Source : HOBBYWINGDate : 8th Sep 2025

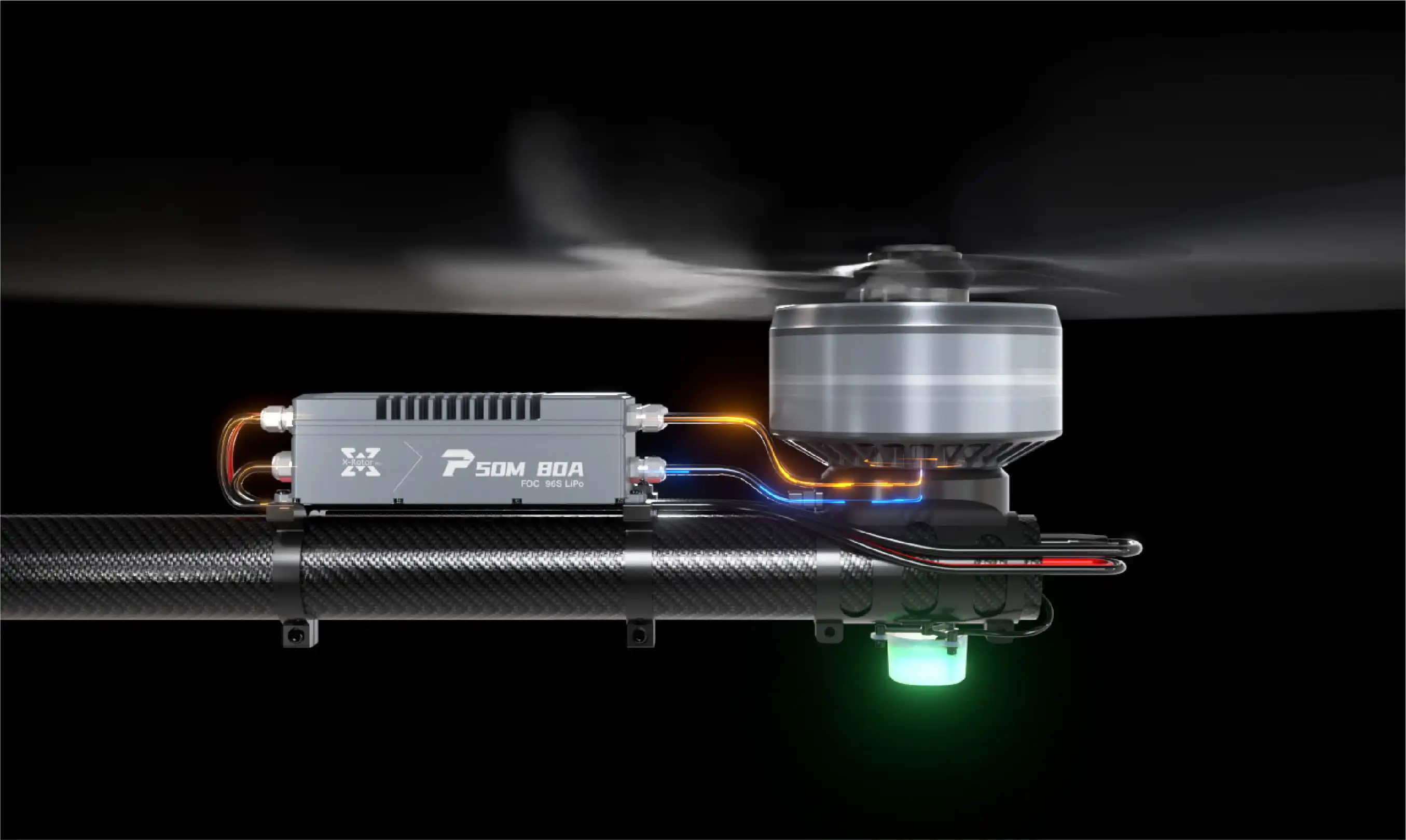

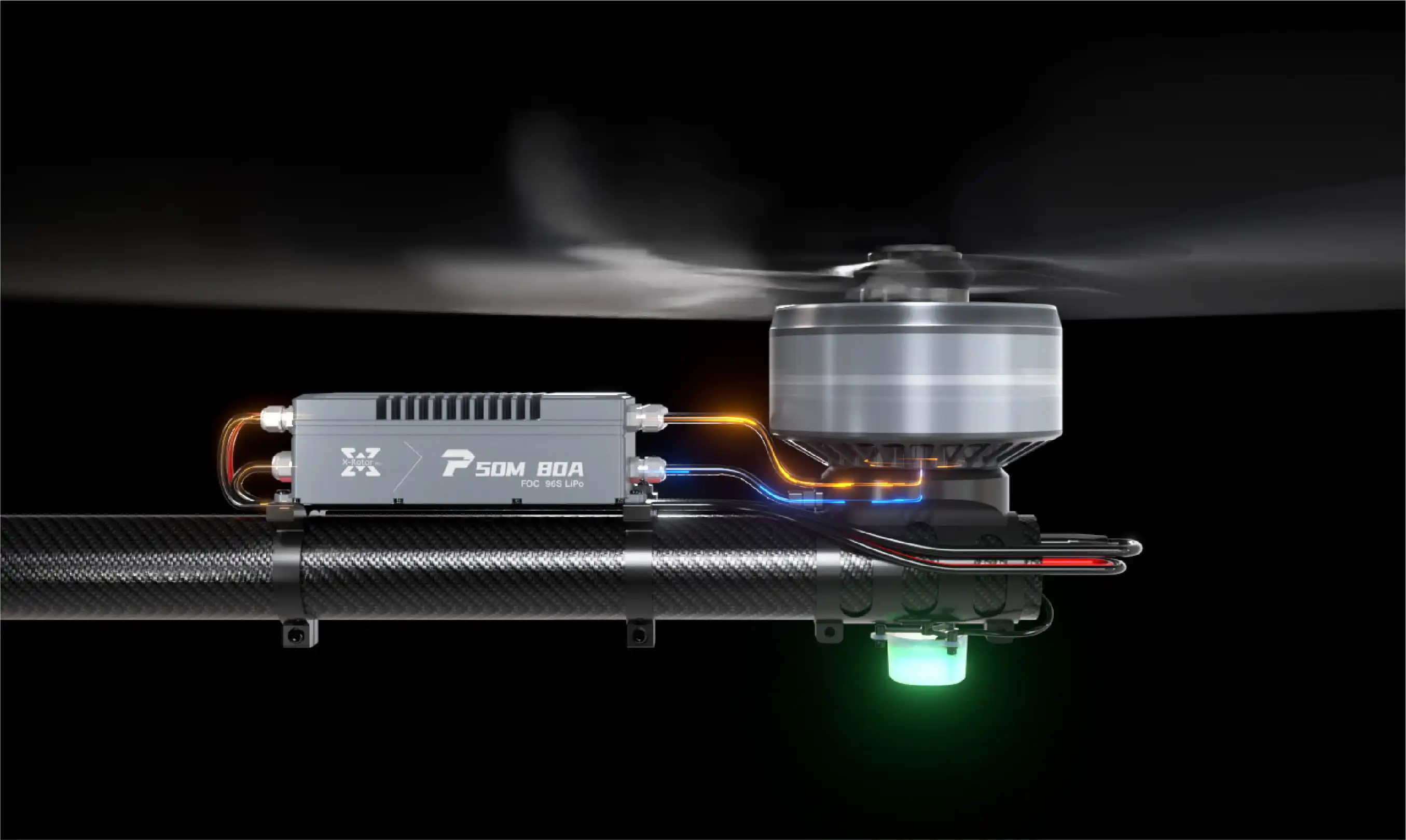

Heavy-duty cargo drones are increasingly deploying 400–800 V high-voltage propulsion systems to reduce overall weight, lower current, and enhance reliability. When using HOBBYWING P series high-voltage drone propulsion systems—including P50M, P65M, and P65V—drone operators may find the following points useful:

The ESC does not include an internal high-voltage pre-charge function. An external pre-charge circuit is required when powering on. Never connect the high-voltage source directly, as this would create an immediate short circuit with extremely high current, causing electrical arcing. Using a pre-charge circuit reduces inrush current and protects the electronic components.

To minimize electromagnetic interference (EMI), the motor and ESC metal housings should be properly grounded. Connect the two interfaces using grounding wires, ensuring the ESC grounding point is free of protective coatings and that the wires are installed without twists or external force.

The motor housing should also be connected to the drone's metal frame to form a complete grounding loop, allowing safe charge dissipation and preventing leakage risks.

ESC communication (CAN/RS485/PWM) should be isolated from the flight controller. The flight controller should be powered by an independent battery or via an isolated DC-DC converter. Common isolation methods include wiring isolation, power isolation, and signal isolation.

