|

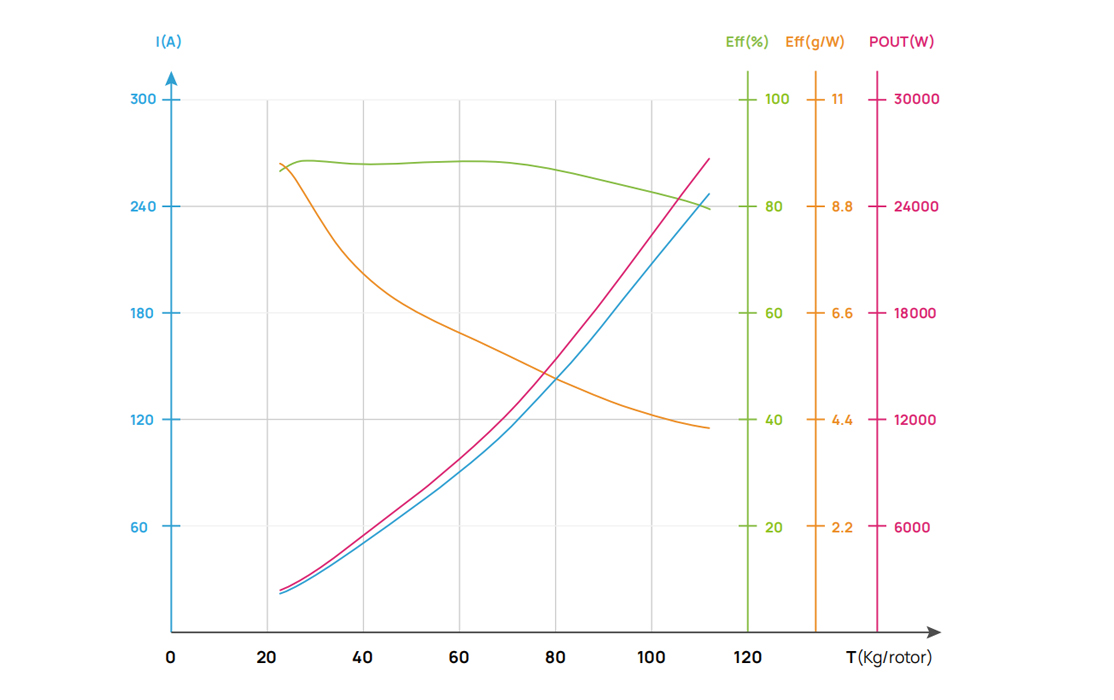

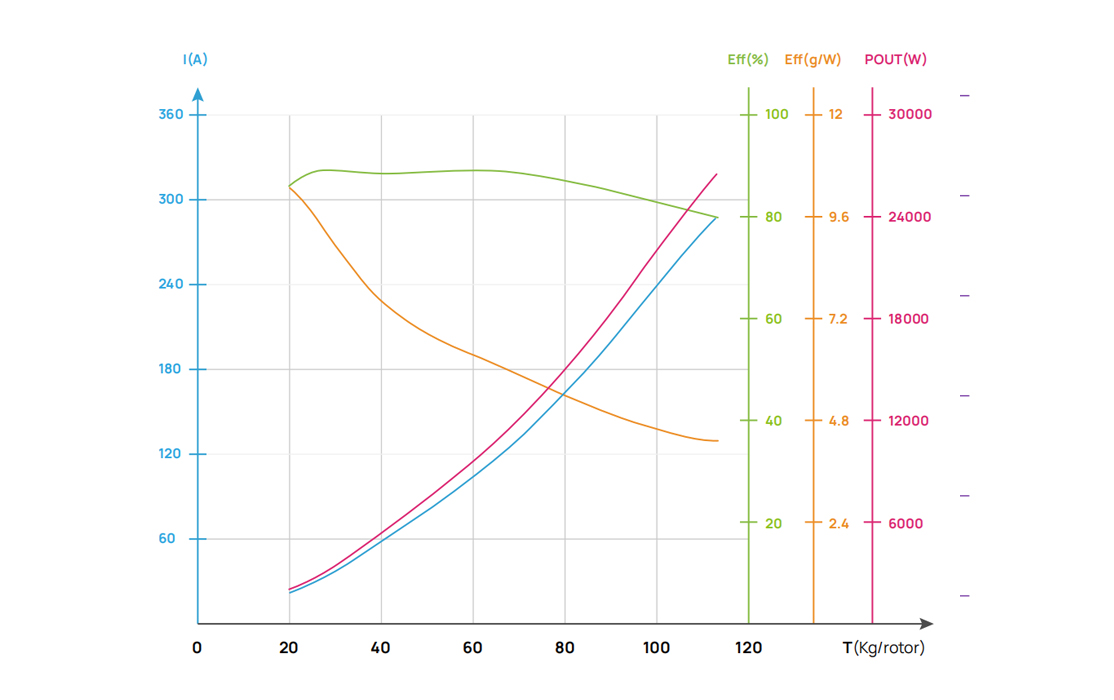

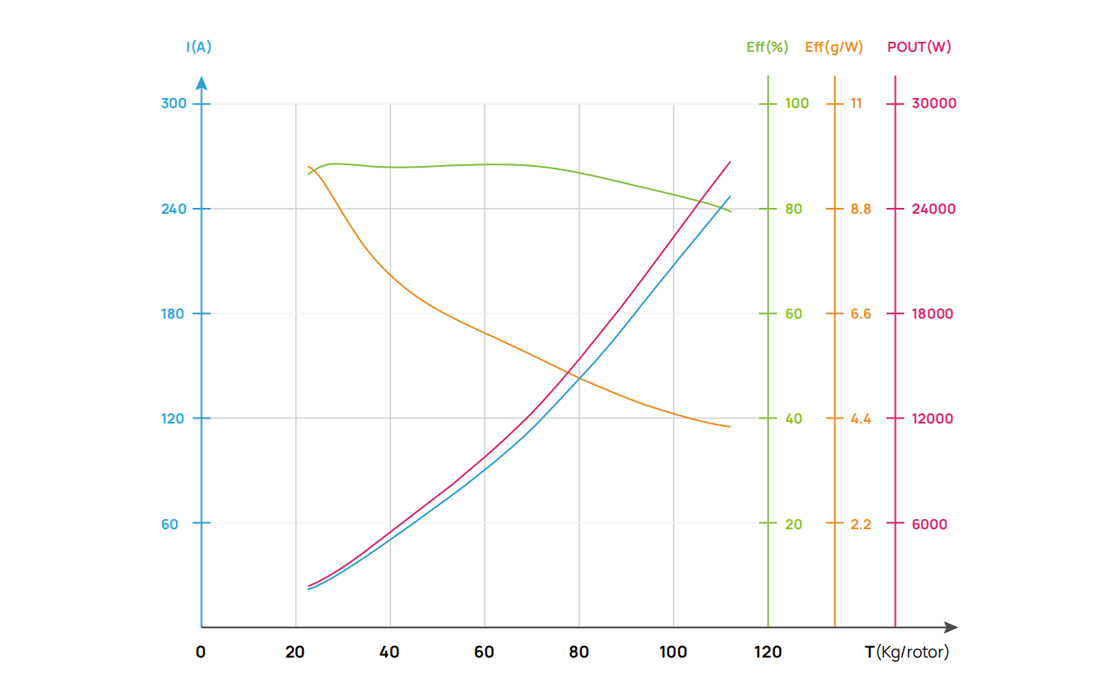

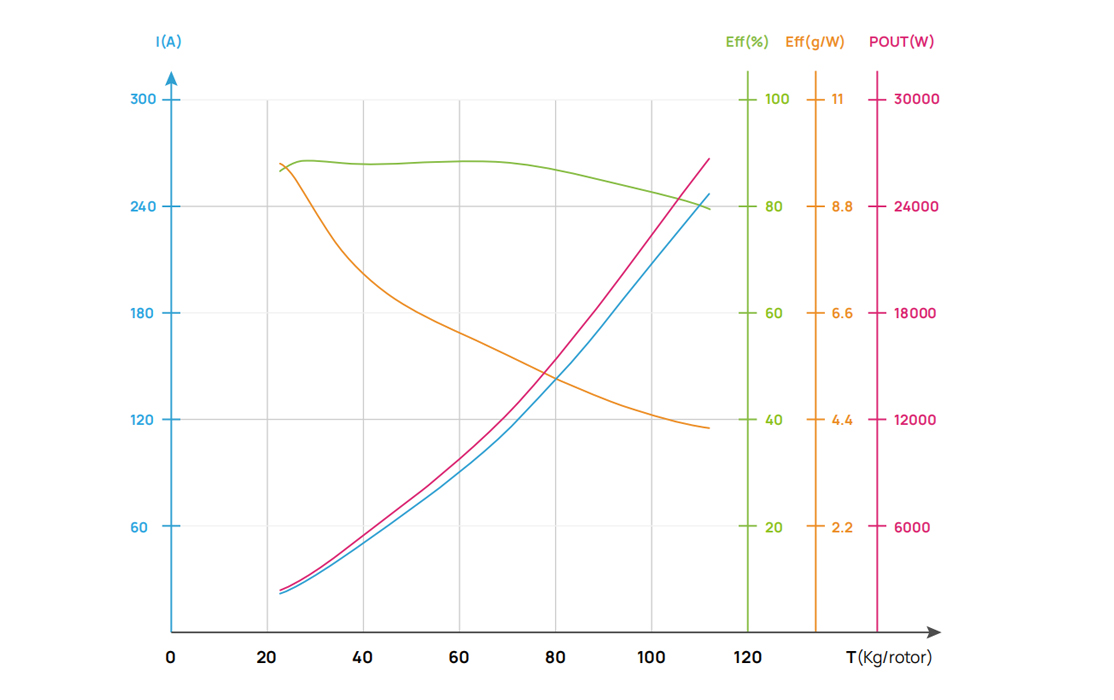

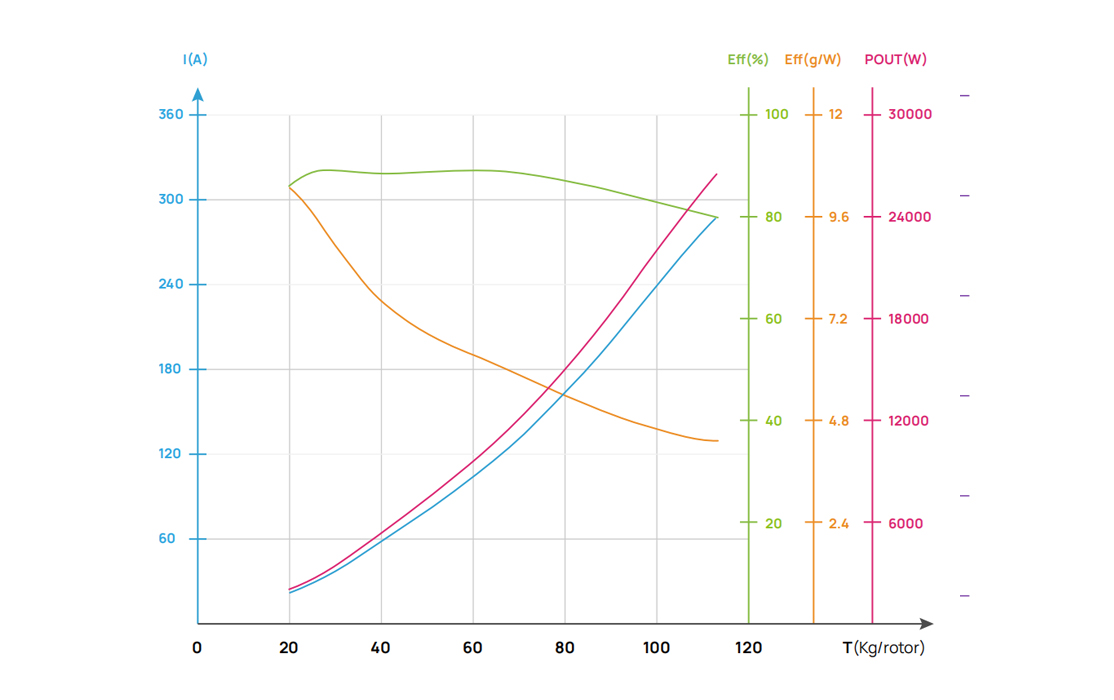

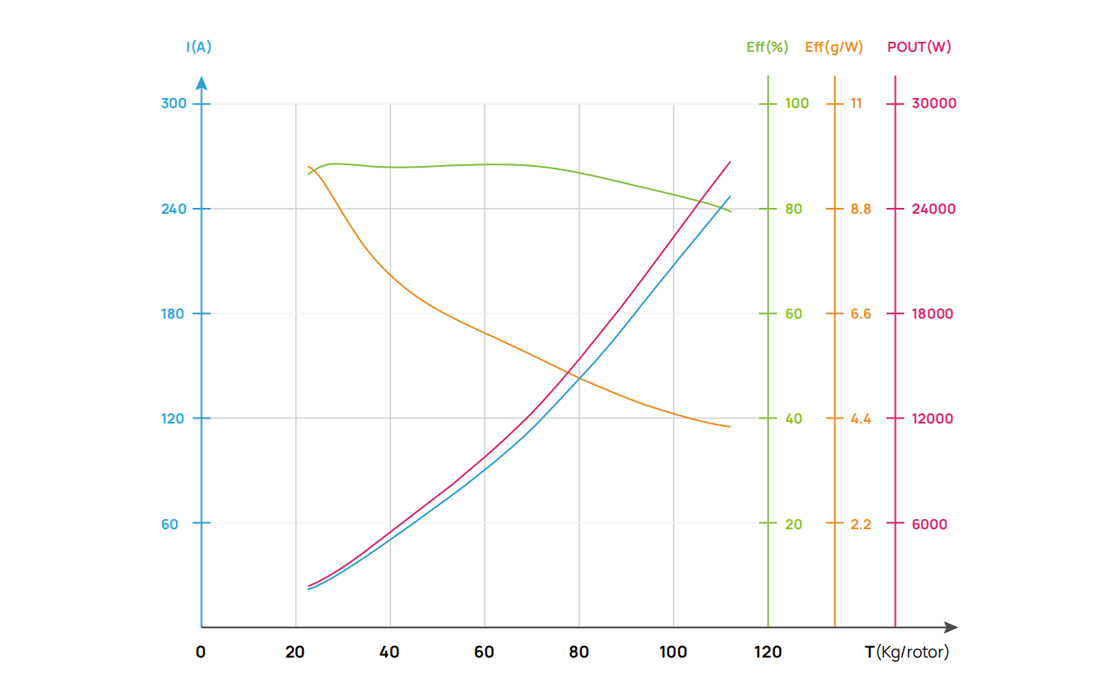

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

92V (24S LiPo) |

MSC 54x20 |

33% |

17501 |

18.1 |

1667 |

86 |

10.5 |

86℃ |

|

35% |

18490 |

19.5 |

1794 |

86 |

10.3 |

|||

|

