Source : HOBBYWINGDate : 20th Oct 2025

Hobbywing announces the release of the H13 Coaxial Integrated Propulsion System, specifically designed for heavy-lift UAV applications. With exceptional performance and high reliability, H13 drone propulsion system boasts a rated thrust of 45kg, a maximum thrust of over 110kg, and a recommended takeoff weight of 180kg (for quadcopters and octocopters). The system can carry a maximum mission load of 100kg, making it ideal for a variety of drone applications such as cargo lifting, logistics transportation, fire fighting, and emergency rescue.

HOBBYWING H13 coaxial drone propulsion system operates efficiently in environments ranging from -40°C to 65°C, meeting the needs of UAV transport tasks in extremely cold regions. Moreover, the H13 propulsion system is built on a 100V high-voltage platform, supporting up to 28S LiPo batteries. Compared to a 24S system, this reduces current by 15%, lowers discharge rates, extends service life, enhances user-friendliness, and makes flights safer.

HOBBYWING’s brand-new H13 UAV integrated propulsion system is engineered for heavy-lift coaxial control characteristics. It features a 3° tilt angle clamp mount that quickly adapts to various flight control systems, improving flight control efficiency. This design significantly enhances the maneuverability and hover stability of heavy-duty multirotor drones.

H13 drone propulsion system’s electronic speed controller (ESC) uses automotive-grade temperature-resistant components, with an operating temperature range of -40°C to 65°C. The motors are made from high-temperature-resistant materials, the propellers are crafted from high-reliability carbon fiber, and the motor mounts are formed from high-strength aluminum alloy, ensuring the system’s durability and stability.

Additionally, the ESC of the Hobbywing H13 coaxial integrated propulsion system is designed with a dual-side tube clip holder layout, which can effectively utilize the propeller airflow for continuous heat dissipation, easily addressing harsh heavy-duty flight tasks.

