Source : HOBBYWINGDate : 27th Sep 2025

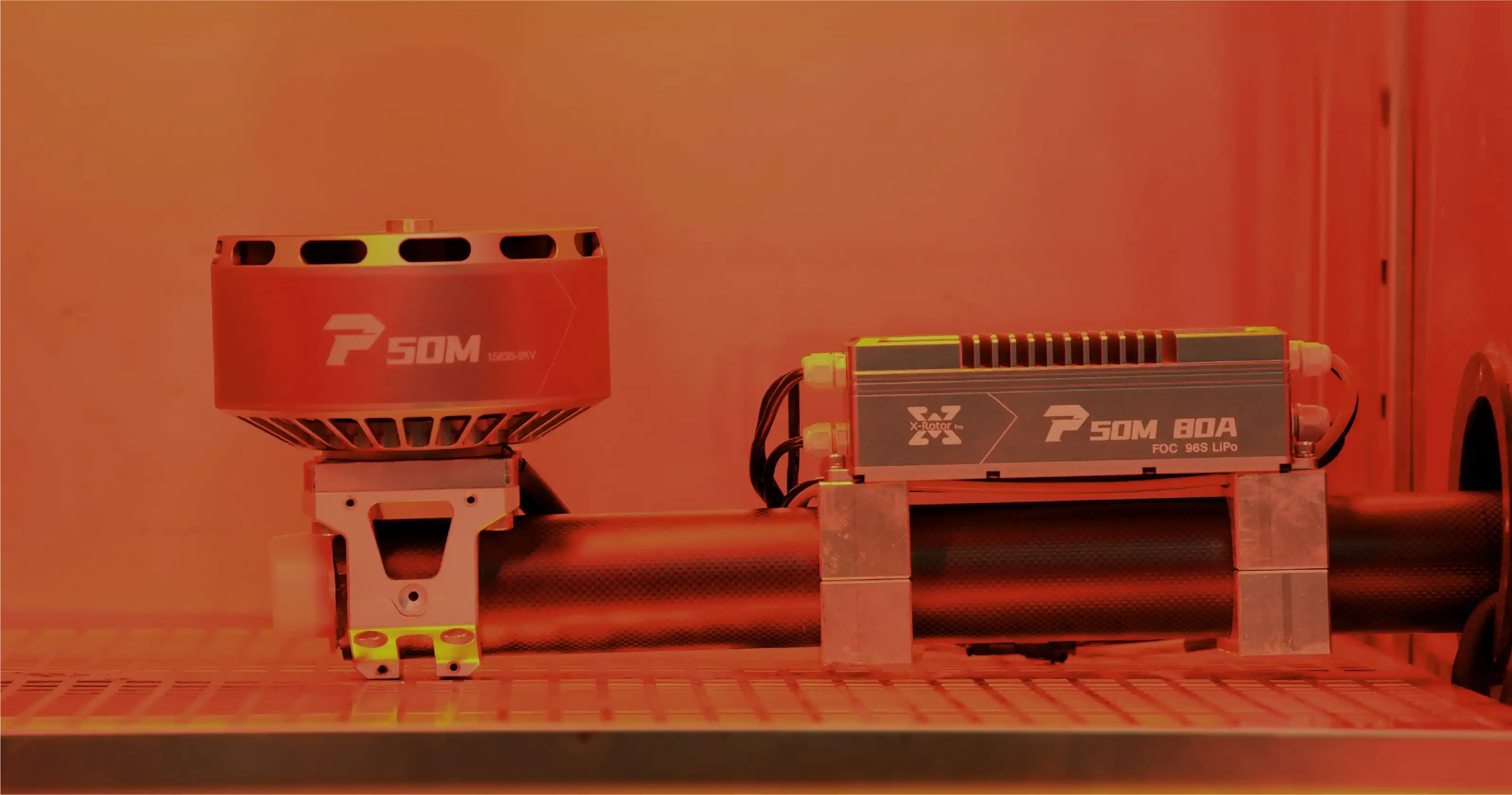

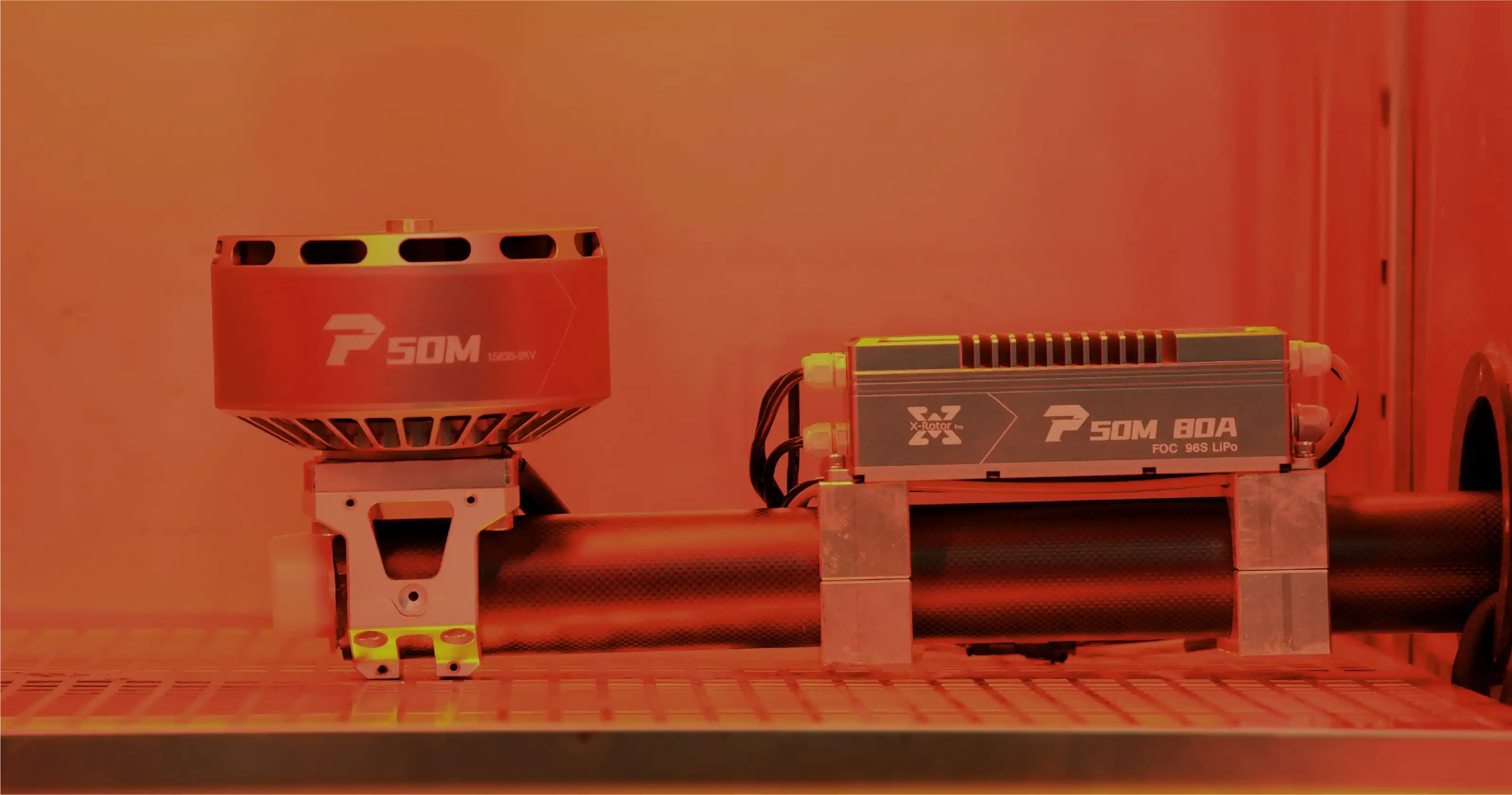

HOBBYWING P-Series high-voltage propulsion systems—P50M, P65M, and P65V—have demonstrated proven performance and reliability across diverse applications, earning broad market recognition since their launch. With their advantages in heat endurance, vibration tolerance, and significant weight reduction, they are becoming the ideal propulsion solution for heavy-lift multicopters and VTOL UAVs.