37% |

20581 |

22.5 |

2066 |

87 |

10.0 |

|||

|

39% |

22800 |

25.8 |

2372 |

88 |

9.6 |

|||

|

41% |

25125 |

29.5 |

2719 |

89 |

9.6 |

|||

|

43% |

27541 |

33.8 |

3109 |

89 |

8.9 |

|||

|

45% |

30036 |

38.5 |

3539 |

89 |

8.5 |

|||

|

47% |

32603 |

43.5 |

4005 |

89 |

8.1 |

|||

|

49% |

35239 |

48.9 |

4502 |

89 |

7.8 |

|||

|

51% |

37944 |

54.6 |

5028 |

89 |

7.5 |

|||

|

53% |

40718 |

60.6 |

5580 |

89 |

7.3 |

|||

|

55% |

45125 |

71.8 |

6339 |

90 |

6.8 |

|||

|

58% |

47982 |

77.9 |

7170 |

90 |

6.7 |

|||

|

61% |

52586 |

87.8 |

8076 |

90 |

6.5 |

|||

|

63% |

55764 |

95.6 |

8795 |

90 |

6.3 |

|||

|

65% |

59031 |

103.9 |

9565 |

90 |

6.2 |

|||

|

68% |

64093 |

117.7 |

10830 |

90 |

5.9 |

|||

|

71% |

69330 |

133.0 |

12241 |

89 |

5.7 |

|||

|

75% |

76515 |

156.0 |

14359 |

89 |

5.3 |

|||

