Source : HOBBYWINGDate : 4th Jan 2026

HOBBYWING C series motors are ideal cruise propulsion for fixed-wing and VTOL UAVs, and a perfect electric replacement solution for gasoline engines.

| Motor | KV | Rated Thrust | Gasoline Engines to Replace |

| C7215 | 200KV | 5.5kg | 30CC |

| C8020 | 180KV/210KV | 7.5kg | 55CC |

| C8025 | 160KV/190KV | 8.5kg | 70CC |

| C8030 | 160KV/190KV | 10kg | 85CC |

C series motors delivers strong thrust to handle rapid load and flight-condition transitions with ease.

| Motor | Recommended Propeller | Max Thrust |

| C7215 | 19/20/21 inch | 16kg |

| C8020 | 25 inch | 22.6kg |

| C8025 | 26 inch | 24.7kg |

| C8030 | 27 inch | 30.4kg |

The rotor bracket features a rectangular exhaust outlet that reduces airflow resistance and turbulence, improving heat exhaust efficiency and increasing cooling performance by 20%. The C8020, C8025, and C8030 fixed wing motors exhibit significantly lower winding temperature rise than comparable motors, ensuring stable operation under long-duration, high-load flight conditions.

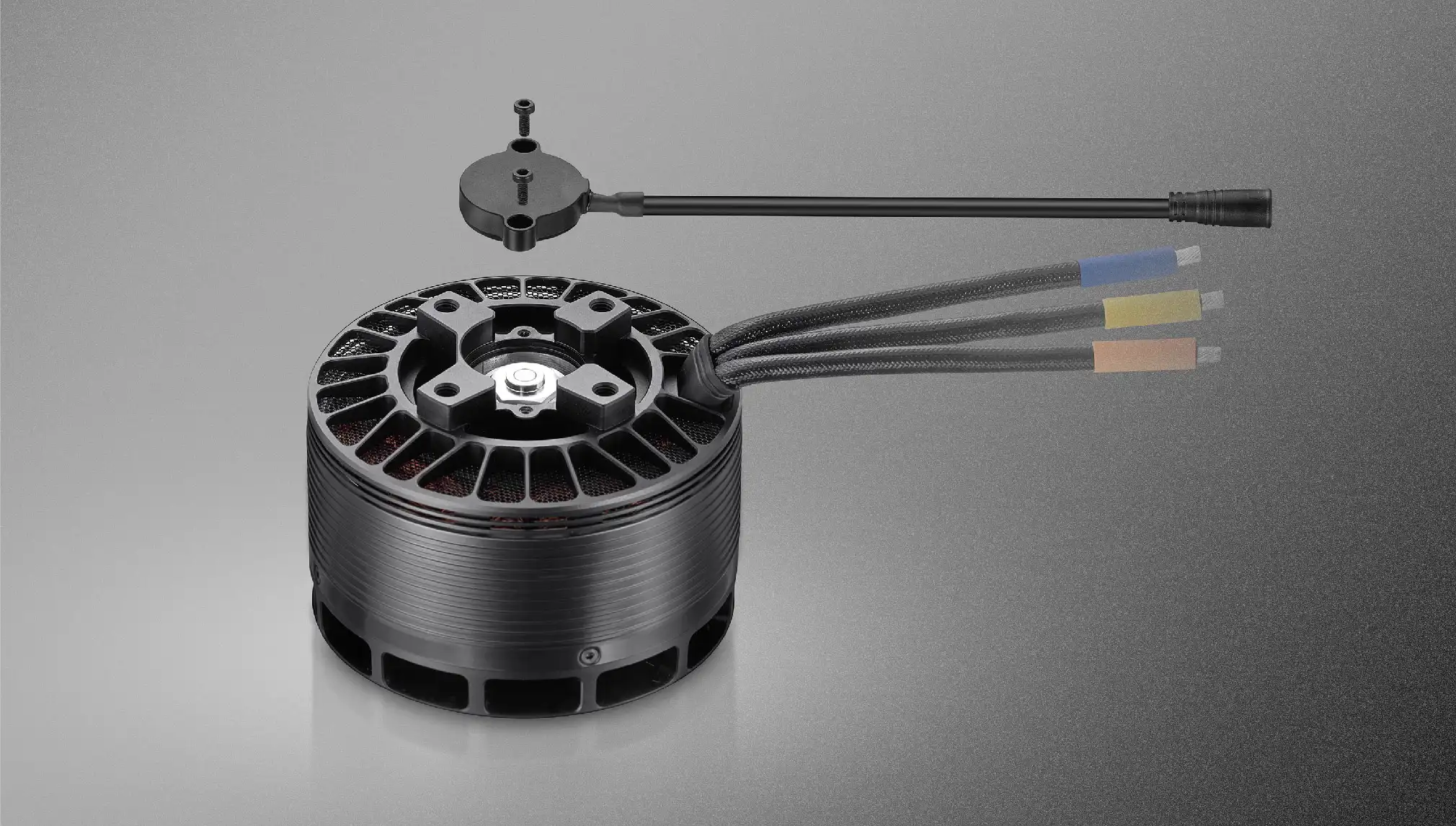

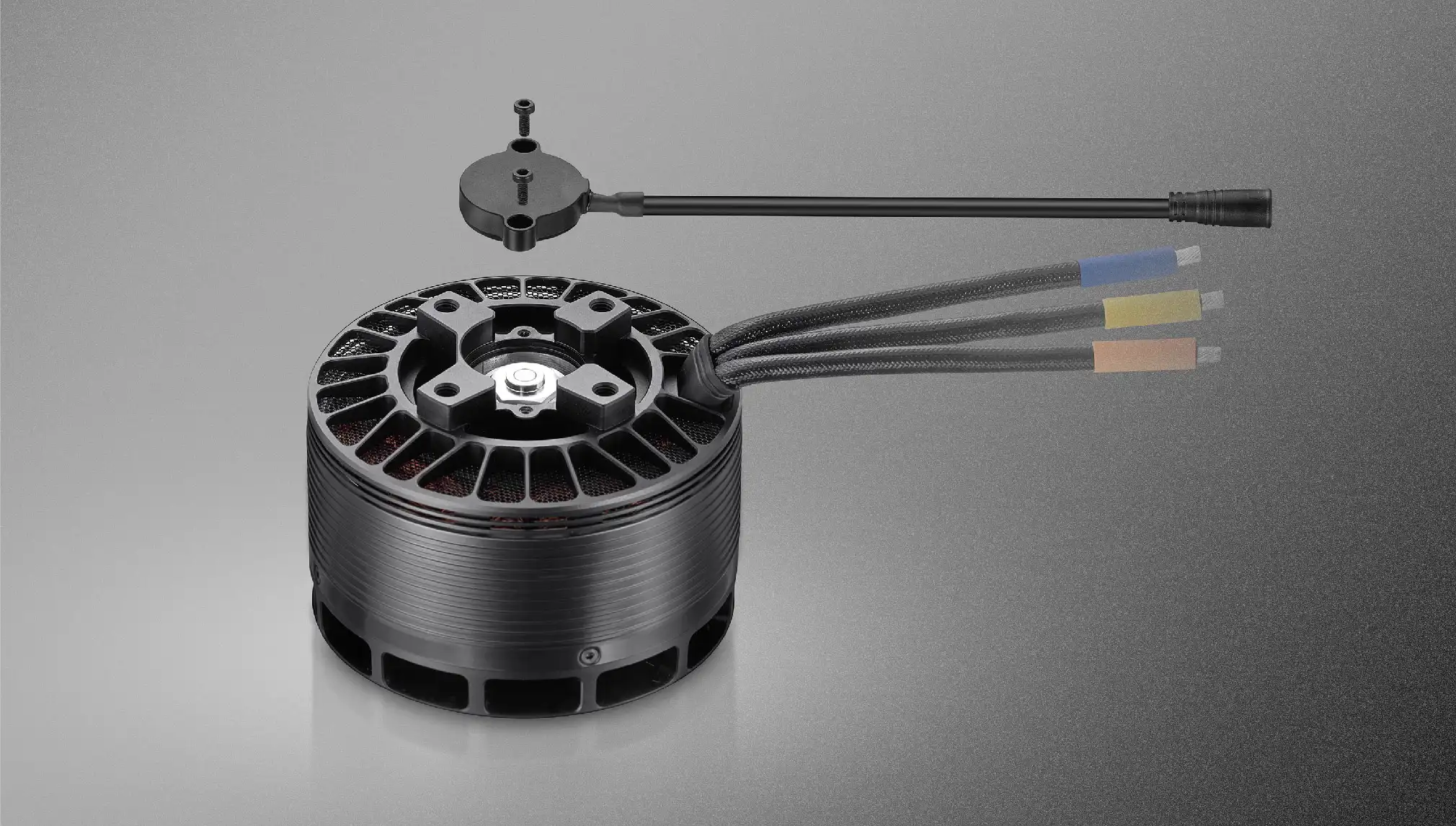

The rotor bracket incorporates a boss clearance design to prevent interference with propeller roots, supporting both standard and folding propellers. A detachable propeller adapter with anti-slip and interlocking design enables quick switching between propeller mounting options, meeting diverse mission requirements.

C series UAV motors also have an IPC feature. When paired with a prop-lock ESC, the propeller stop position can be customized to reduce ground impact risk and enhance operational safety.

The detachable propeller adapter uses a dual-nut, dual-direction locking design to provide anti-slip and self-locking protection, preventing propeller detachment due to nut loosening. Patent Application No.: 202311210278.7

The shaft-to-bracket interface adopts an innovative knurled structure, combined with side set-screw locking. The rotor shaft end is secured with copper washers, circlips, and screws. Multiple anti-loosening measures ensure secure and reliable motor operation.