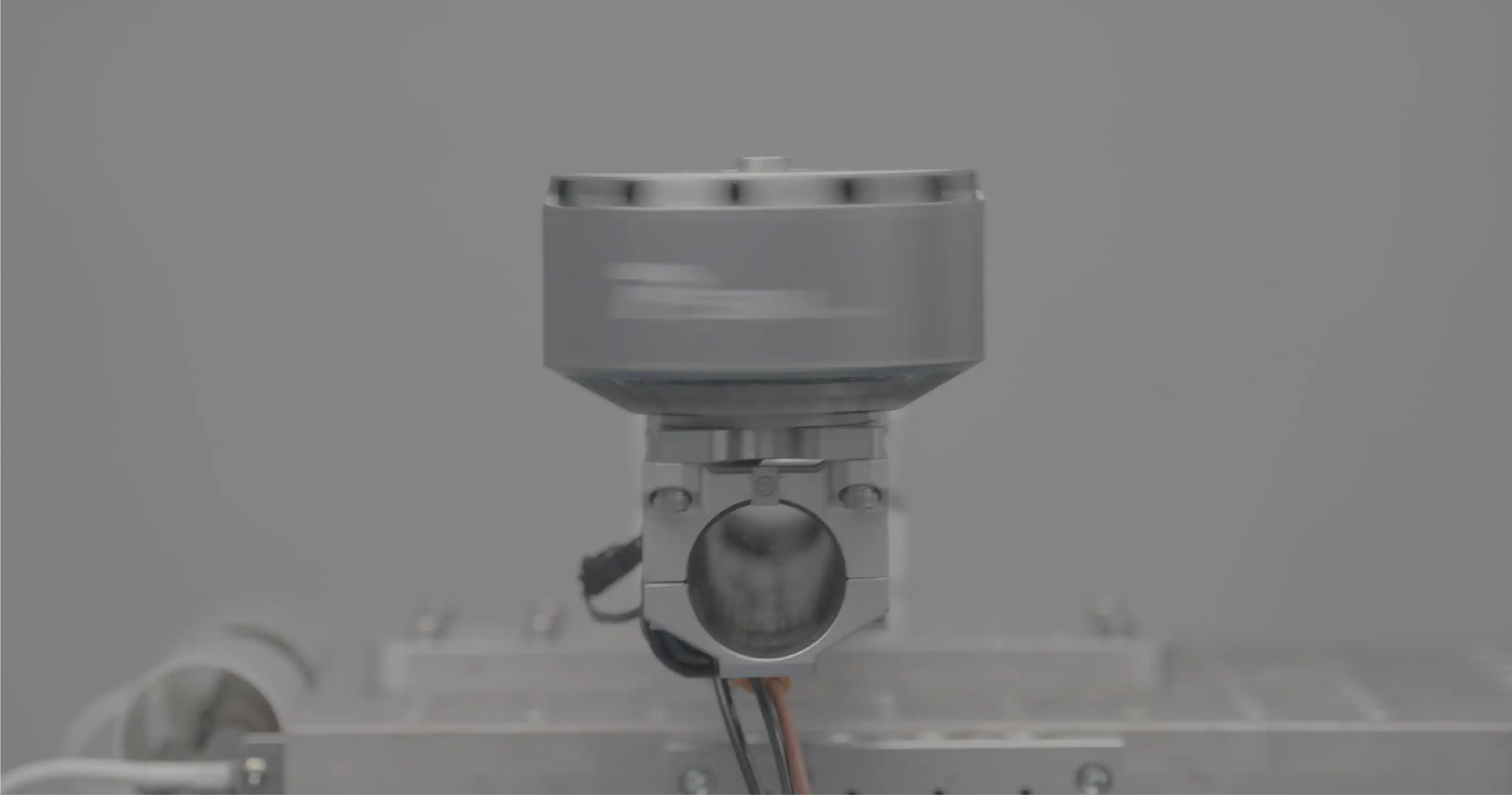

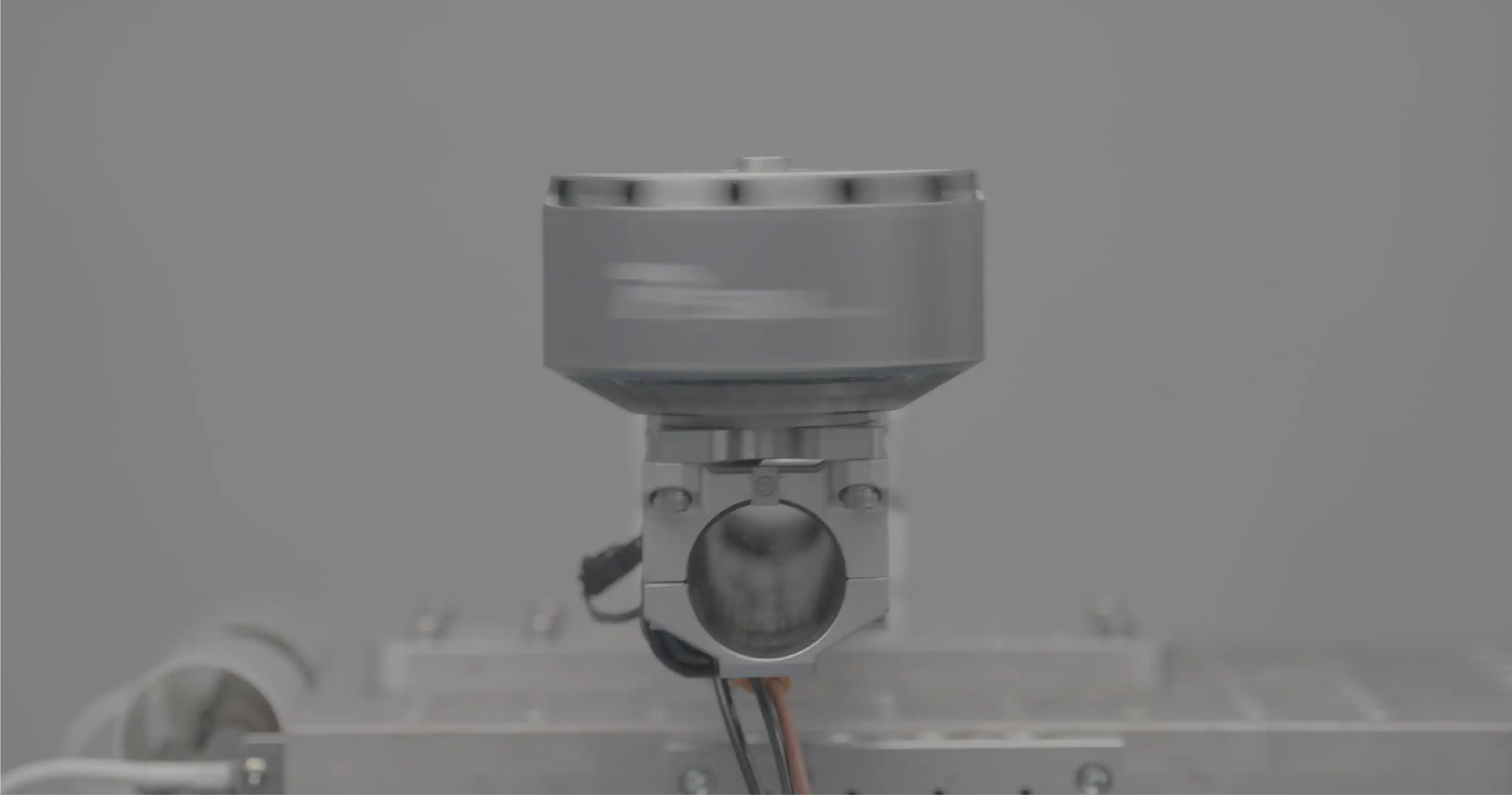

In rigorous high-temperature operation tests, the motor operated continuously for 24 hours at 85°C without performance degradation or failures. This enables drones operate stably and reliably in extreme environments such as deserts, oil and gas inspection fields, and other high-temperature operational scenarios.