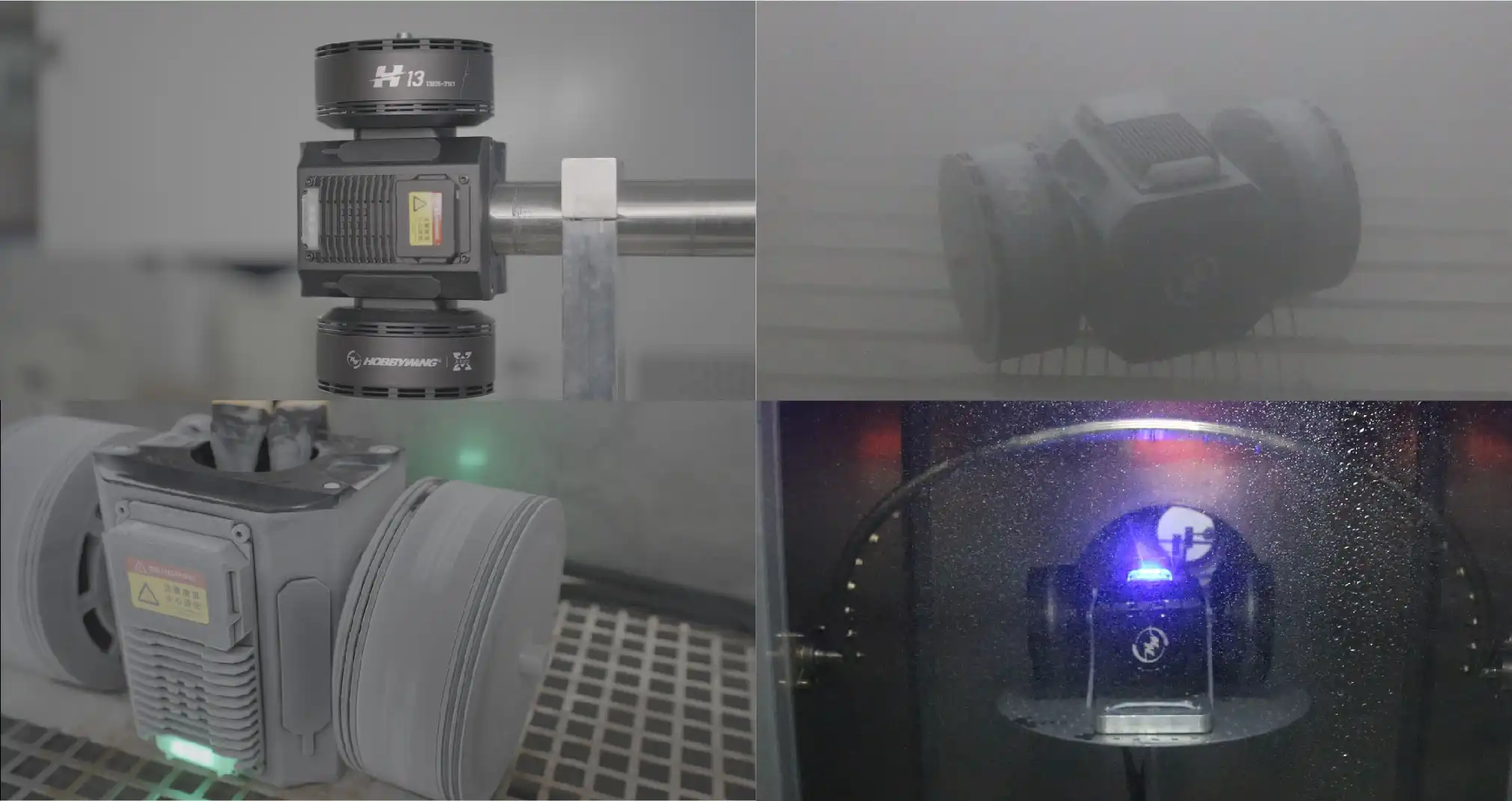

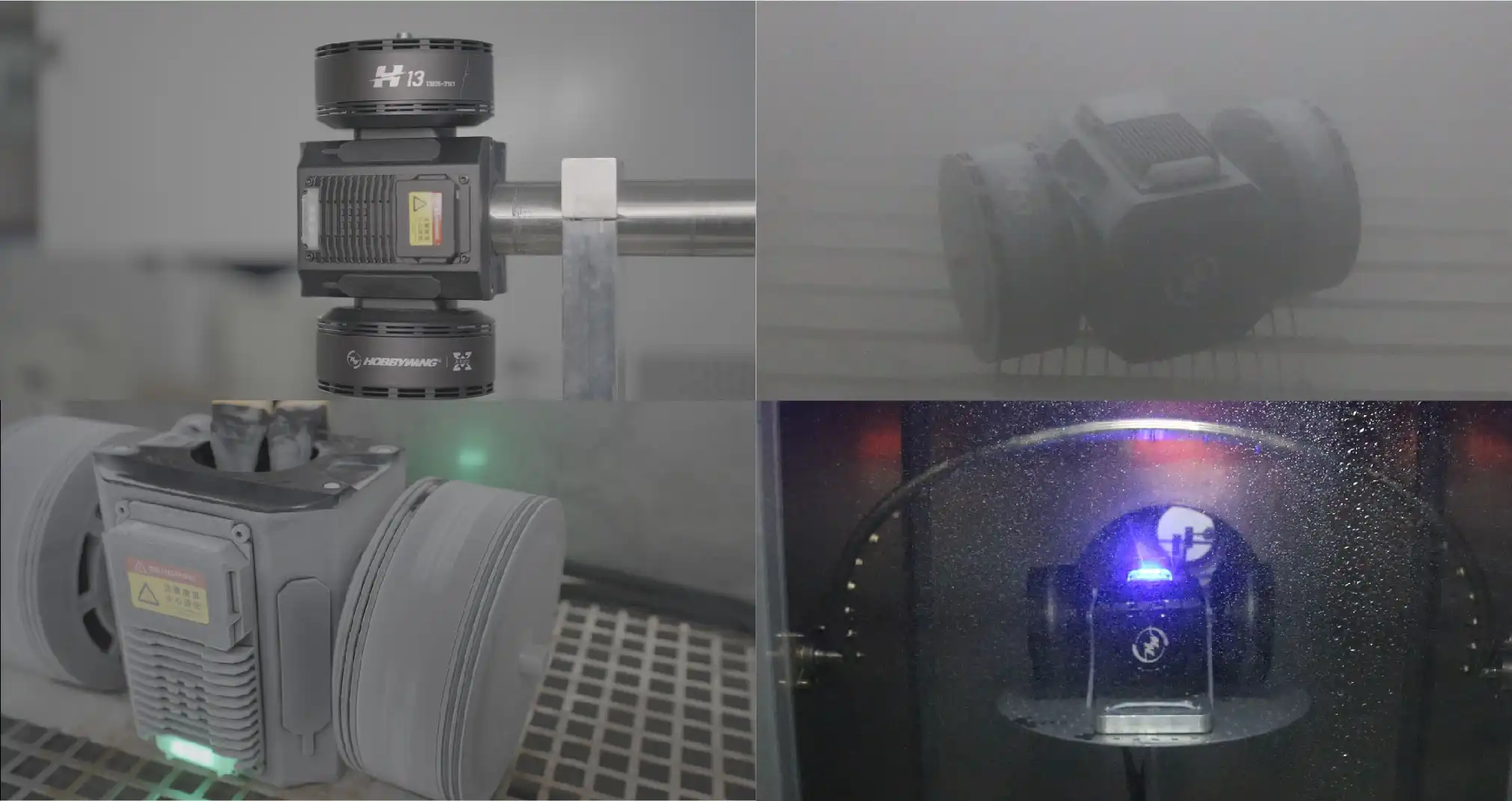

H13 coaxial propulsion system for heavy-lift multirotor drones passes through the lab life test for over 1,000 hours in the temperature range of -40°C to 65°C and over 500 hours of real-flight verification. In further, this system undergoes stringent industry tests, including drive compatibility tests, temperature/humidity combined vibration tests, and high and low-temperature tests. These ensure the stable operation of the propulsion system at all times in various complex environments.