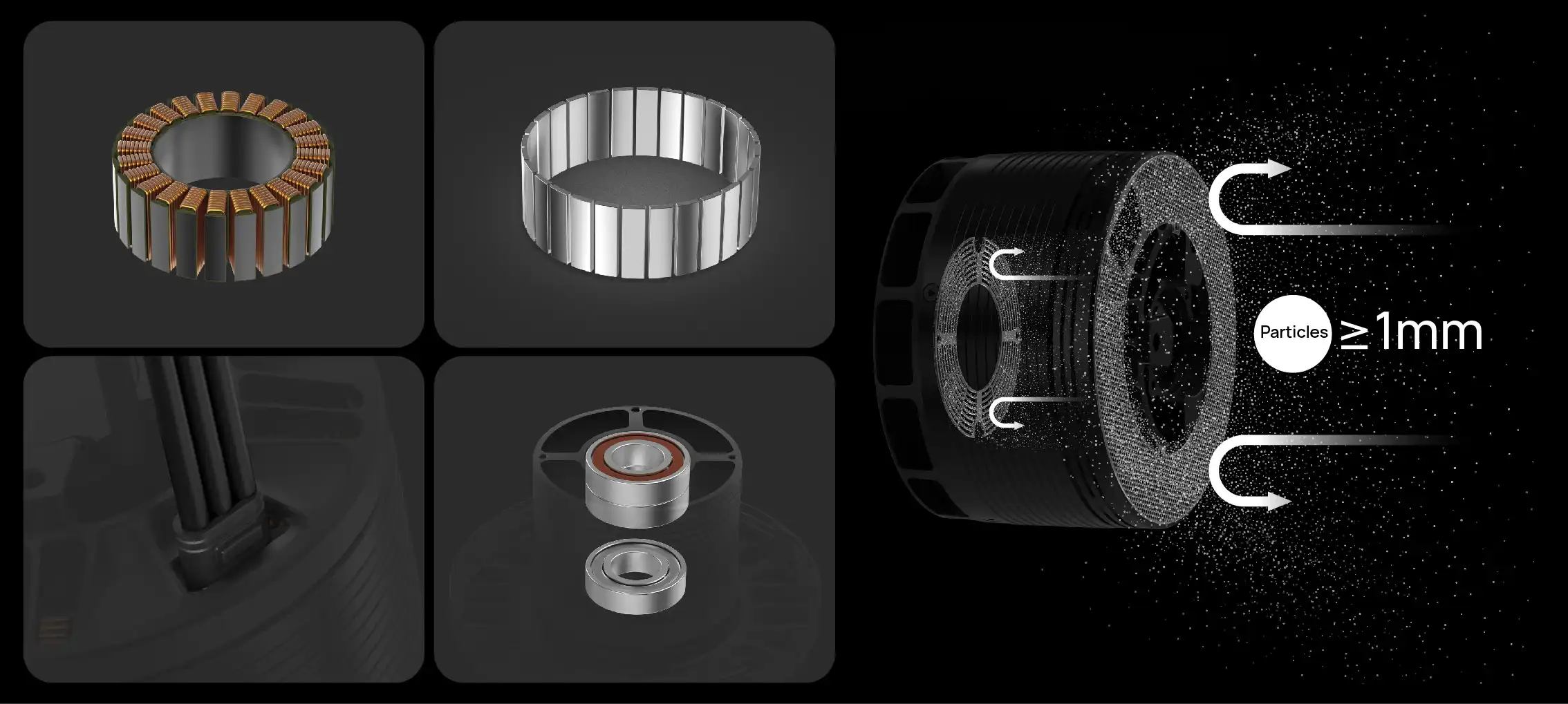

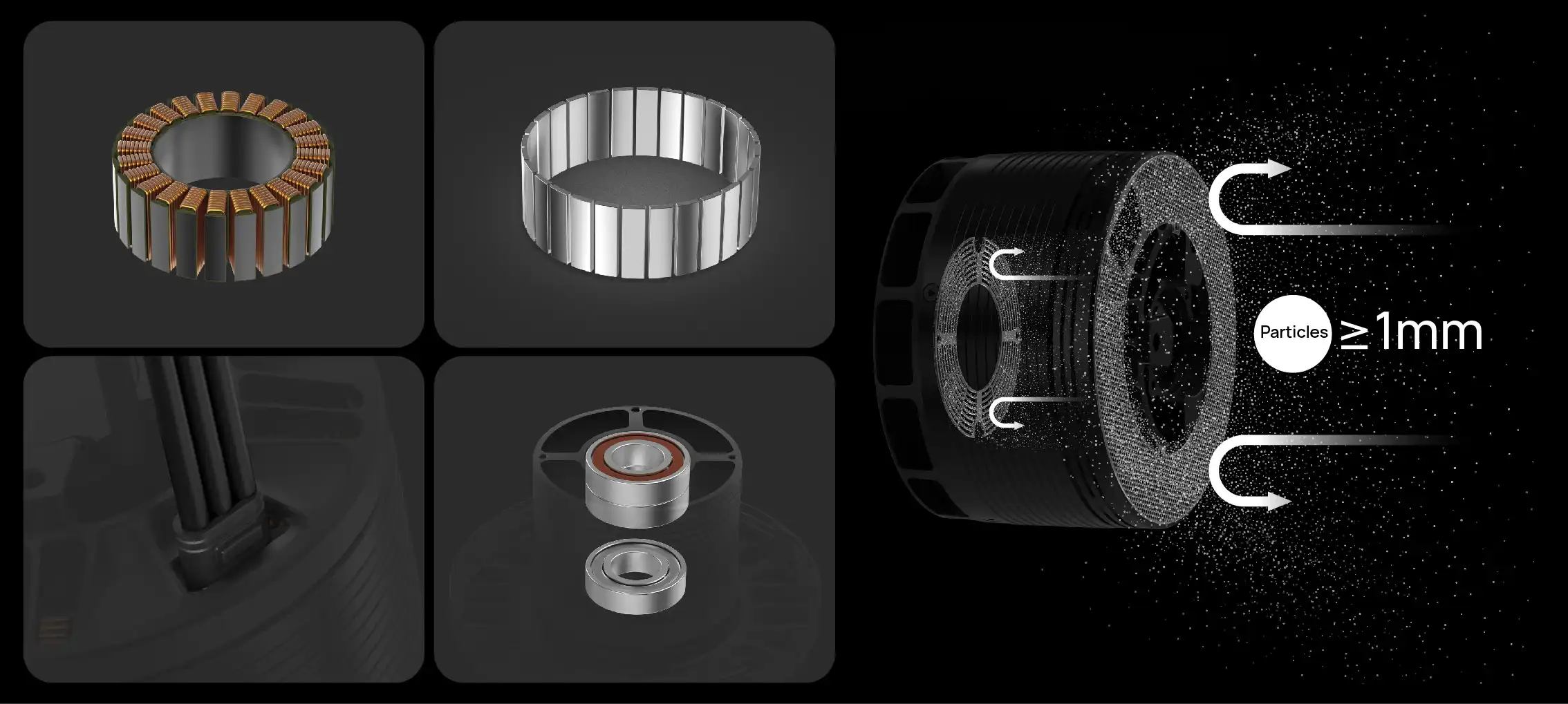

The motors are designed with industry-leading 0.2mm low-loss silicon steel cores, high-grade 240°C temperature-resistant enameled wires, and high-grade strong magnetic arc-shaped magnets.

Custom silicone rubber cable sleeves on three-phase wires provide excellent insulation protection with an aesthetic appearance.

The bottom of the motor is designed with upper and lower steel mesh structure, effectively preventing particles ≥1mm in diameter, allowing the motor to adapt to harsh flight environments, such as dust and rain.

Excellent dynamic balance enhances impact resistance, durability, and overall flight safety.

Optimized to match drive parameters precisely, delivering faster throttle response and smoother power output.