Heavy-lift UAVs are subject to high vibration amplitude. The P-Series propulsion system leverages an integrated motor and ESC design to optimize vibration suppression and prevent in-flight stalls. Its adaptability across multiple airframe configurations further enhances operational reliability.

In 24-hour vibration endurance tests (10–600Hz, 10g), all components and fasteners remained intact, and the motor operated stably without anomalies. This exceptional vibration resilience ensures reliable performance even in strong winds and demanding mission conditions.

Compared with 18S propulsion systems of similar thrust, our P-Series 400V propulsion system requires only 10 AWG silicone wire (~70 g/m). In contrast, 18S systems use heavier 6 AWG wire, resulting in a weight saving of about 110 g per meter.

For a quadcopter with 60-inch propellers and a 2 m+ wheelbase, ESC input cables alone save about 880g. When combined with reductions in bus cables, power distribution boards, connectors, and motor phase wires, total weight savings easily exceed 1 kg. On larger platforms such as coaxial quadcopter or coaxial octocopters, weight savings can reach 3–5 kg, releasing more payload capacity for critical missions.

The P Series high-voltage power system, with its advantages of high temperature resistance, vibration resistance, and significant weight reduction, is becoming an ideal propulsion solution for large heavy-lift drones.

In the future, HOBBYWING will continue to expand the P Series product lineup, offering more diverse and innovative high-quality products to provide more efficient and reliable high-voltage propulsion solutions for heavy-duty industrial drones. Stay tuned!

Source:HOBBYWINGDate: 27th Sep 2025

HOBBYWING P-Series high-voltage propulsion systems—P50M, P65M, and P65V—have demonstrated proven performance and reliability across diverse applications, earning broad market recognition since their launch. With their advantages in heat endurance, vibration tolerance, and significant weight reduction, they are becoming the ideal propulsion solution for heavy-lift multicopters and VTOL UAVs.

In rigorous high-temperature operation tests, the motor operated continuously for 24 hours at 85°C without performance degradation or failures. This enables drones operate stably and reliably in extreme environments such as deserts, oil and gas inspection fields, and other high-temperature operational scenarios.

Heavy-lift UAVs are subject to high vibration amplitude. The P-Series propulsion system leverages an integrated motor and ESC design to optimize vibration suppression and prevent in-flight stalls. Its adaptability across multiple airframe configurations further enhances operational reliability.

In 24-hour vibration endurance tests (10–600Hz, 10g), all components and fasteners remained intact, and the motor operated stably without anomalies. This exceptional vibration resilience ensures reliable performance even in strong winds and demanding mission conditions.

Compared with 18S propulsion systems of similar thrust, our P-Series 400V propulsion system requires only 10 AWG silicone wire (~70 g/m). In contrast, 18S systems use heavier 6 AWG wire, resulting in a weight saving of about 110 g per meter.

For a quadcopter with 60-inch propellers and a 2 m+ wheelbase, ESC input cables alone save about 880g. When combined with reductions in bus cables, power distribution boards, connectors, and motor phase wires, total weight savings easily exceed 1 kg. On larger platforms such as coaxial quadcopter or coaxial octocopters, weight savings can reach 3–5 kg, releasing more payload capacity for critical missions.

The P Series high-voltage power system, with its advantages of high temperature resistance, vibration resistance, and significant weight reduction, is becoming an ideal propulsion solution for large heavy-lift drones.

In the future, HOBBYWING will continue to expand the P Series product lineup, offering more diverse and innovative high-quality products to provide more efficient and reliable high-voltage propulsion solutions for heavy-duty industrial drones. Stay tuned!