|

80% |

85567 |

188.2 |

17316 |

87 |

4.9 |

|||

|

85% |

94162 |

221.5 |

20384 |

86 |

4.6 |

|||

|

100% |

106991 |

273.6 |

25177 |

83 |

4.2 |

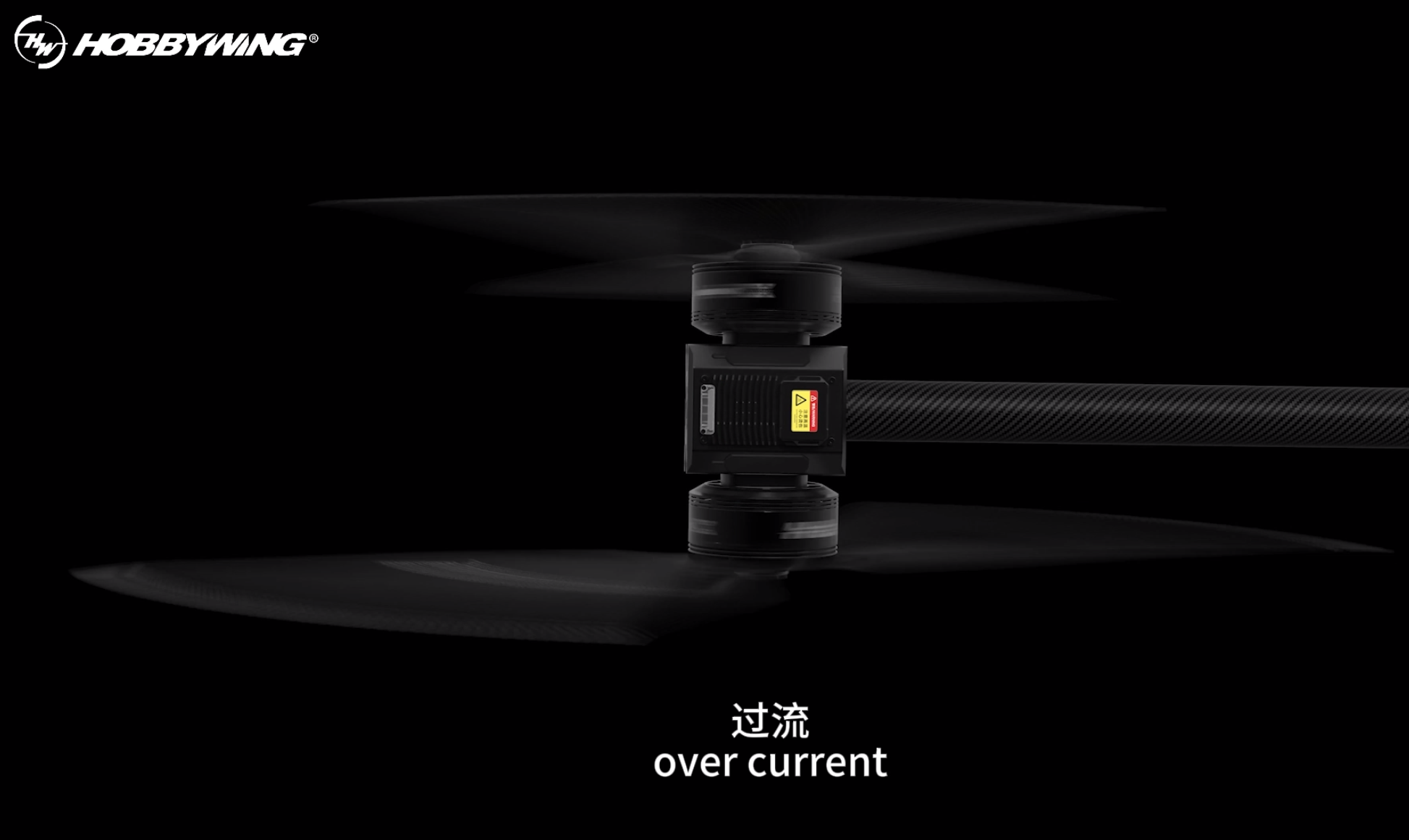

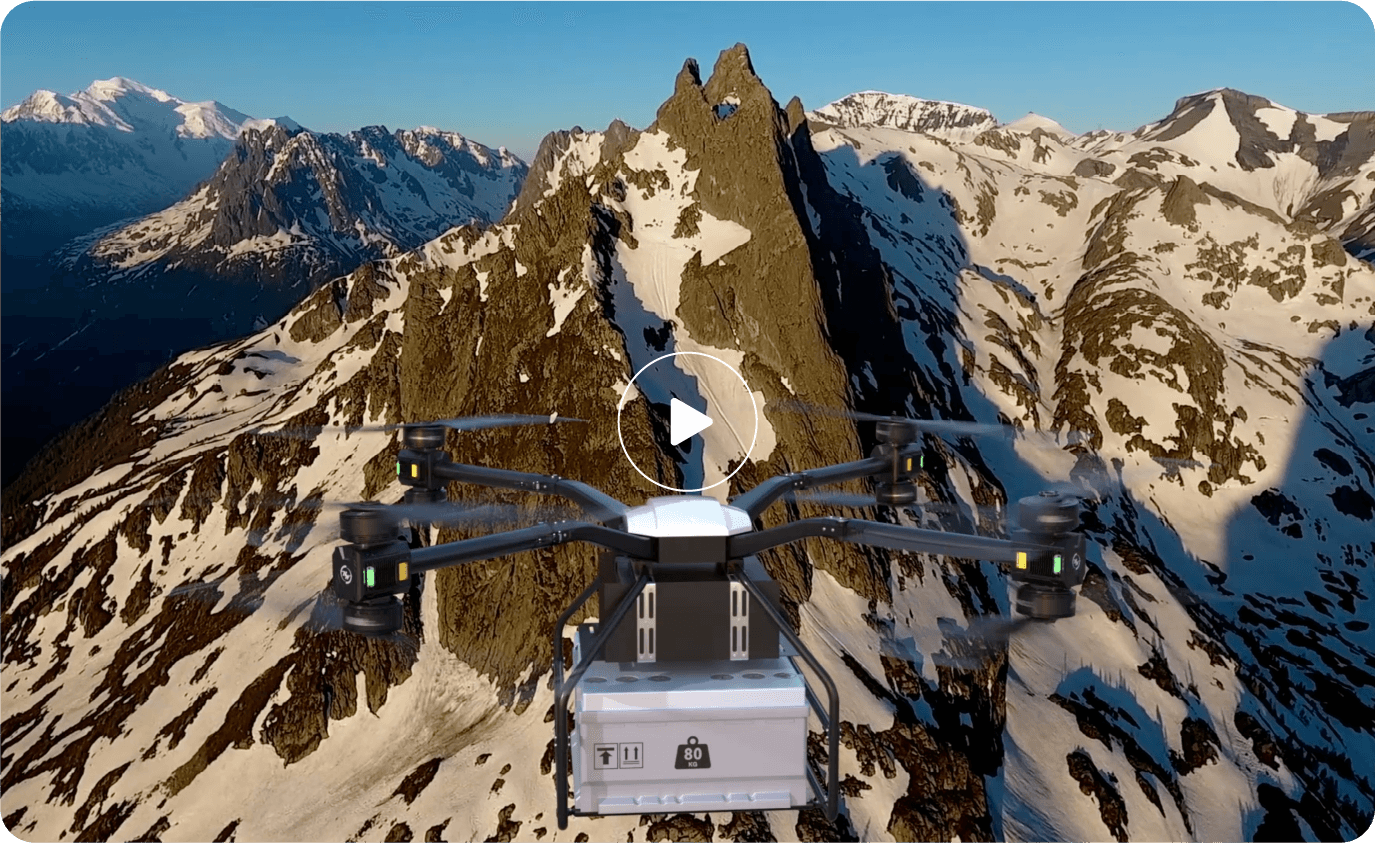

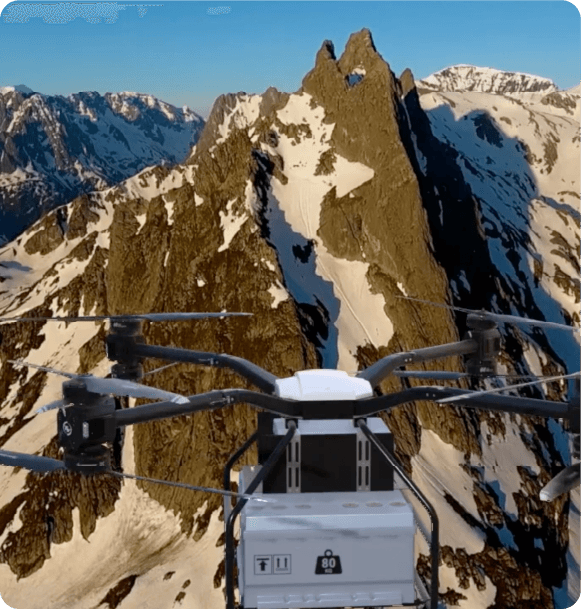

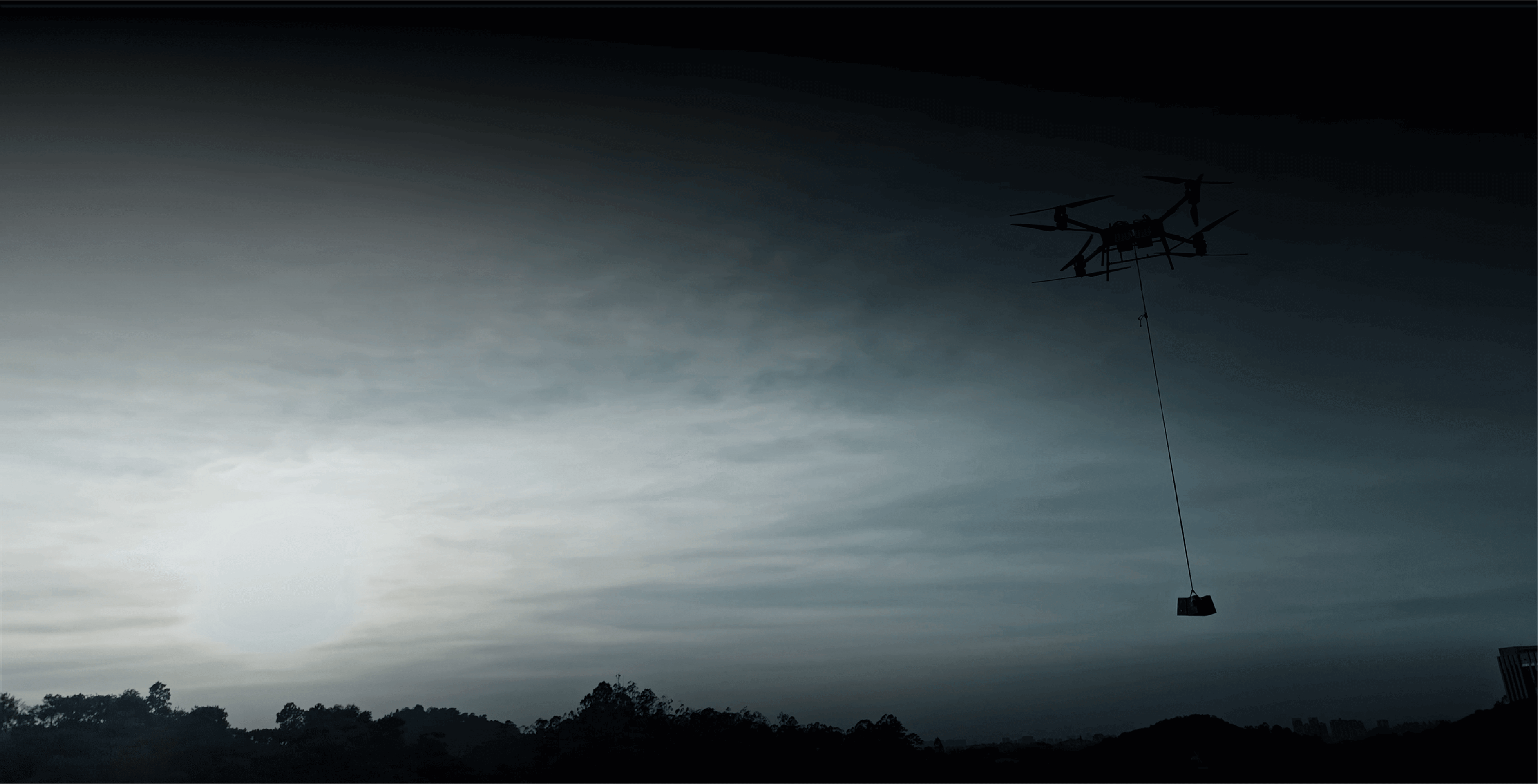

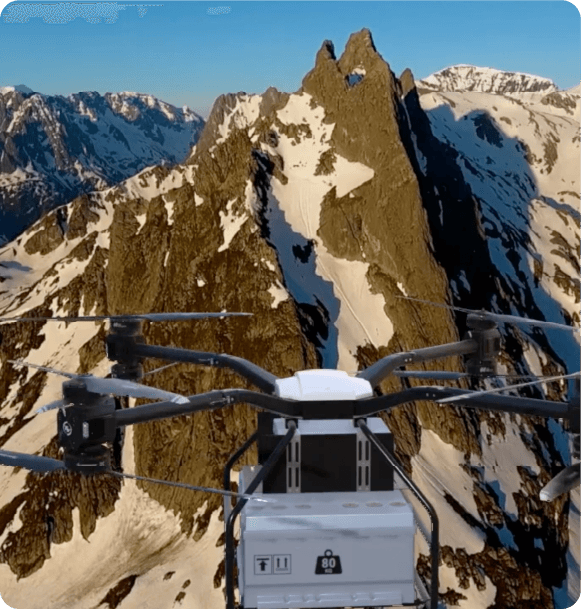

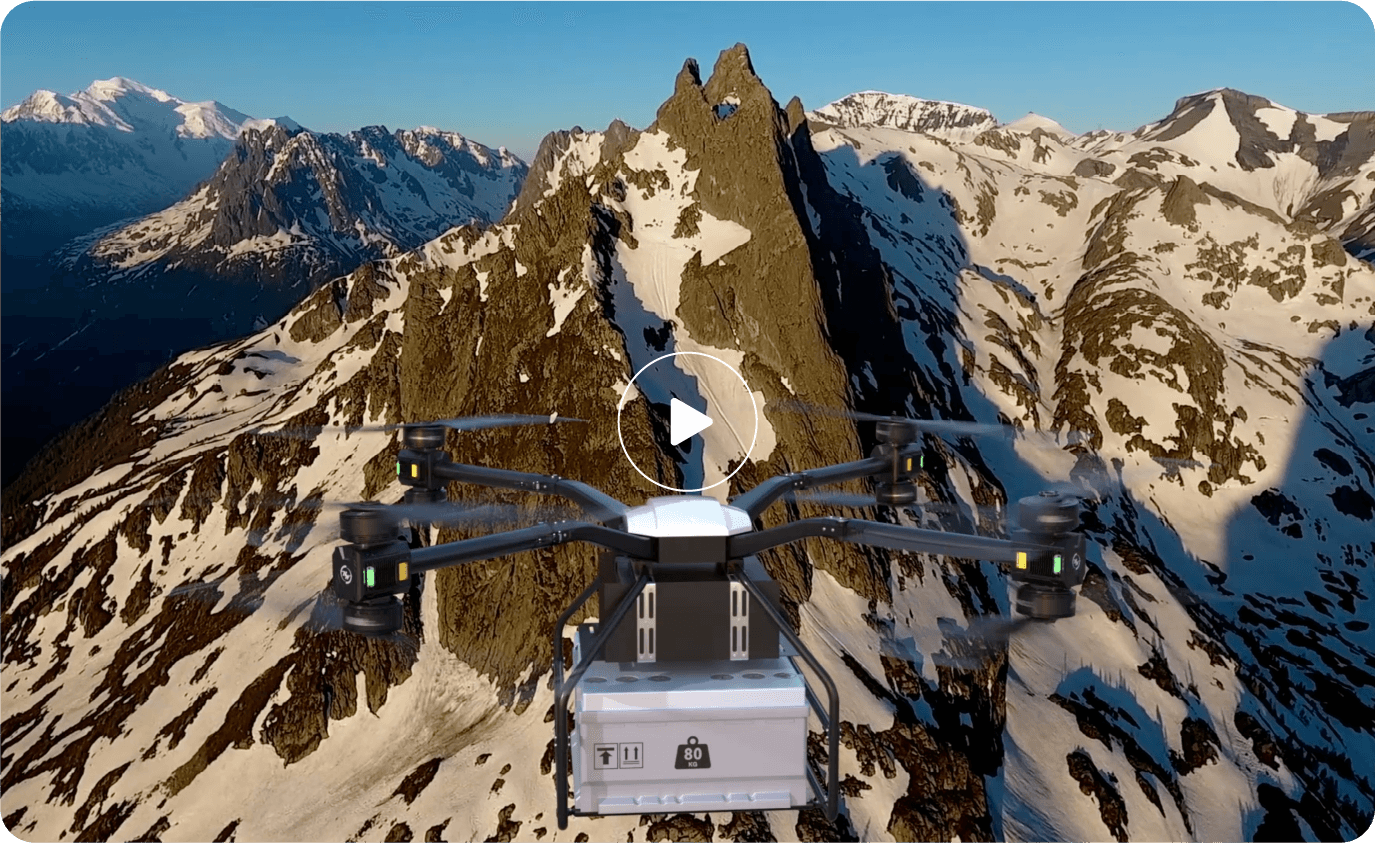

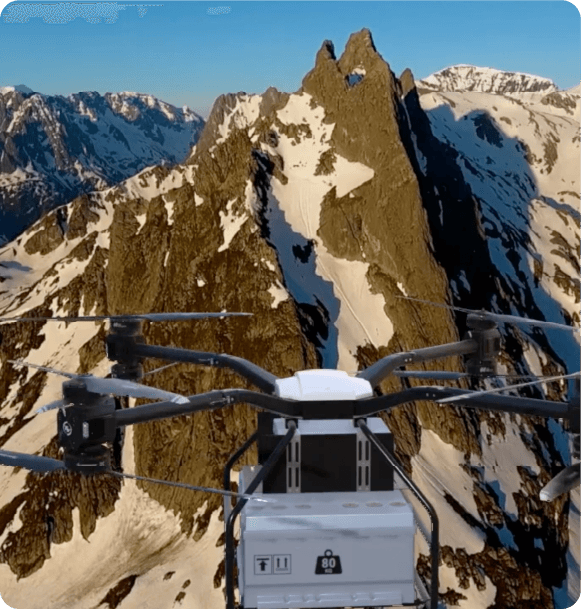