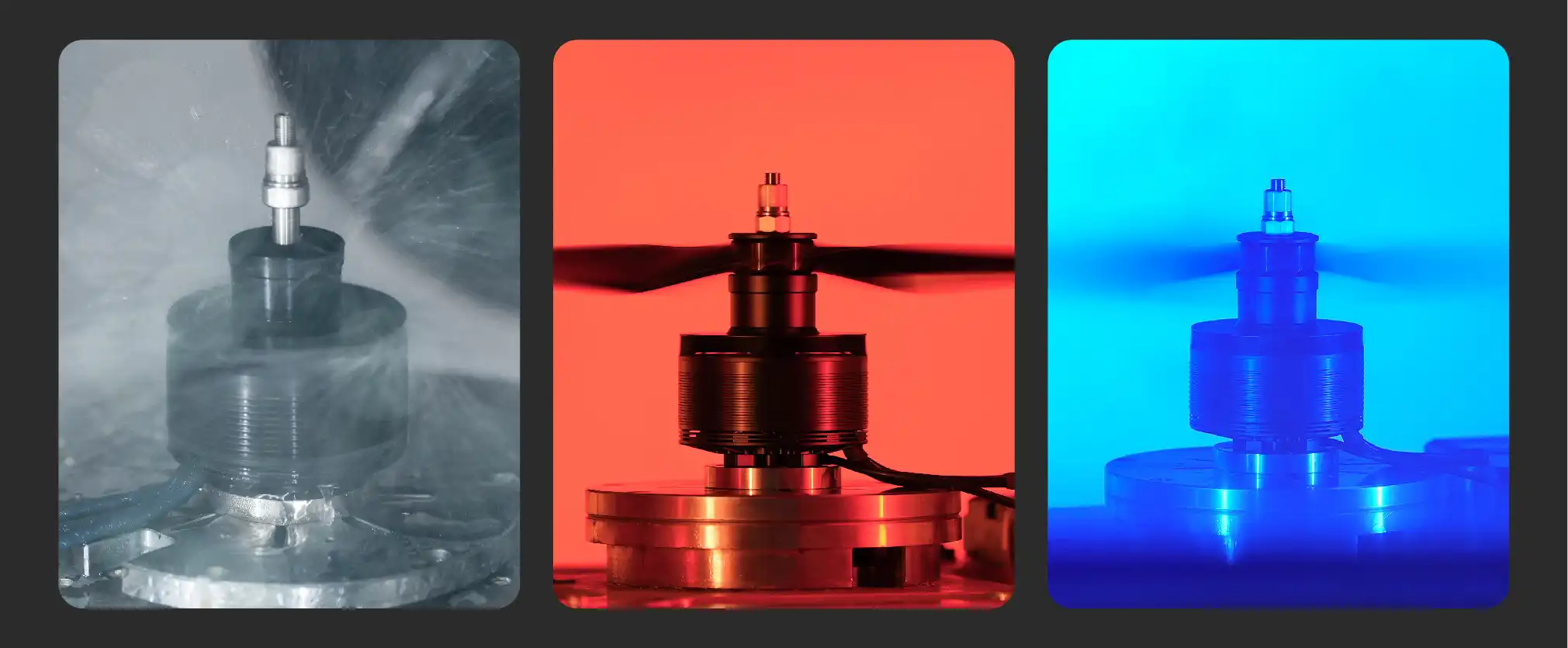

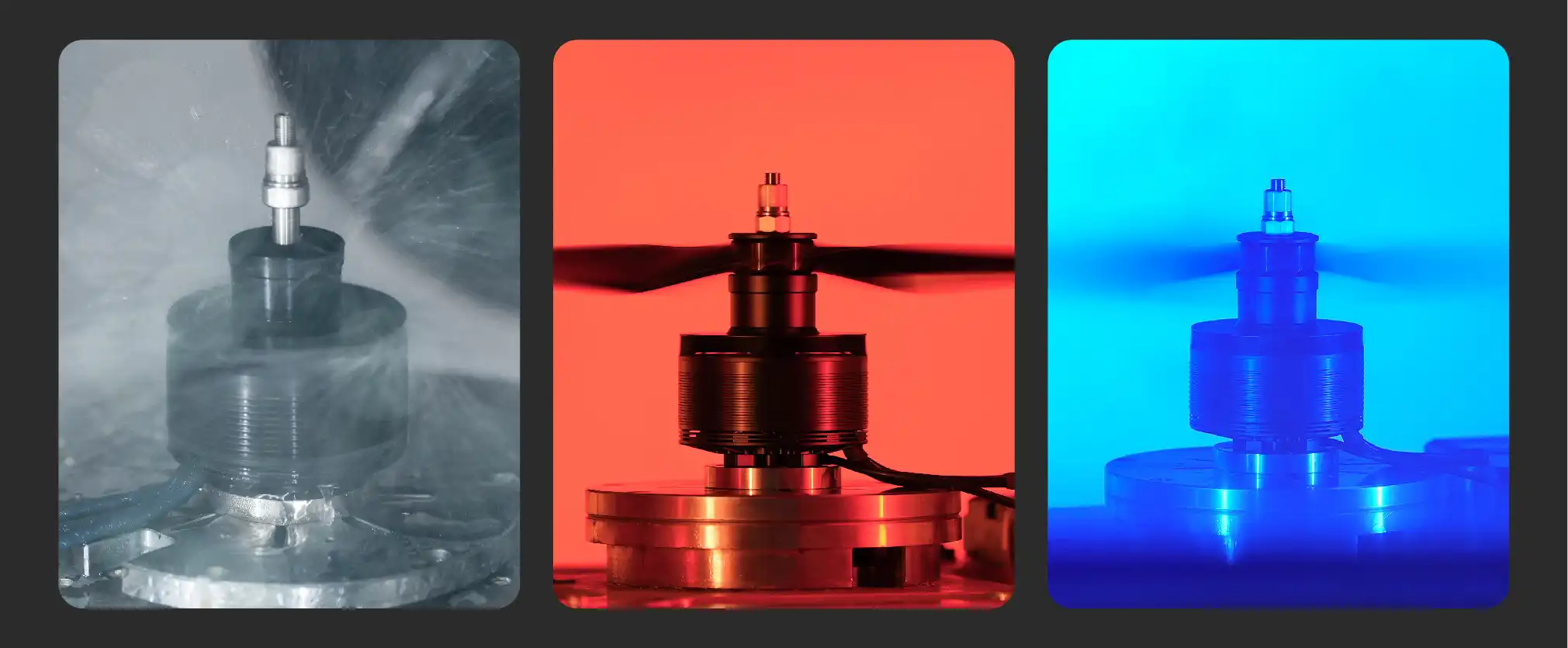

Tested to stringent industry standards, including drive compatibility, water proof test, salt spray test, mechanical stress test, temperature/humidity combined vibration test, and 1000 hours of laboratory fatigue life test, ensuring sustained stable performance in challenging environments.

