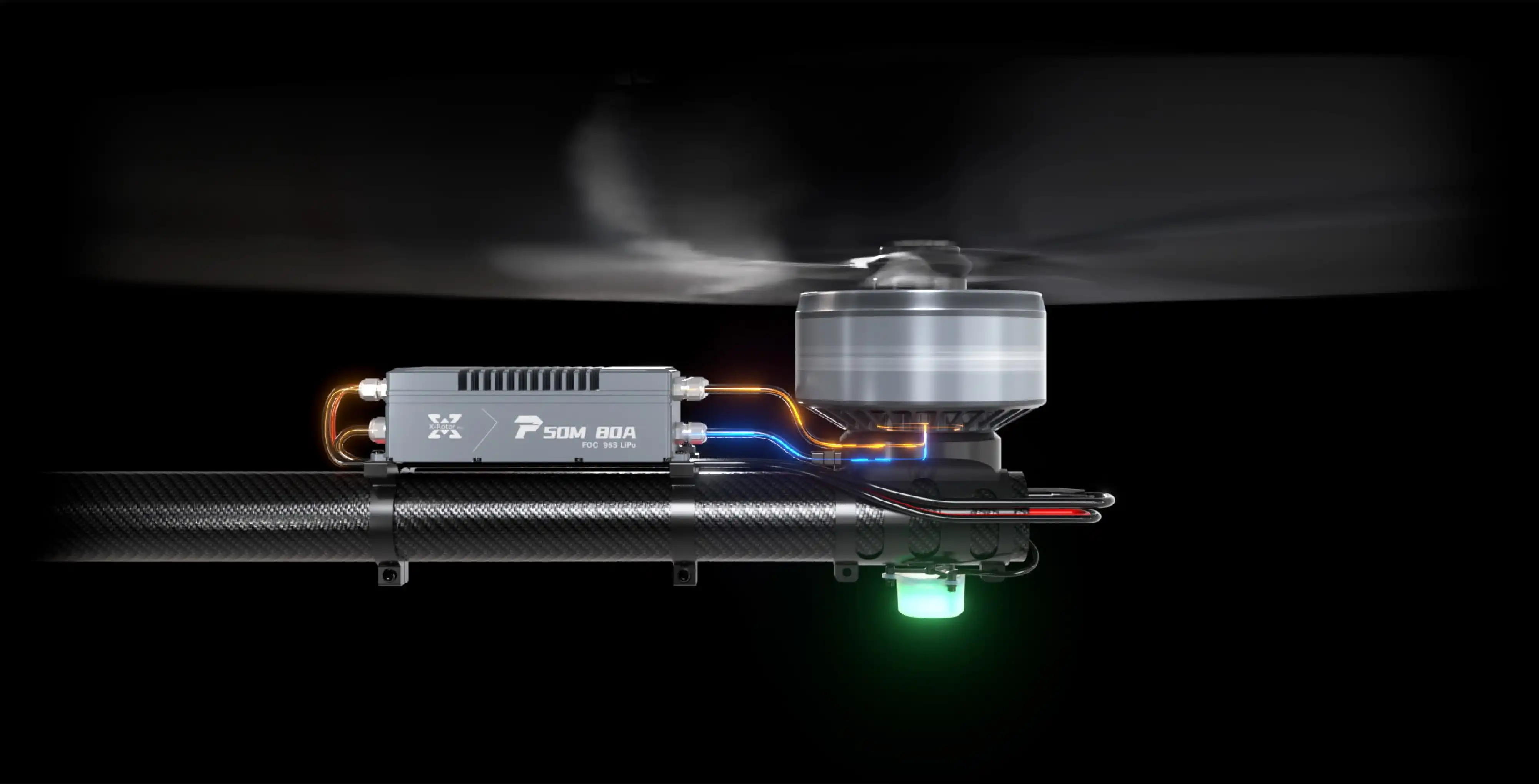

ESC: Built with automotive-grade components and rated IP67, adapted to various harsh environments.