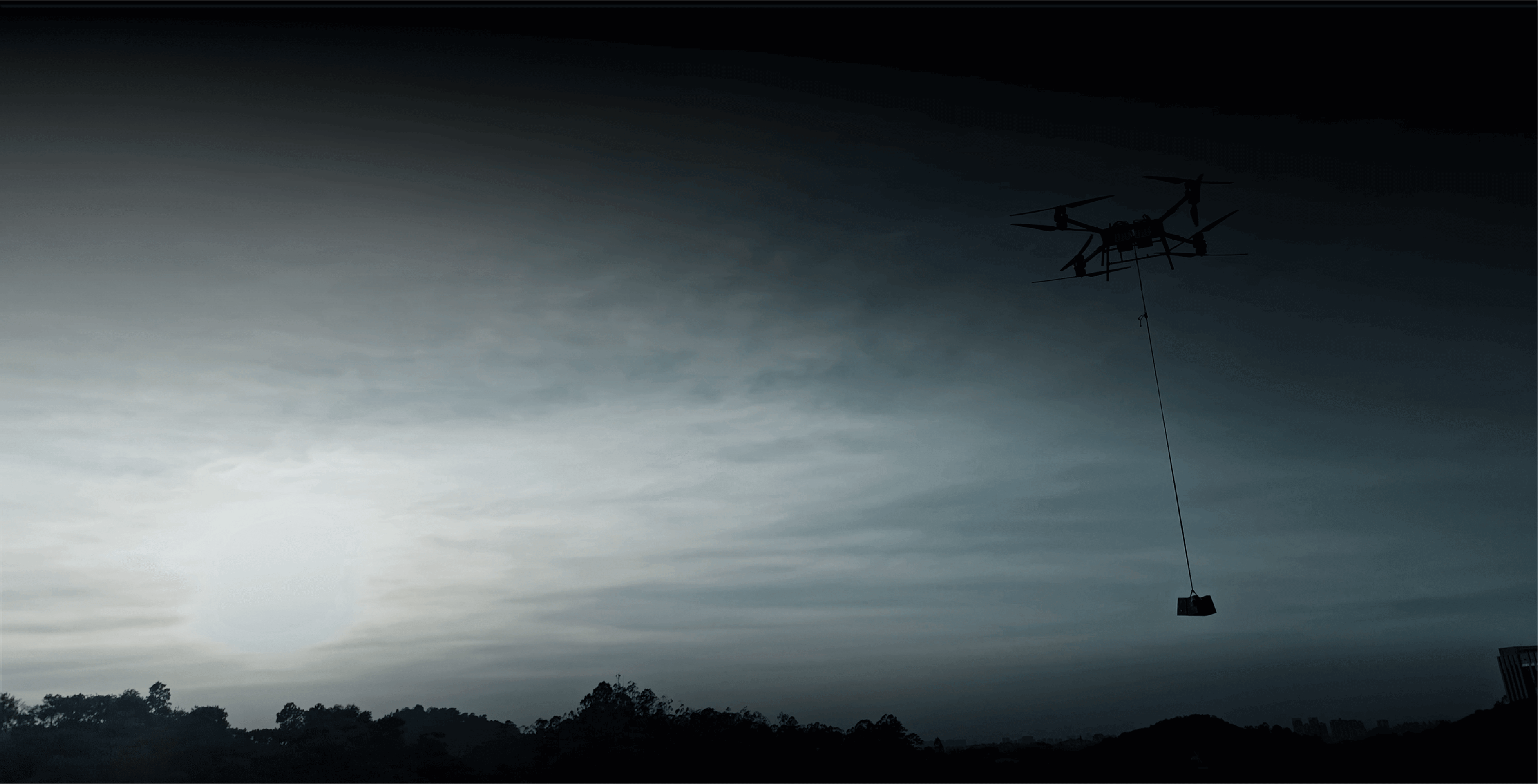

Propulsion System

with Wide Applications

- Specially designed for industrial heavy-lift UAV applications,

- this system can be applied to transportation tasks in special

- environments such as plateau and low-temperature conditions.

- Widely used in material lifting, logistics transportation,

- fire fighting, and emergency rescue applications,

- this system meets a wide array of task requirements.