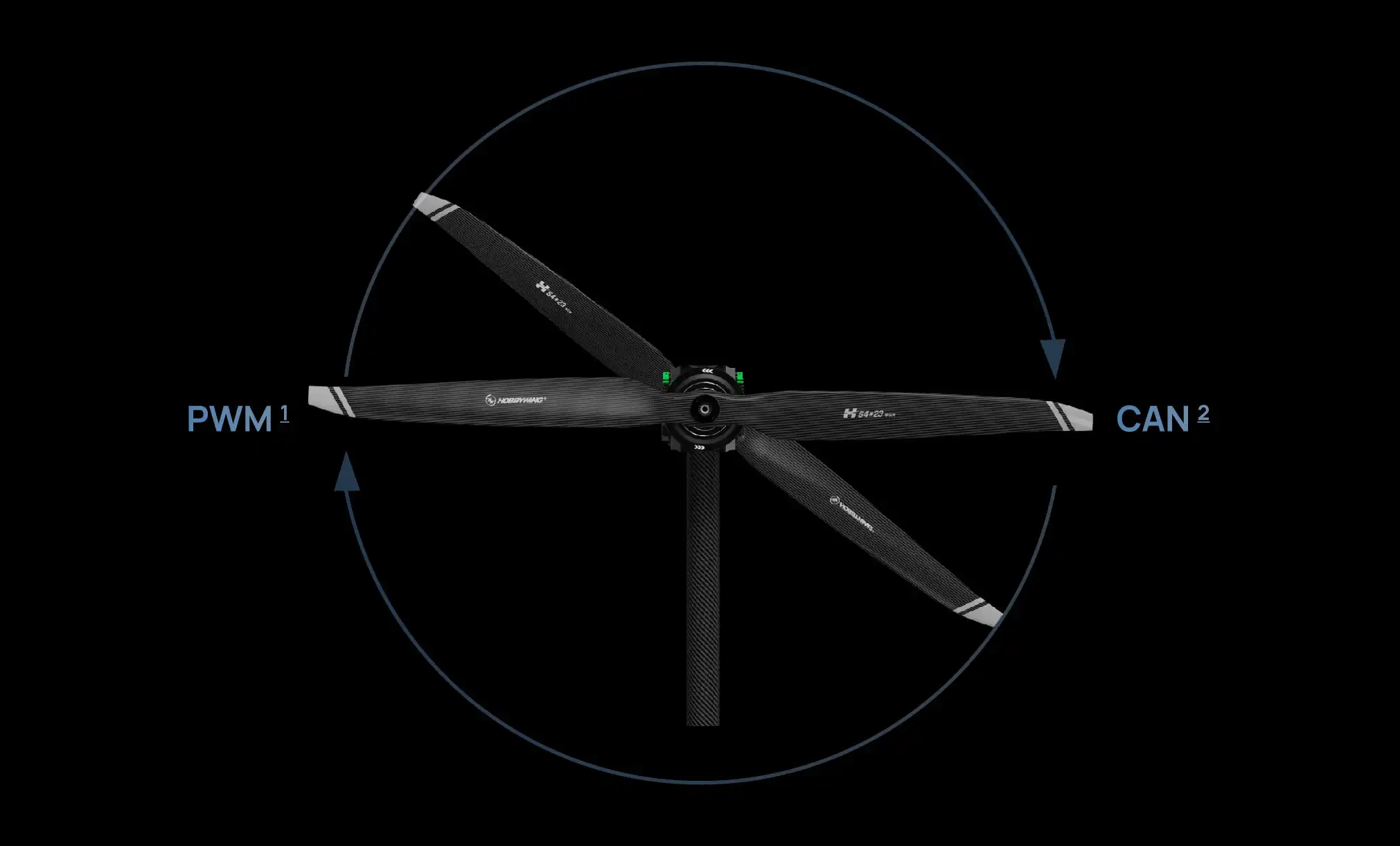

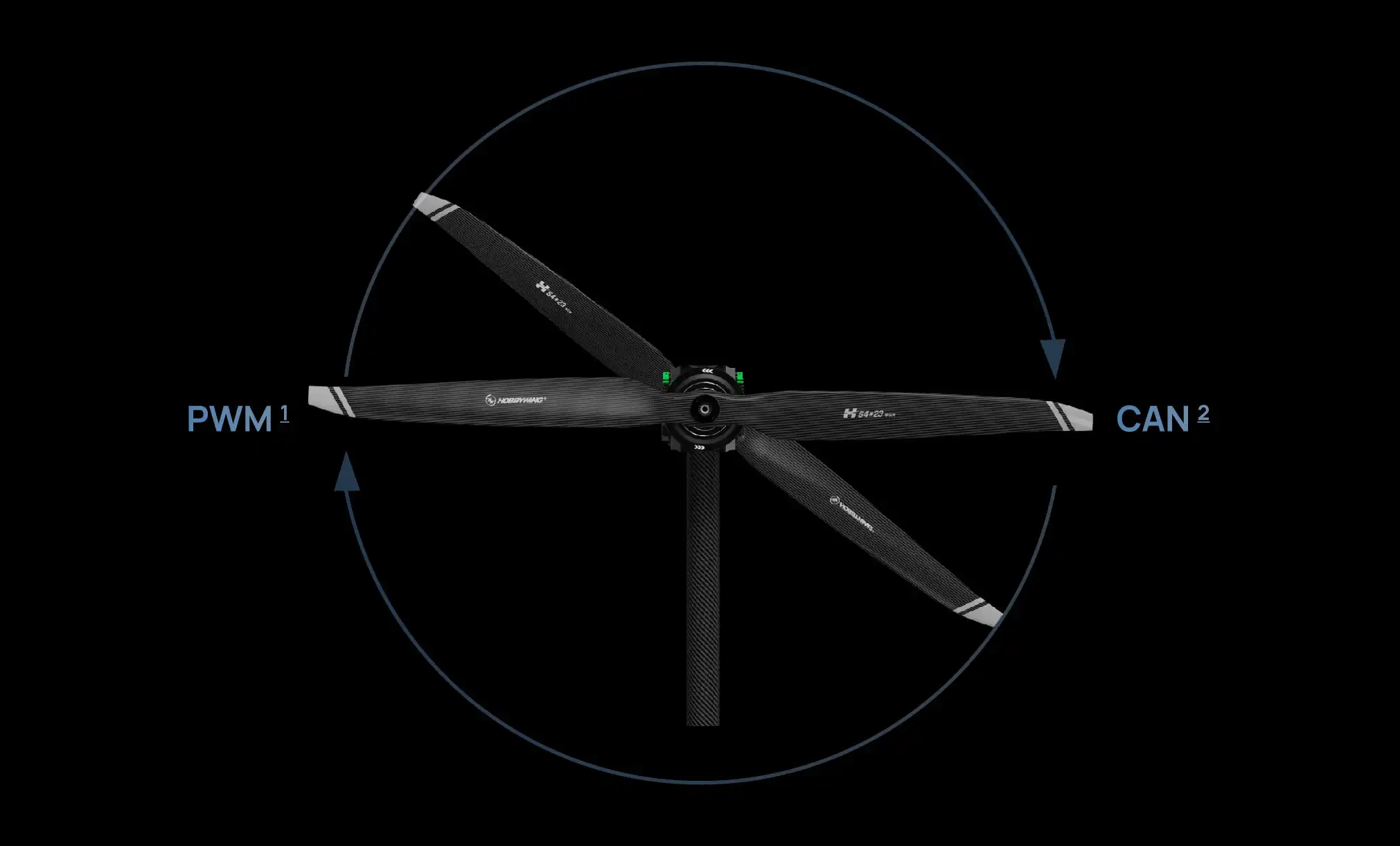

HOBBYWING H13 drone propulsion system adopts a dual-throttle control with CAN bus digital control and PWM analog signals, significantly enhancing the system’s real-time response and anti-interference capability.

The aluminum sleeve design of the carbon tube internal support allows the tube clip holder,the arm tube, and the internal support aluminum sleeve to penetrate and lock firmly in four directions. This can effectively prevent the H13 propulsion system from loosening or twisting in the harsh flight vibration environment.

H13 drone propulsion system also integrates multiple intelligent protection mechanisms, including over-current, stalling, throttle loss, temperature anomaly monitoring, and low and high voltage protection, further guaranteeing flight safety.

Equipped with a built-in intelligent monitoring system, H13 UAV propulsion system provides real-time fault status updates through an LED display, allowing for quick diagnosis. The system communicates real-time flight data with the flight controller via CAN interface, monitoring key parameters such as RPM, throttle, current, voltage, and temperature. This feature supports data analysis and risk warnings. Additionally, the ESC of H15 has a built-in black box that stores operational data and fault codes for quick location and diagnosis of faults.

Hobbywing H13 propulsion system features a modular design, with a highly integrated motor and ESC, eliminating the need for complex assembly processes and improving installation efficiency. It is adapted to 60mm tube diameter and 2.5mm wall thickness after strength analysis and reliability verification, which can be seamlessly integrated with the mainstream heavy-lift frames in the market.

H13 propulsion system for heavy-duty multirotor drones supports DroneCAN protocol and intercommunication with multiple mainstream flight control systems, such as ArduPilot open source ecosystem, VK, Byaero and Jiyi. It also supports CAN communication to build an intelligent flight ecosystem.