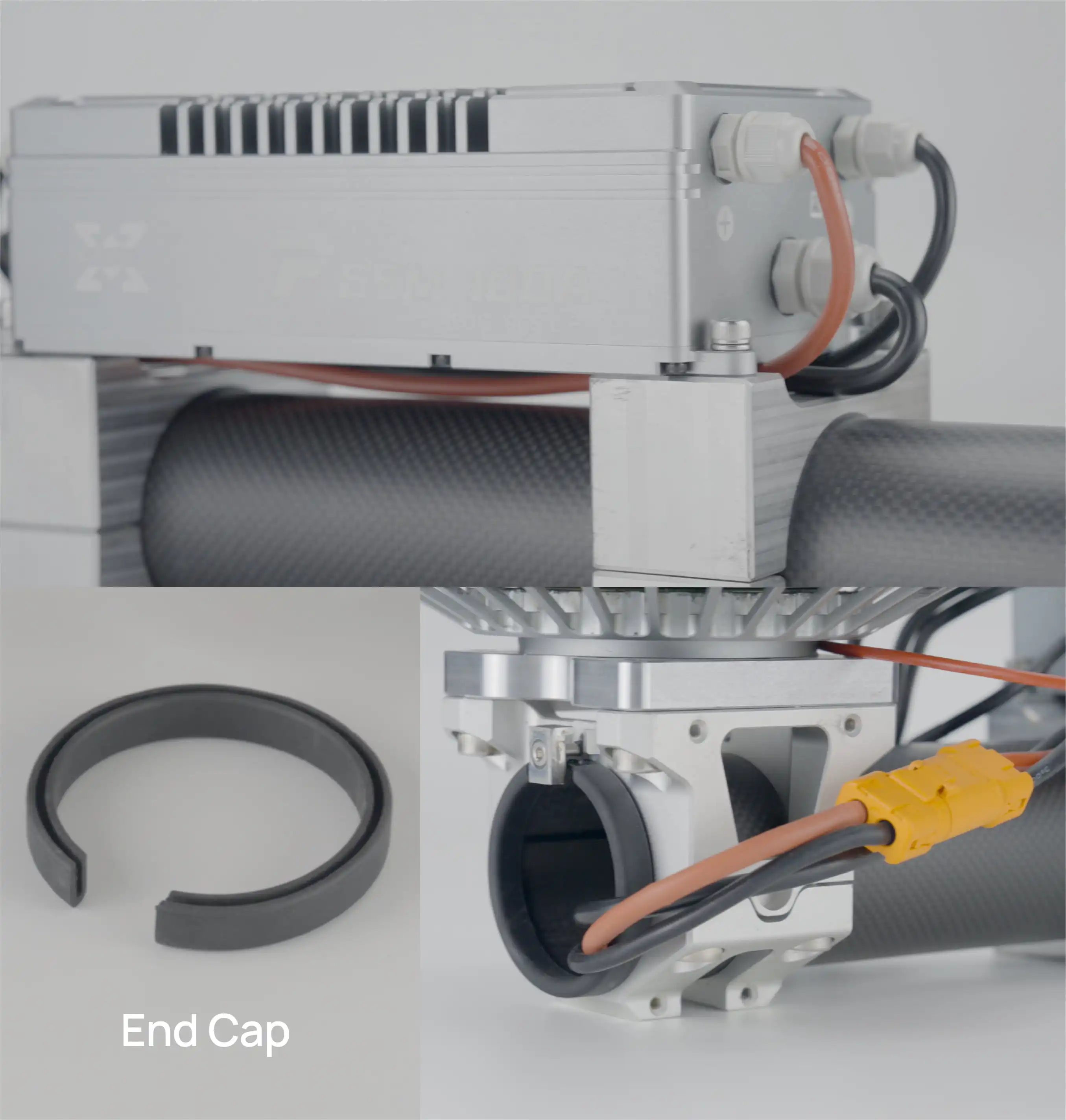

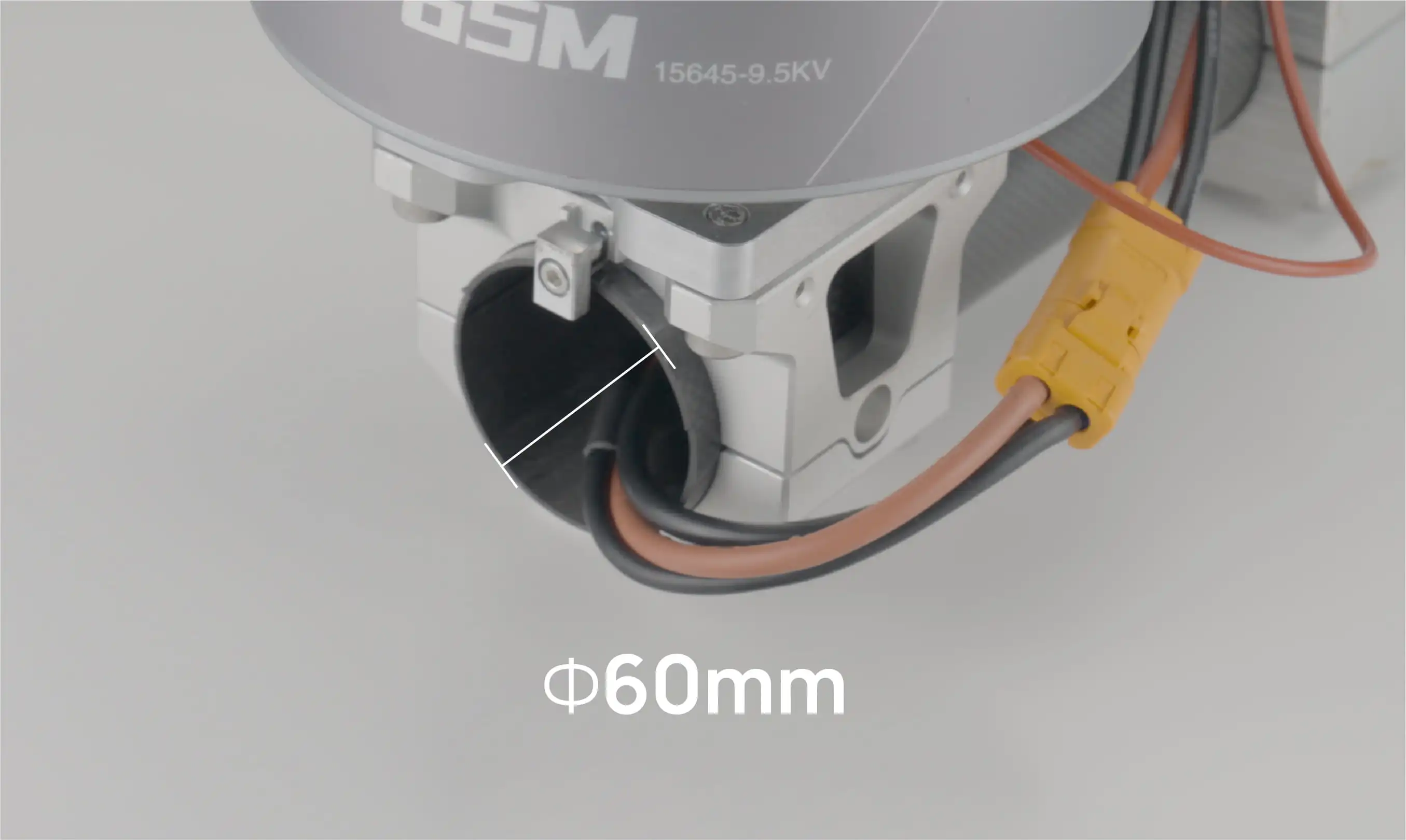

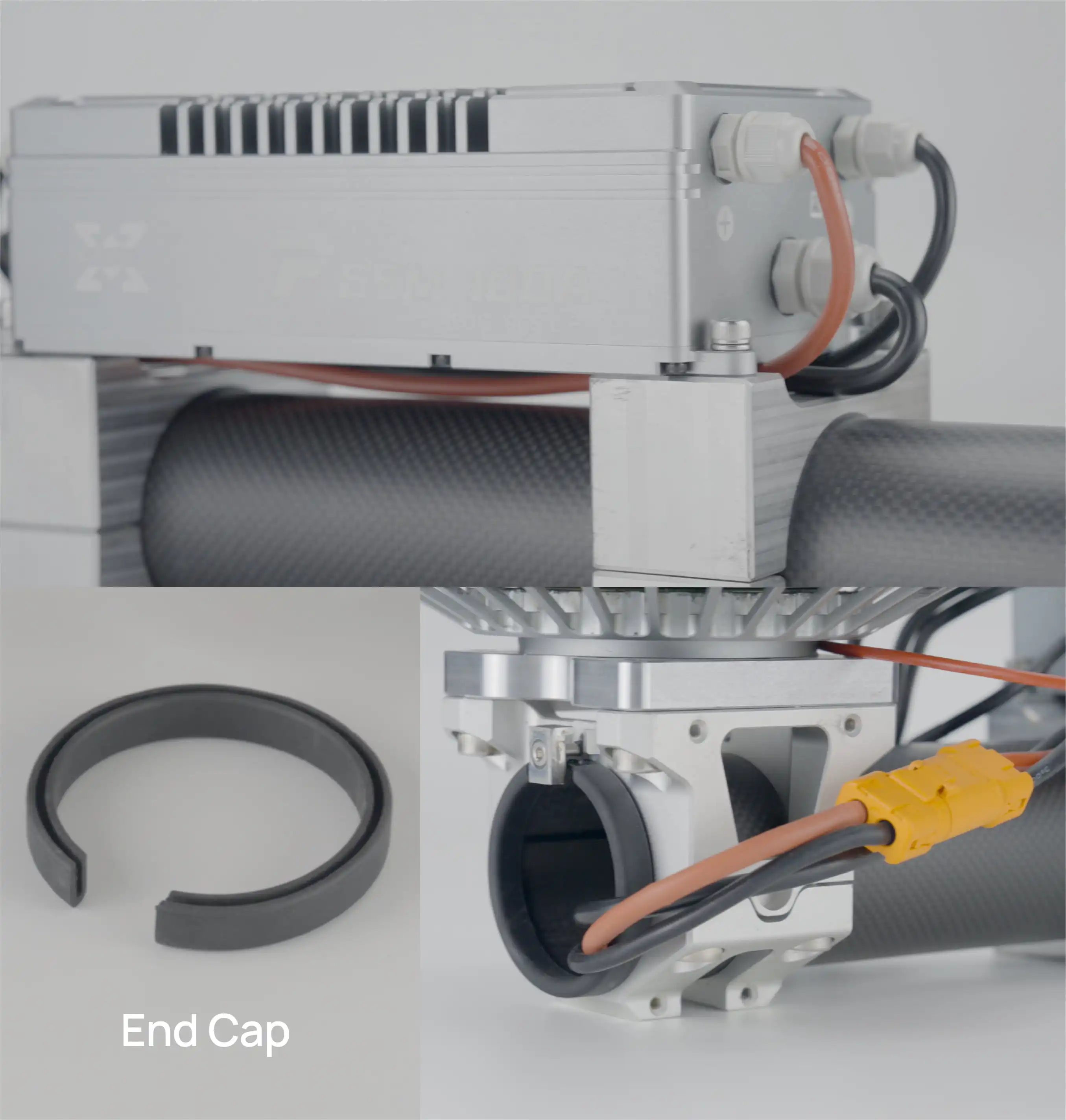

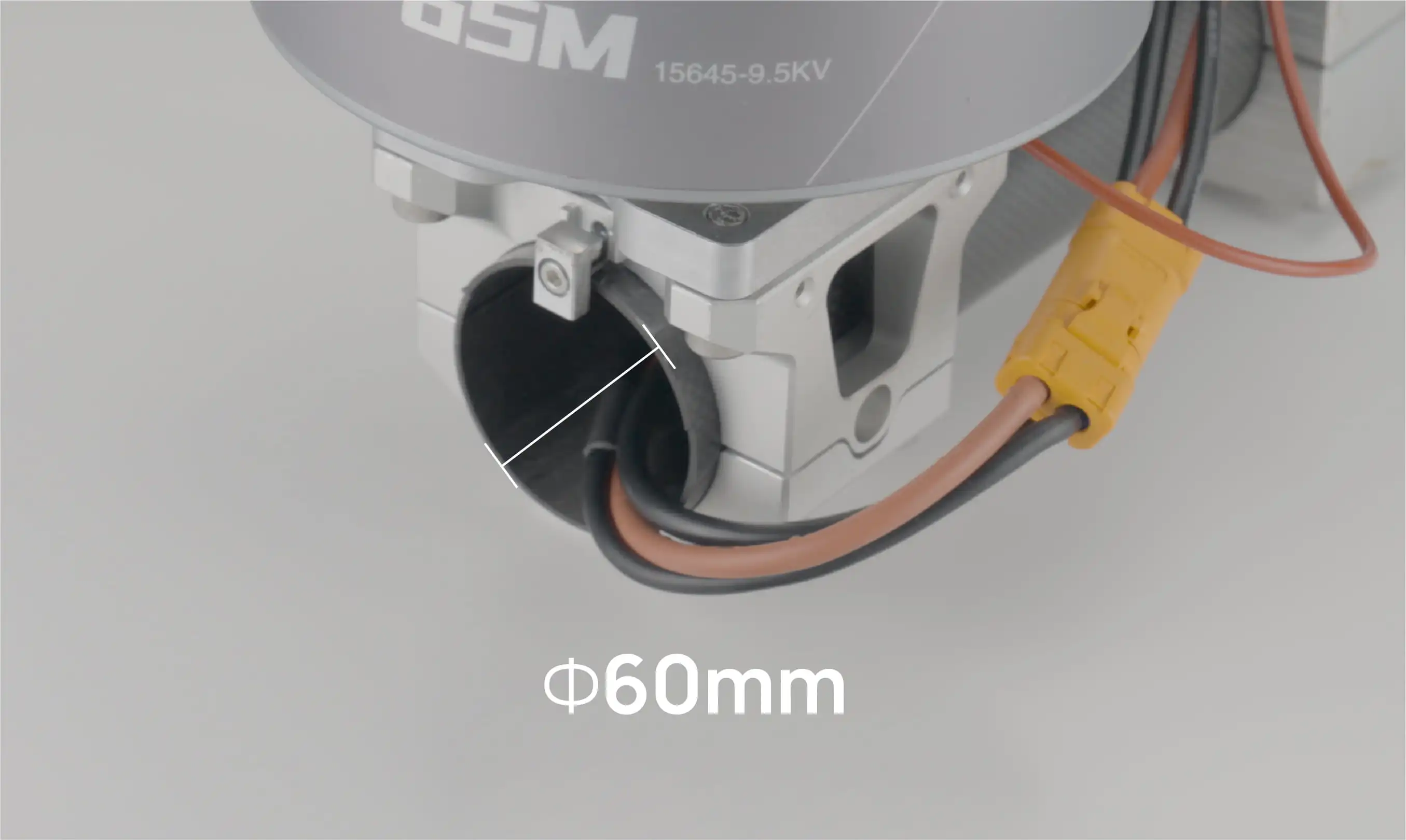

The frame of UAV drone must support its payload while remaining lightweight. For standard flat quadcopter drones, use carbon tubes ≥60 mm diameter with 2.5–3.0 mm wall thickness. Longer arms or coaxial drone setups require larger tube specifications.

Route ESC power and signal wires back through the carbon tube outlet to avoid drilling holes that weaken the arm. Carbon edges can abrade wires during flight. It is recommended to use protective grommets or sleeves to prevent short circuits.