- Lifting

- Logistics Transportation

- Fire Fighting

- Emergency Rescue

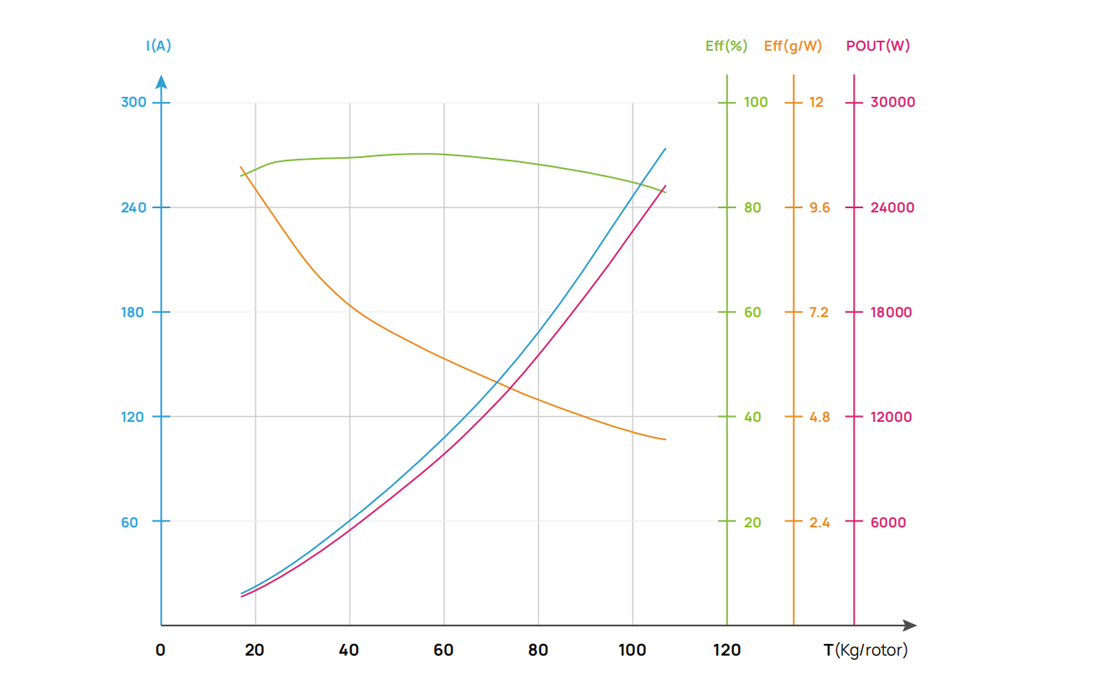

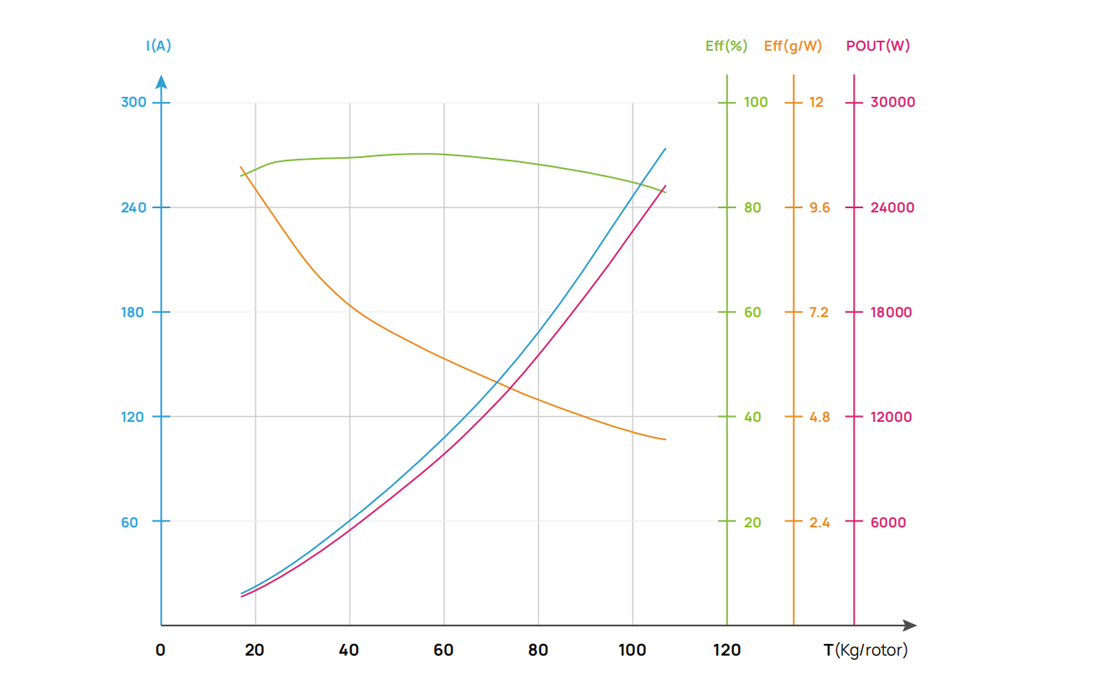

Robust Thrust, High-Pressure Stability,

and Wide Temperature Range

Rated thrust- 45kg

Max. Thrust/axis- 110kg+

- Recommened Takeff Weight

(Four-axis and Eight-propeller) - 180kg

Payload up to- 100kg

- Voltage

- 100V

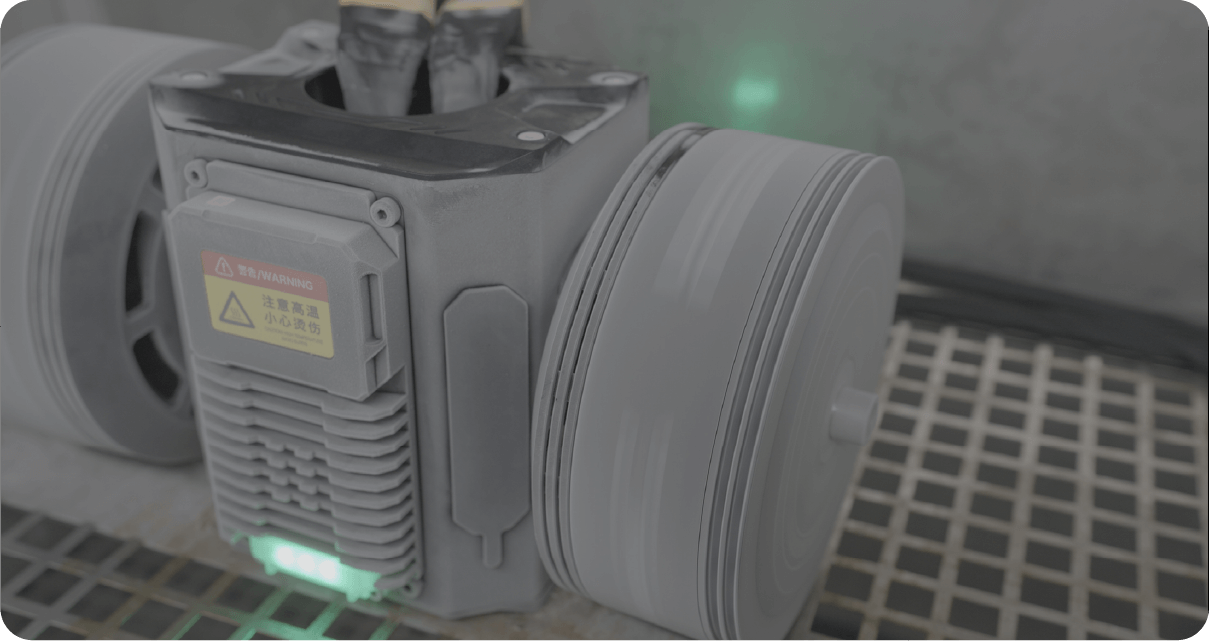

- Automotive-grade Components

- -40-65℃

- More Battery-friendly

- 28S (LiPo)

- Compared with 24S, High Voltage Brings

Lower Current and the Current Drops by - 15%

- Minimizes the Product Weight

- Smaller Wire Specification

- More Battery-friendly

- Lowers the Battery Discharge Multiplier, Improves Battery Safety, and Extends the Service Life.

with wide applications

- Specially designed for industrial heavy-lift UAV applications,

- this system can be applied to transportation tasks in special

- environments such as plateau and low-temperature conditions.

- Widely used in material lifting, logistics transportation,

- fire fighting, and emergency rescue applications,

- this system meets a wide array of task requirements.

- Material Lifting

- Logistics Transportation

- Fire Fighting

- Emergency Rescue

Robust Thrust, High-Pressure Stability,

and Wide Temperature range

- Rated thrust

- 45kg

- Max. Thrust/axis

- 110kg+

- Recommened Takeff Weight

(Four-axis and Eight-propeller) - 180kg

- Payload up to

- 100kg

- Voltage

- 100V

- Automotive-grade Components

- -40-65℃

- More Battery-friendly

- 28S (LiPo)

- Compared with 24S, High Voltage Brings

Lower Current and the Current Drops by - 15%

- Minimizes the Product Weight

- Smaller Wire Specification

- More Battery-friendly

- Lowers the Battery Discharge Multiplier, Improves Battery Safety, and Extends the Service Life.