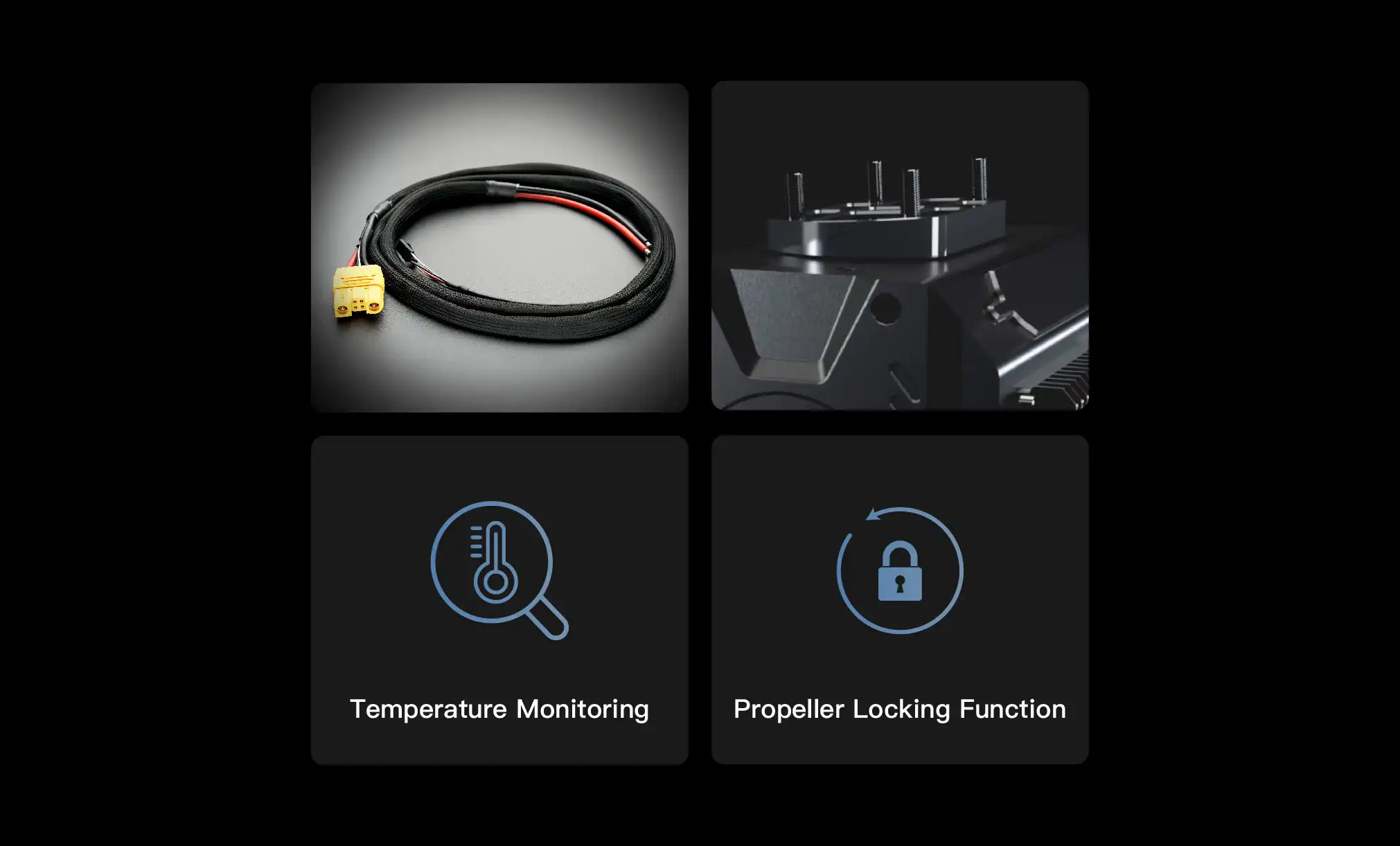

To cater to a wide range of user requirements, HOBBYWING offers customizable services. Users can select from extension cables of different sizes and lengths, different tilt angles for the tube clip holder, and the option to add motor temperature monitoring and propeller-locking functionality. Carbon fiber non-folding or folding propellers are also available, further optimizing flight performance.