Motor: Adopts high-temperature-resistant materials, knurled shaft, and anti-loosening screw structure, effectively preventing the screws from loosening during flight.

Propeller: Constructed with carbon fiber molding and high-temperature-resistant core material for high strength, high efficiency, and strong environmental adaptability.

Connectors: Both high-voltage and low-voltage signal connectors are made of automotive-grade materials, offering anti-reverse insertion, anti-vibration, avoiding problems such as poor connection, ensuring stable system connections, and extended service life.

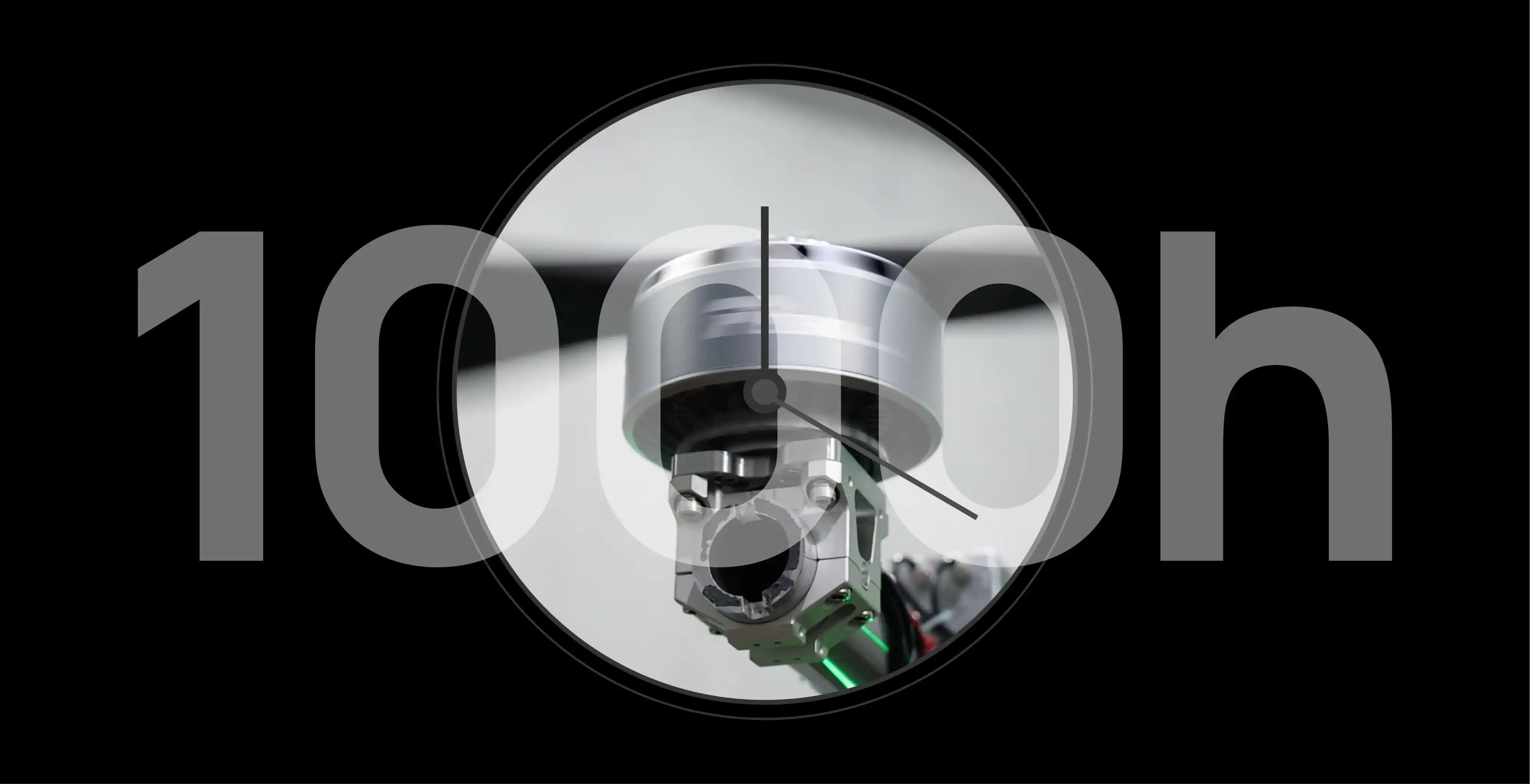

HOBBYWING P50M propulsion system also features 1800V insulation resistance and has passed over 1,000 hours of aging tests, enabling lifetime maintenance-free performance.