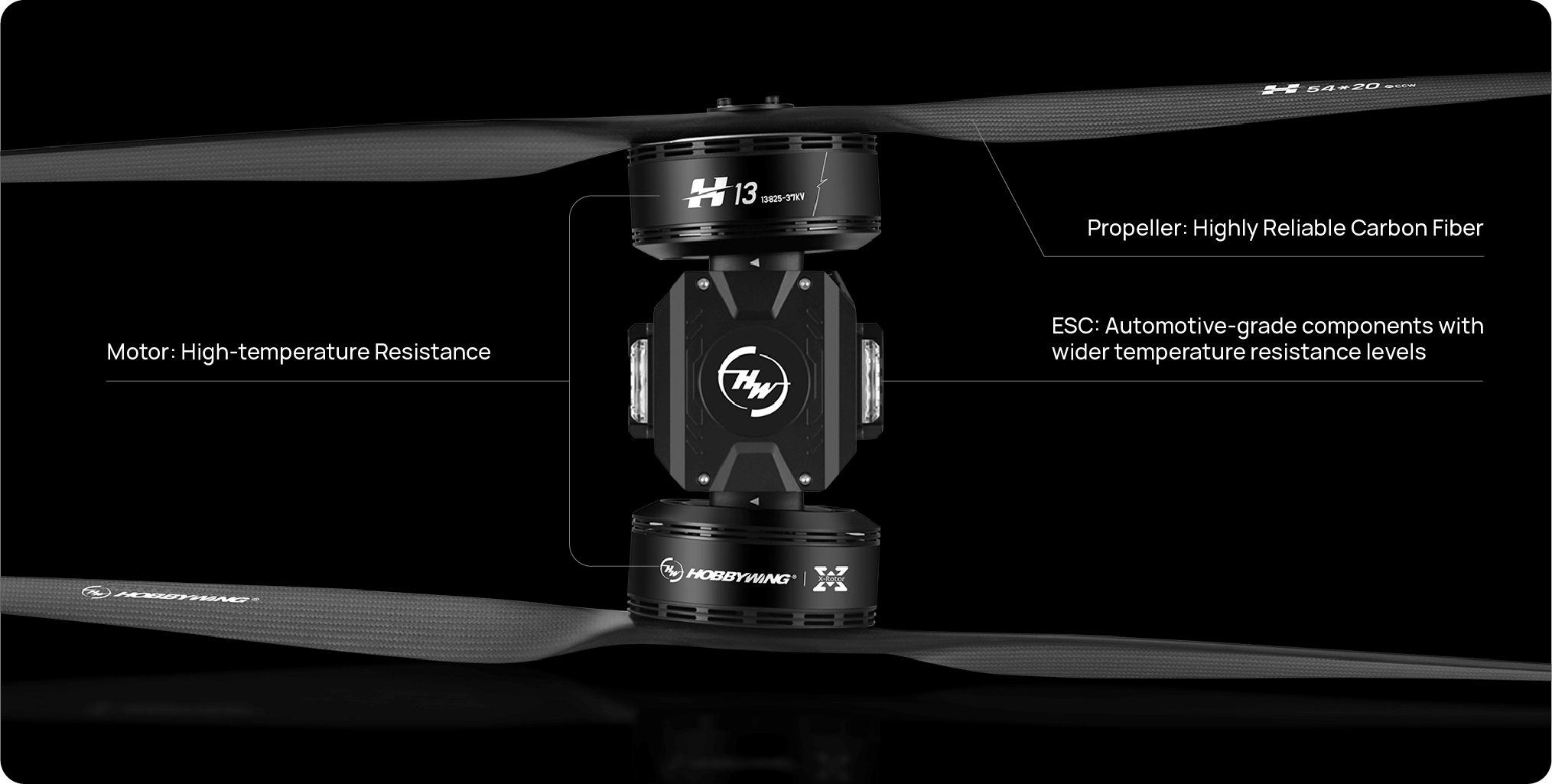

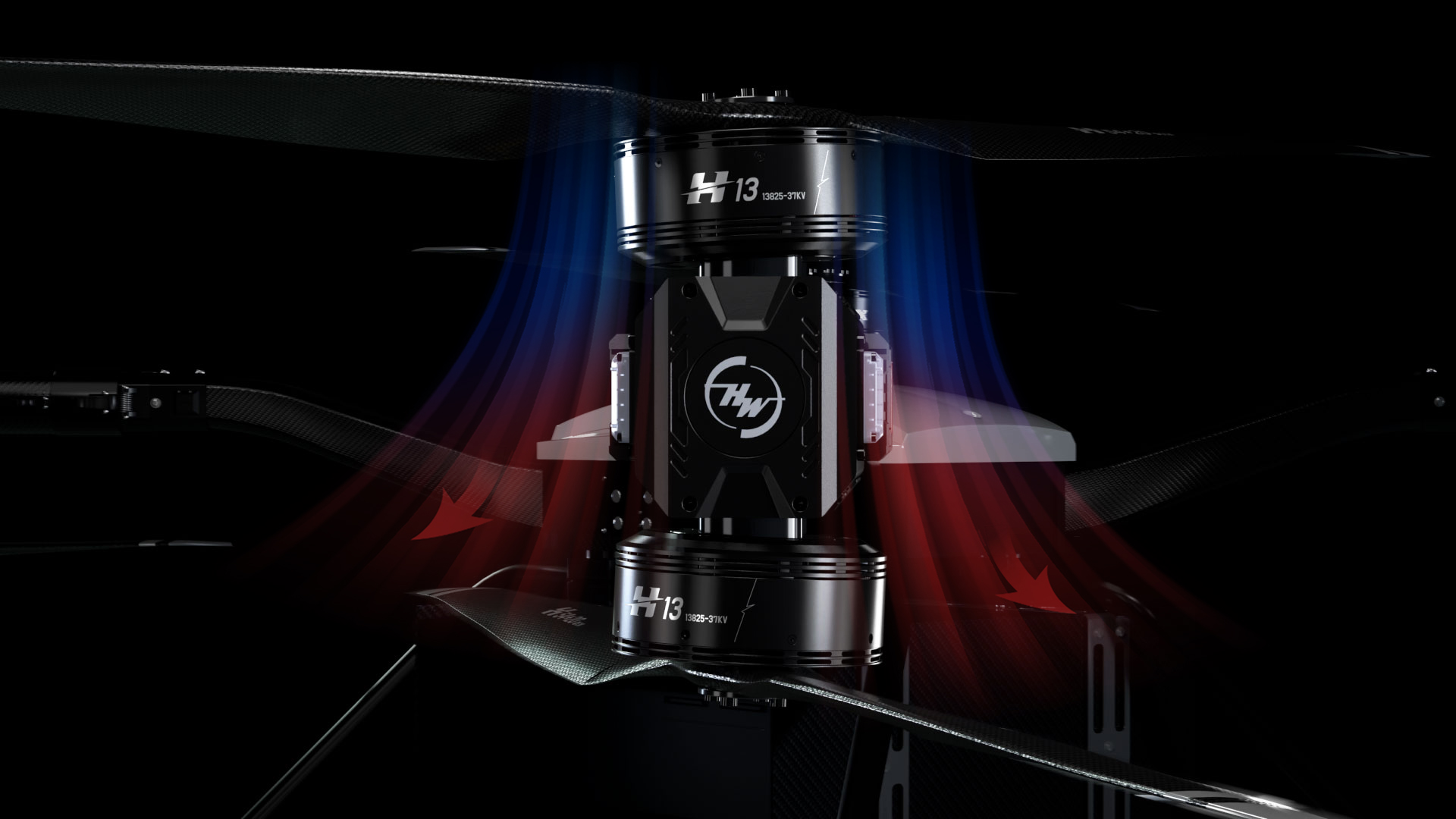

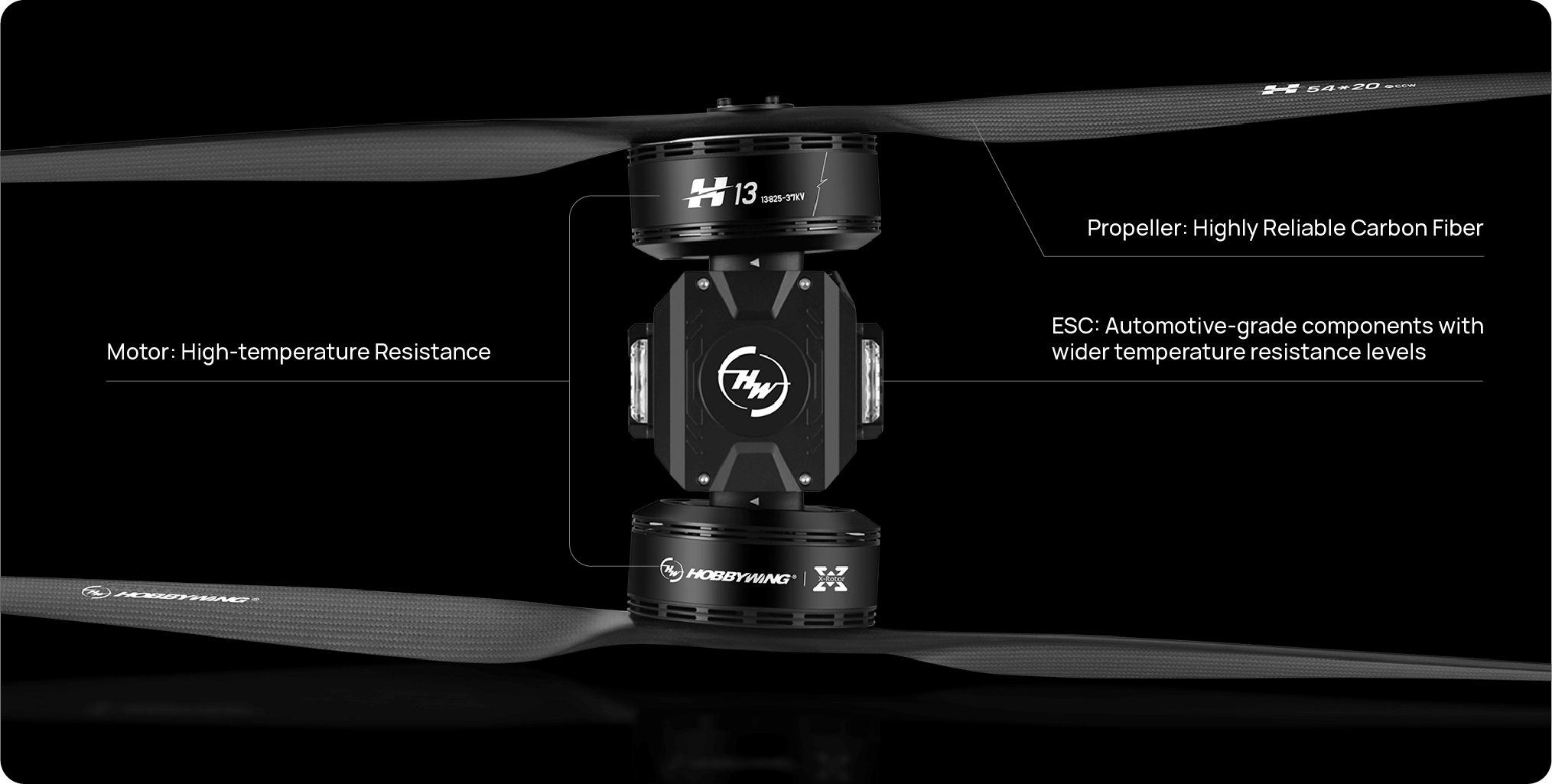

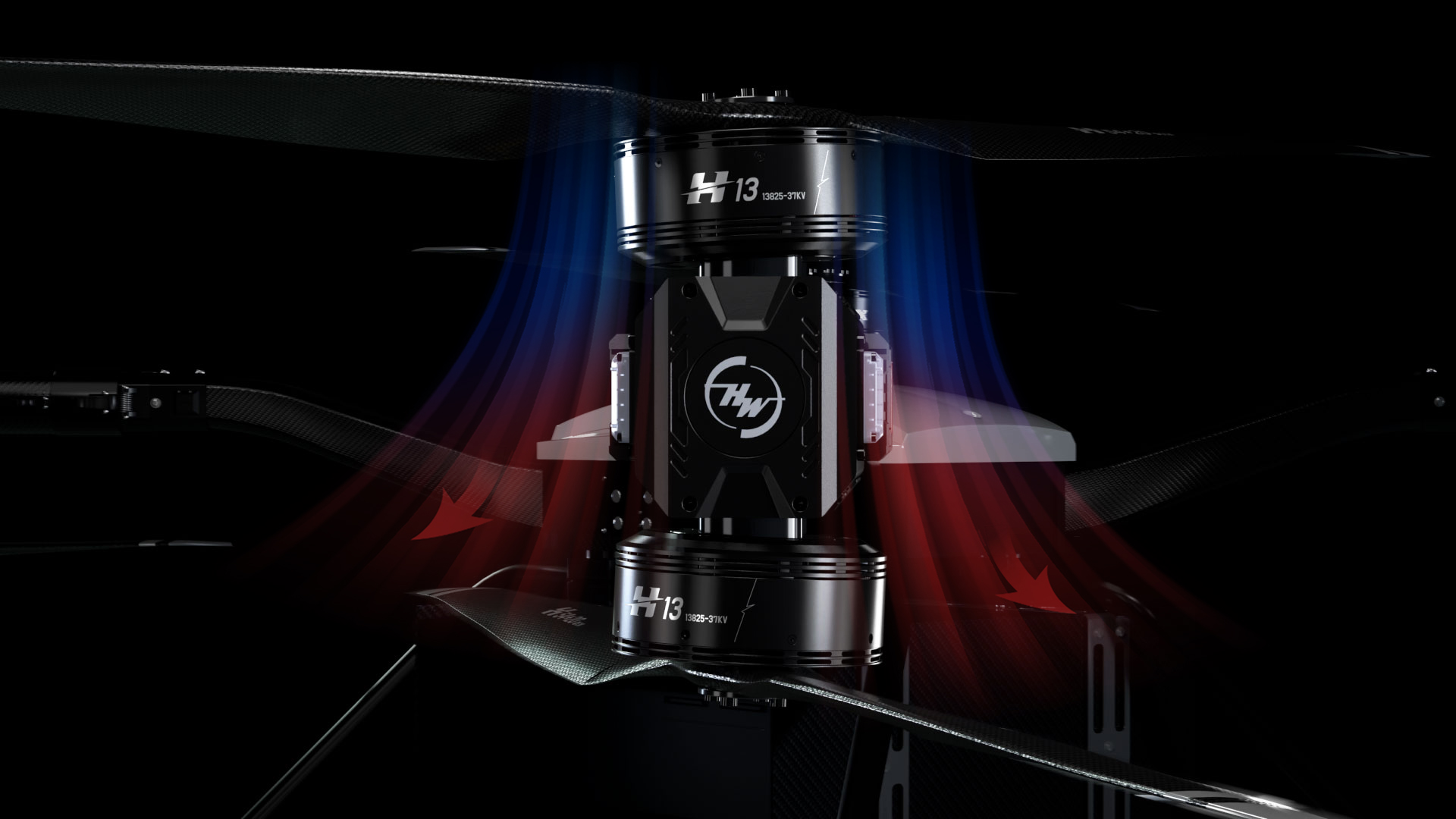

Long-Lasting Durability