| Motor | Recommended Propeller | Recommended ESC | Battery | Takeoff weight of Single motor |

| C7215 | 19/20/21 inch | H130A 14S BLDC IPC | 12S LiPo | 25~30kg |

| C8020 | 22/23/24/25 inch | H200A 14S BLDC IPC | 12S LiPo | 35~40kg |

| C8025 | 23/24/25/26 inch | H200A 14S BLDC IPC | 12S LiPo | 40~45kg |

| C8030 | 24/25/26/27 inch | H200A 14S BLDC IPC | 12S LiPo | 45~55kg |

Source:HOBBYWINGDate: 4th Jan 2026

HOBBYWING C series motors are ideal cruise propulsion for fixed-wing and VTOL UAVs, and a perfect electric replacement solution for gasoline engines.

| Motor | KV | Rated Thrust | Gasoline Engines to Replace |

| C7215 | 200KV | 5.5kg | 30CC |

| C8020 | 180KV/210KV | 7.5kg | 55CC |

| C8025 | 160KV/190KV | 8.5kg | 70CC |

| C8030 | 160KV/190KV | 10kg | 85CC |

C series motors delivers strong thrust to handle rapid load and flight-condition transitions with ease.

| Motor | Recommended Propeller | Max Thrust |

| C7215 | 19/20/21 inch | 16kg |

| C8020 | 25 inch | 22.6kg |

| C8025 | 26 inch | 24.7kg |

| C8030 | 27 inch | 30.4kg |

The rotor bracket features a rectangular exhaust outlet that reduces airflow resistance and turbulence, improving heat exhaust efficiency and increasing cooling performance by 20%. The C8020, C8025, and C8030 fixed wing motors exhibit significantly lower winding temperature rise than comparable motors, ensuring stable operation under long-duration, high-load flight conditions.

The rotor bracket incorporates a boss clearance design to prevent interference with propeller roots, supporting both standard and folding propellers. A detachable propeller adapter with anti-slip and interlocking design enables quick switching between propeller mounting options, meeting diverse mission requirements.

C series UAV motors also have an IPC feature. When paired with a prop-lock ESC, the propeller stop position can be customized to reduce ground impact risk and enhance operational safety.

The detachable propeller adapter uses a dual-nut, dual-direction locking design to provide anti-slip and self-locking protection, preventing propeller detachment due to nut loosening. Patent Application No.: 202311210278.7

The shaft-to-bracket interface adopts an innovative knurled structure, combined with side set-screw locking. The rotor shaft end is secured with copper washers, circlips, and screws. Multiple anti-loosening measures ensure secure and reliable motor operation.

The motors are designed with industry-leading 0.2mm low-loss silicon steel cores, high-grade 240°C temperature-resistant enameled wires, and high-grade strong magnetic arc-shaped magnets.

Custom silicone rubber cable sleeves on three-phase wires provide excellent insulation protection with an aesthetic appearance.

The bottom of the motor is designed with upper and lower steel mesh structure, effectively preventing particles ≥1mm in diameter, allowing the motor to adapt to harsh flight environments, such as dust and rain.

Excellent dynamic balance enhances impact resistance, durability, and overall flight safety.

Optimized to match drive parameters precisely, delivering faster throttle response and smoother power output.

Tested to stringent industry standards, including drive compatibility, water proof test, salt spray test, mechanical stress test, temperature/humidity combined vibration test, and 1000 hours of laboratory fatigue life test, ensuring sustained stable performance in challenging environments.

| Motor | Recommended Propeller | Recommended ESC | Battery | Takeoff weight of Single motor |

| C7215 | 19/20/21 inch | H130A 14S BLDC IPC | 12S LiPo | 25~30kg |

| C8020 | 22/23/24/25 inch | H200A 14S BLDC IPC | 12S LiPo | 35~40kg |

| C8025 | 23/24/25/26 inch | H200A 14S BLDC IPC | 12S LiPo | 40~45kg |

| C8030 | 24/25/26/27 inch | H200A 14S BLDC IPC | 12S LiPo | 45~55kg |