P50M is equipped with a dedicated high-voltage power circuit, supporting a maximum input voltage of 450V.

The high-voltage power supply circuit, low-voltage signal circuit and earth (PE) are fully isolated to improve data transmission stability, ensuring stable operation of P50M propulsion system, and enhancing the safety of personnel and equipment during drone operations.

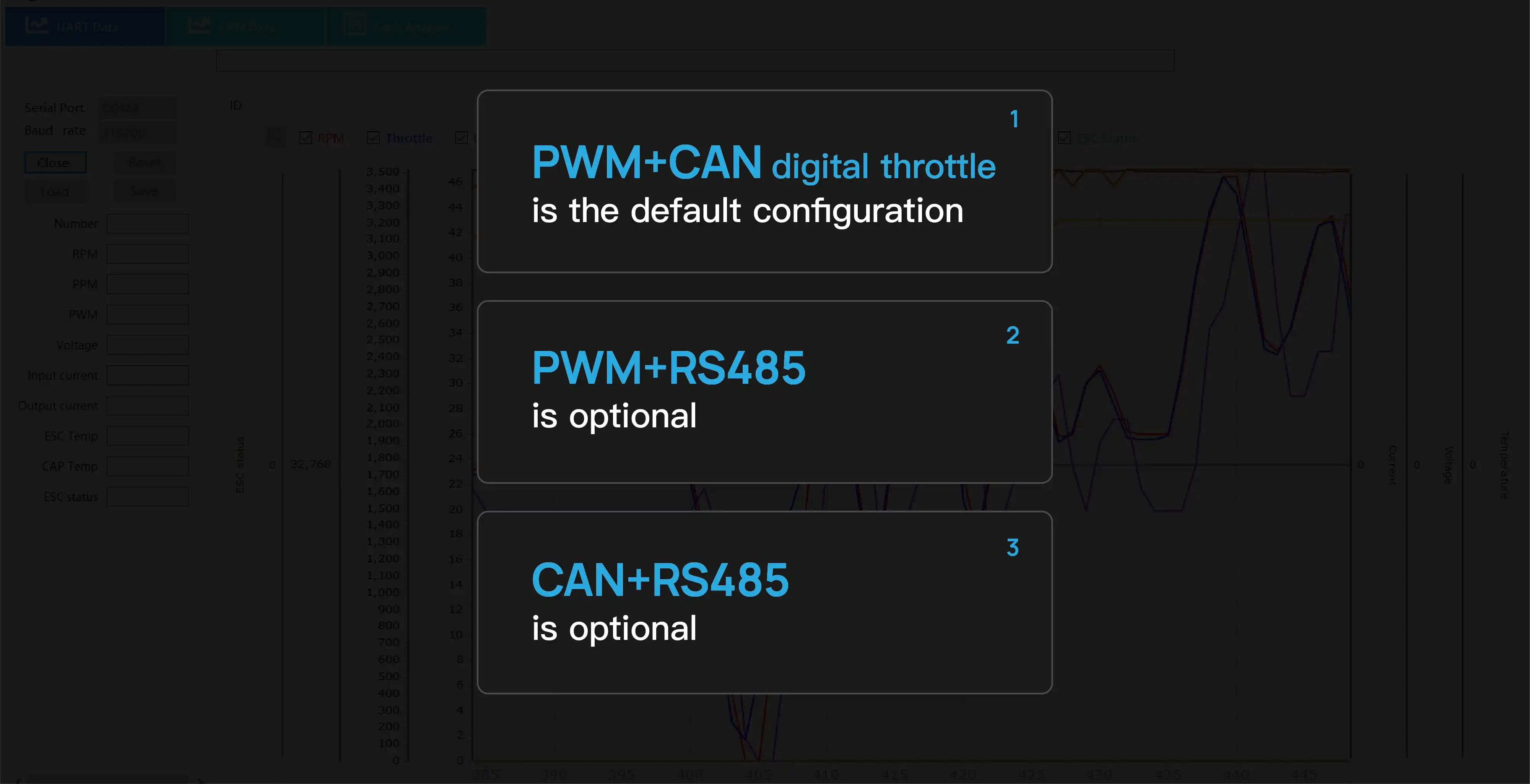

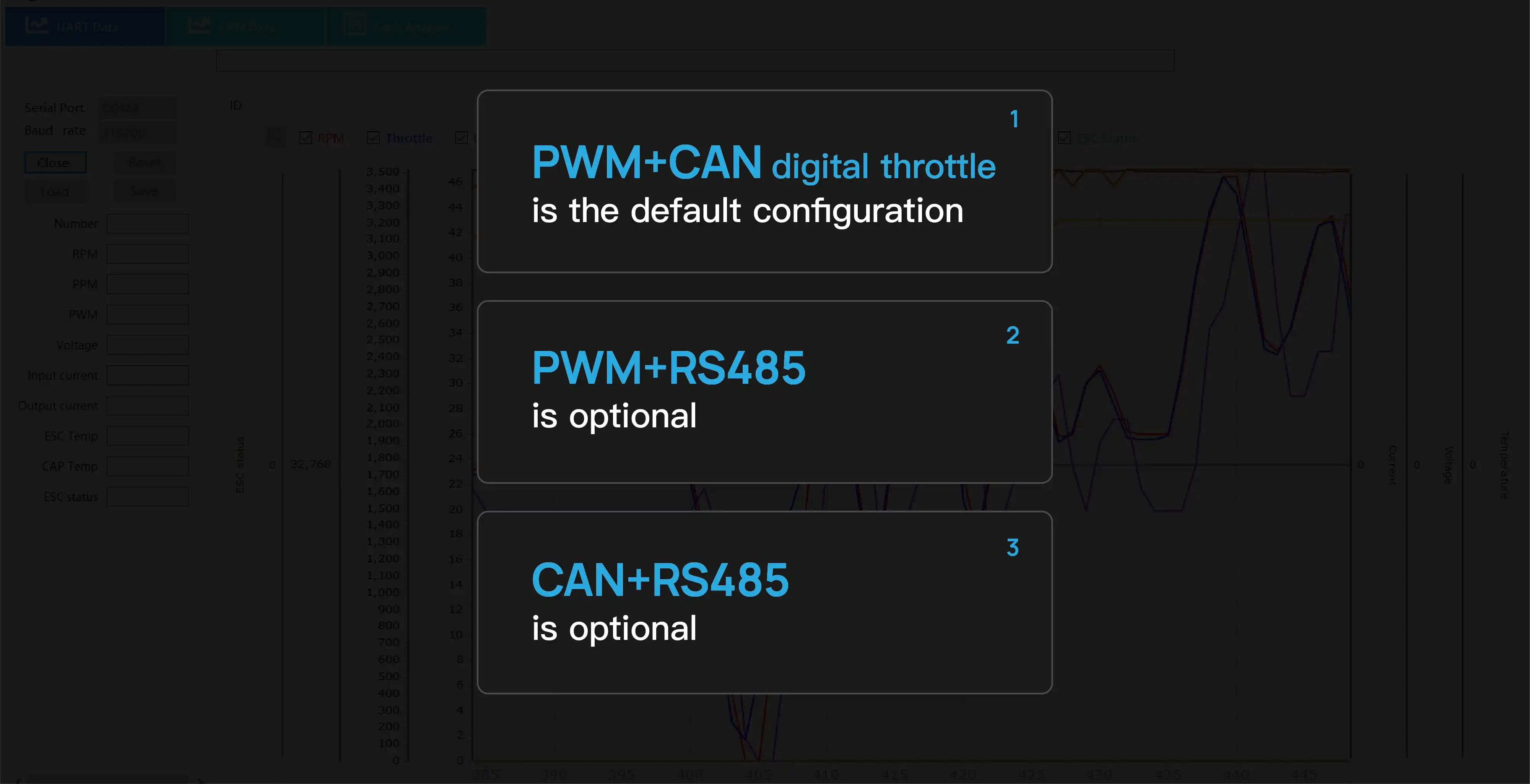

P50M supports dual bus communication protocols: CAN and RS485, and three throttle configurations: default PWM + CAN, optional: PWM + RS485 or CAN + RS485.

In flight missions with electromagnetic interference or long endurance requirements, the drone's anti-interference ability can be improved to ensure flight safety.

P50M is compatible with major flight controller systems including ArduPilot, VK, Byaero, and JIYI, enabling real-time monitoring of key flight parameters (such as RPM, throttle, current, voltage, temperature,etc.) via CAN communication, improving data analysis speed and response efficiency, and further enhancing flight safety.