By following the above safety and integration practices, UAV operators can fully leverage the efficiency, reliability, and performance advantages of HOBBYWING P-Series high-voltage propulsion systems in heavy-lift logistics applications.

Source:HOBBYWINGDate: 8th Sep 2025

Heavy-duty cargo drones are increasingly deploying 400–800 V high-voltage propulsion systems to reduce overall weight, lower current, and enhance reliability. When using HOBBYWING P series high-voltage drone propulsion systems—including P50M, P65M, and P65V—drone operators may find the following points useful:

The ESC does not include an internal high-voltage pre-charge function. An external pre-charge circuit is required when powering on. Never connect the high-voltage source directly, as this would create an immediate short circuit with extremely high current, causing electrical arcing. Using a pre-charge circuit reduces inrush current and protects the electronic components.

To minimize electromagnetic interference (EMI), the motor and ESC metal housings should be properly grounded. Connect the two interfaces using grounding wires, ensuring the ESC grounding point is free of protective coatings and that the wires are installed without twists or external force.

The motor housing should also be connected to the drone's metal frame to form a complete grounding loop, allowing safe charge dissipation and preventing leakage risks.

ESC communication (CAN/RS485/PWM) should be isolated from the flight controller. The flight controller should be powered by an independent battery or via an isolated DC-DC converter. Common isolation methods include wiring isolation, power isolation, and signal isolation.

The frame of UAV drone must support its payload while remaining lightweight. For standard flat quadcopter drones, use carbon tubes ≥60 mm diameter with 2.5–3.0 mm wall thickness. Longer arms or coaxial drone setups require larger tube specifications.

Route ESC power and signal wires back through the carbon tube outlet to avoid drilling holes that weaken the arm. Carbon edges can abrade wires during flight. It is recommended to use protective grommets or sleeves to prevent short circuits.

By following the above safety and integration practices, UAV operators can fully leverage the efficiency, reliability, and performance advantages of HOBBYWING P-Series high-voltage propulsion systems in heavy-lift logistics applications.