Source:HOBBYWINGDate: 20th Oct 2025

Hobbywing announces the release of the H13 Coaxial Integrated Propulsion System, specifically designed for heavy-lift UAV applications. With exceptional performance and high reliability, H13 drone propulsion system boasts a rated thrust of 45kg, a maximum thrust of over 110kg, and a recommended takeoff weight of 180kg (for quadcopters and octocopters). The system can carry a maximum mission load of 100kg, making it ideal for a variety of drone applications such as cargo lifting, logistics transportation, fire fighting, and emergency rescue.

HOBBYWING H13 coaxial drone propulsion system operates efficiently in environments ranging from -40°C to 65°C, meeting the needs of UAV transport tasks in extremely cold regions. Moreover, the H13 propulsion system is built on a 100V high-voltage platform, supporting up to 28S LiPo batteries. Compared to a 24S system, this reduces current by 15%, lowers discharge rates, extends service life, enhances user-friendliness, and makes flights safer.

HOBBYWING’s brand-new H13 UAV integrated propulsion system is engineered for heavy-lift coaxial control characteristics. It features a 3° tilt angle clamp mount that quickly adapts to various flight control systems, improving flight control efficiency. This design significantly enhances the maneuverability and hover stability of heavy-duty multirotor drones.

H13 drone propulsion system’s electronic speed controller (ESC) uses automotive-grade temperature-resistant components, with an operating temperature range of -40°C to 65°C. The motors are made from high-temperature-resistant materials, the propellers are crafted from high-reliability carbon fiber, and the motor mounts are formed from high-strength aluminum alloy, ensuring the system’s durability and stability.

Additionally, the ESC of the Hobbywing H13 coaxial integrated propulsion system is designed with a dual-side tube clip holder layout, which can effectively utilize the propeller airflow for continuous heat dissipation, easily addressing harsh heavy-duty flight tasks.

H13 coaxial propulsion system for heavy-lift multirotor drones passes through the lab life test for over 1,000 hours in the temperature range of -40°C to 65°C and over 500 hours of real-flight verification. In further, this system undergoes stringent industry tests, including drive compatibility tests, temperature/humidity combined vibration tests, and high and low-temperature tests. These ensure the stable operation of the propulsion system at all times in various complex environments.

HOBBYWING H13 drone propulsion system adopts a dual-throttle control with CAN bus digital control and PWM analog signals, significantly enhancing the system’s real-time response and anti-interference capability.

The aluminum sleeve design of the carbon tube internal support allows the tube clip holder,the arm tube, and the internal support aluminum sleeve to penetrate and lock firmly in four directions. This can effectively prevent the H13 propulsion system from loosening or twisting in the harsh flight vibration environment.

H13 drone propulsion system also integrates multiple intelligent protection mechanisms, including over-current, stalling, throttle loss, temperature anomaly monitoring, and low and high voltage protection, further guaranteeing flight safety.

Equipped with a built-in intelligent monitoring system, H13 UAV propulsion system provides real-time fault status updates through an LED display, allowing for quick diagnosis. The system communicates real-time flight data with the flight controller via CAN interface, monitoring key parameters such as RPM, throttle, current, voltage, and temperature. This feature supports data analysis and risk warnings. Additionally, the ESC of H15 has a built-in black box that stores operational data and fault codes for quick location and diagnosis of faults.

Hobbywing H13 propulsion system features a modular design, with a highly integrated motor and ESC, eliminating the need for complex assembly processes and improving installation efficiency. It is adapted to 60mm tube diameter and 2.5mm wall thickness after strength analysis and reliability verification, which can be seamlessly integrated with the mainstream heavy-lift frames in the market.

H13 propulsion system for heavy-duty multirotor drones supports DroneCAN protocol and intercommunication with multiple mainstream flight control systems, such as ArduPilot open source ecosystem, VK, Byaero and Jiyi. It also supports CAN communication to build an intelligent flight ecosystem.

To cater to a wide range of user requirements, HOBBYWING offers customizable services. Users can select from extension cables of different sizes and lengths, different tilt angles for the tube clip holder, and the option to add motor temperature monitoring and propeller-locking functionality. Carbon fiber non-folding or folding propellers are also available, further optimizing flight performance.