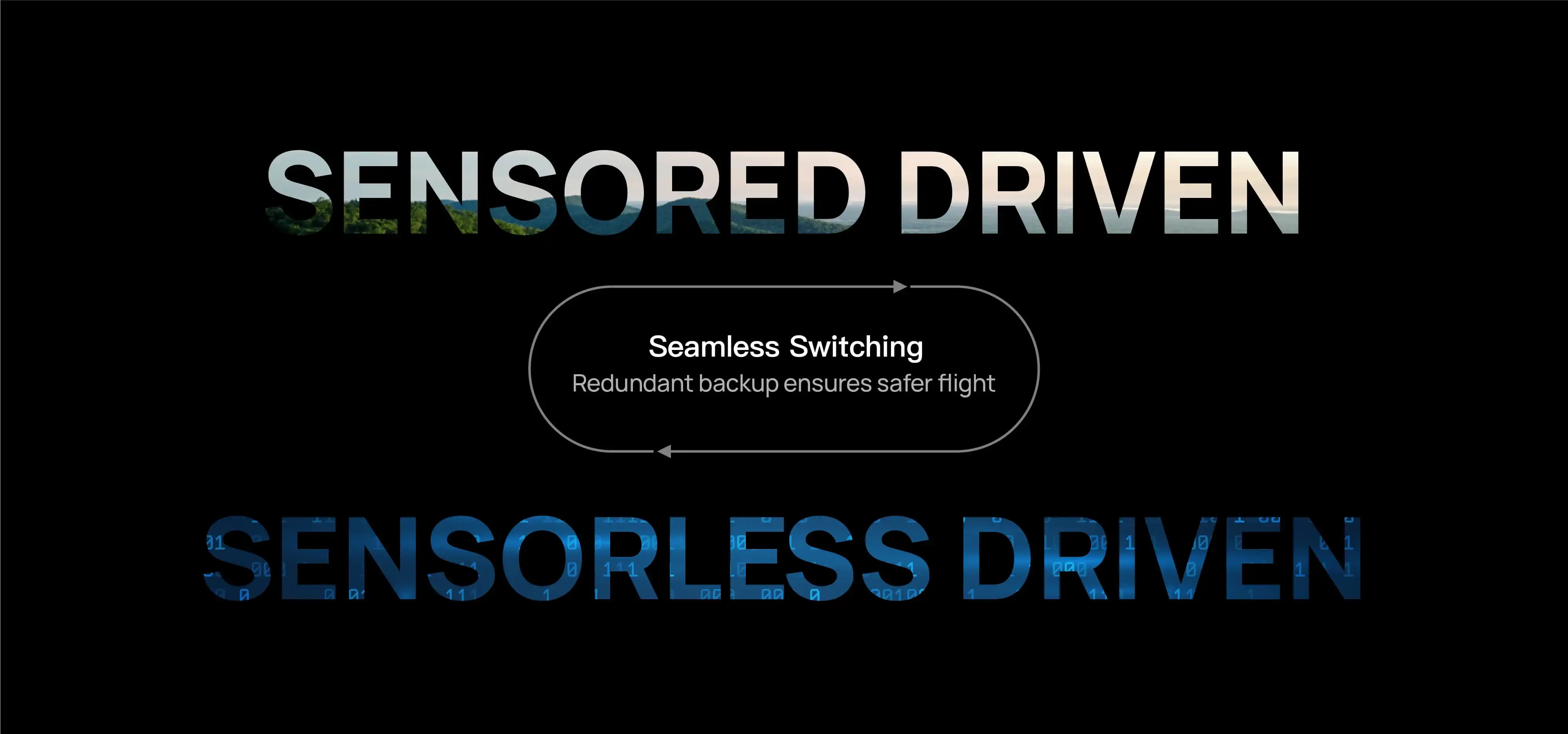

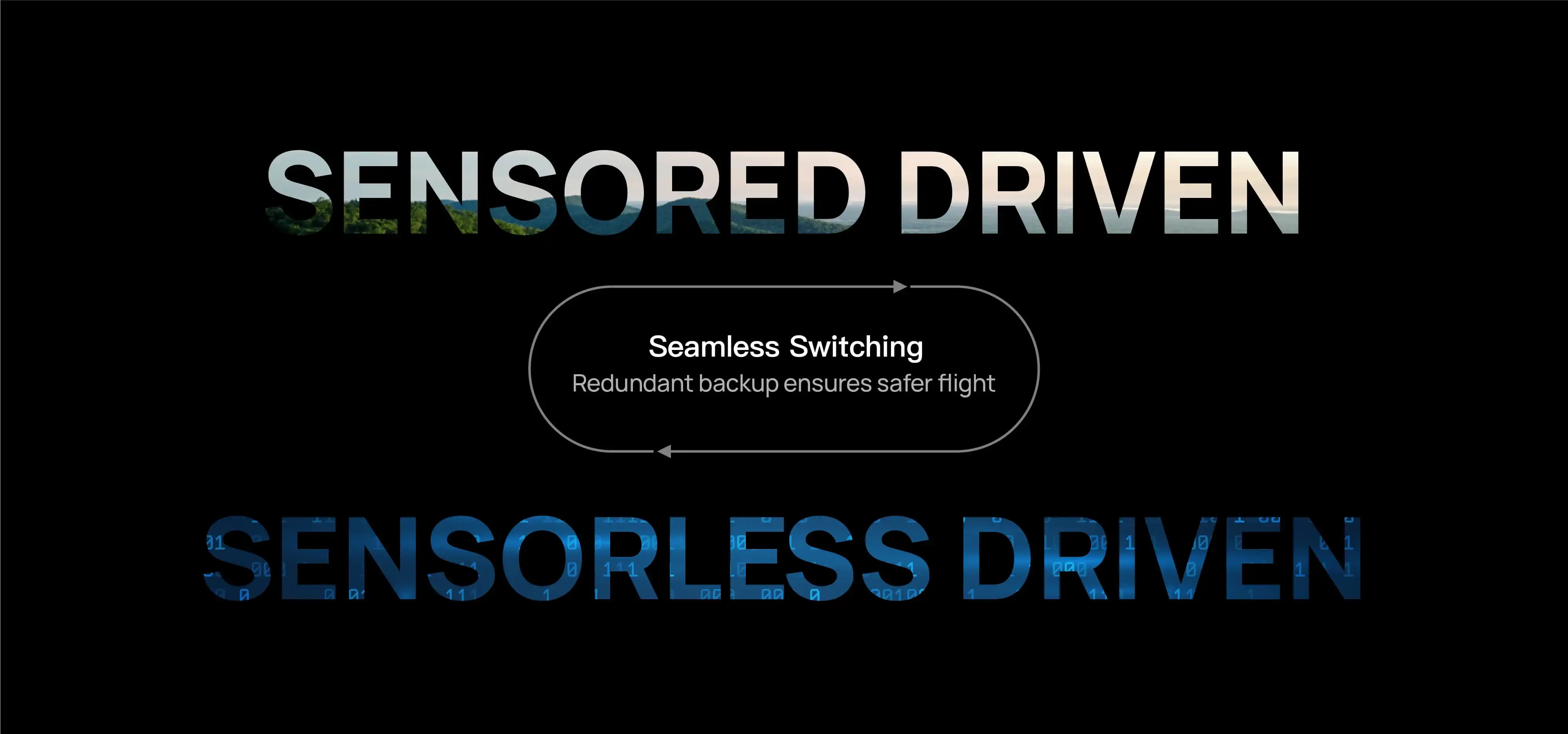

Additionally, P50M features dual channels of sensorless and sensored drive redundancy, allowing seamless switching between drive modes to improve propulsion system stability and reliability.

HOBBYWING P50M propulsion system, with its high-voltage adaptability, fully isolated design, and multiple redundancy, helps UAVs improve operational safety and efficiency. With automotive-grade quality and rigorous testing standards, P50M not only meets the practical demands of complex UAV missions for safety, compatibility and durability, but also reflects HOBBYWING’s deep technical strength in the field of industrial-grade drone propulsion systems.

Source:HOBBWINGDate: 20th Jun 2025

In high-voltage and heavy-lift UAV applications, the reliability of the power system is critical. HOBBYWING P50M high-voltage propulsion system is engineered with automotive-grade design, high-spec materials, and multiple redundancy protections to ensure flight safety and system stability. It is widely applicable to demanding operations such as power line inspection, energy monitoring, and emergency response.

ESC: Built with automotive-grade components and rated IP67, adapted to various harsh environments.

Motor: Adopts high-temperature-resistant materials, knurled shaft, and anti-loosening screw structure, effectively preventing the screws from loosening during flight.

Propeller: Constructed with carbon fiber molding and high-temperature-resistant core material for high strength, high efficiency, and strong environmental adaptability.

Connectors: Both high-voltage and low-voltage signal connectors are made of automotive-grade materials, offering anti-reverse insertion, anti-vibration, avoiding problems such as poor connection, ensuring stable system connections, and extended service life.

HOBBYWING P50M propulsion system also features 1800V insulation resistance and has passed over 1,000 hours of aging tests, enabling lifetime maintenance-free performance.

P50M is equipped with a dedicated high-voltage power circuit, supporting a maximum input voltage of 450V.

The high-voltage power supply circuit, low-voltage signal circuit and earth (PE) are fully isolated to improve data transmission stability, ensuring stable operation of P50M propulsion system, and enhancing the safety of personnel and equipment during drone operations.

P50M supports dual bus communication protocols: CAN and RS485, and three throttle configurations: default PWM + CAN, optional: PWM + RS485 or CAN + RS485.

In flight missions with electromagnetic interference or long endurance requirements, the drone's anti-interference ability can be improved to ensure flight safety.

P50M is compatible with major flight controller systems including ArduPilot, VK, Byaero, and JIYI, enabling real-time monitoring of key flight parameters (such as RPM, throttle, current, voltage, temperature,etc.) via CAN communication, improving data analysis speed and response efficiency, and further enhancing flight safety.

Additionally, P50M features dual channels of sensorless and sensored drive redundancy, allowing seamless switching between drive modes to improve propulsion system stability and reliability.

HOBBYWING P50M propulsion system, with its high-voltage adaptability, fully isolated design, and multiple redundancy, helps UAVs improve operational safety and efficiency. With automotive-grade quality and rigorous testing standards, P50M not only meets the practical demands of complex UAV missions for safety, compatibility and durability, but also reflects HOBBYWING’s deep technical strength in the field of industrial-grade drone propulsion systems.