- High-specification

materials - Modular design

optimization - Internal support design,

reliable locking - Tilt angle design of

the tube clip holder

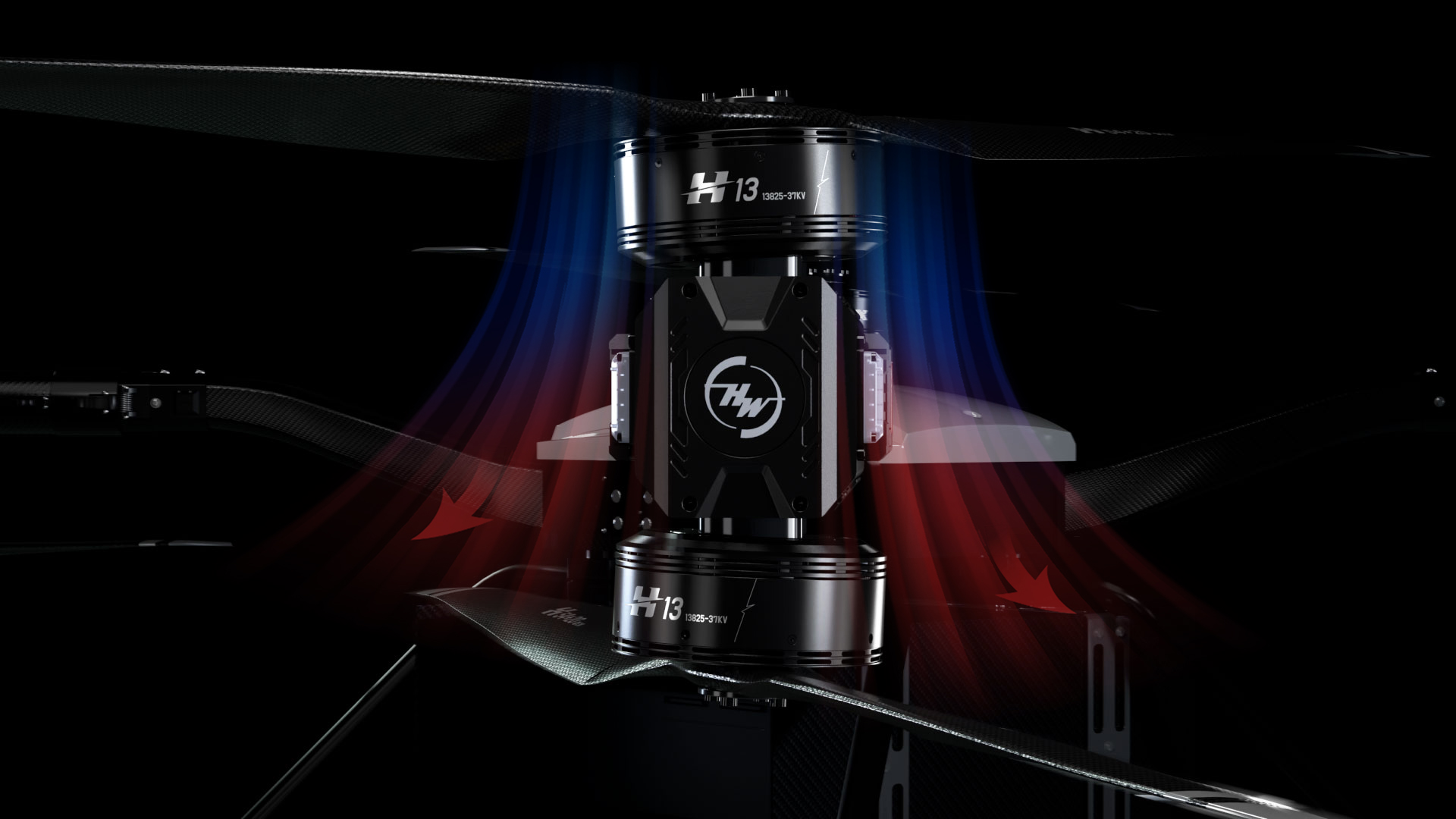

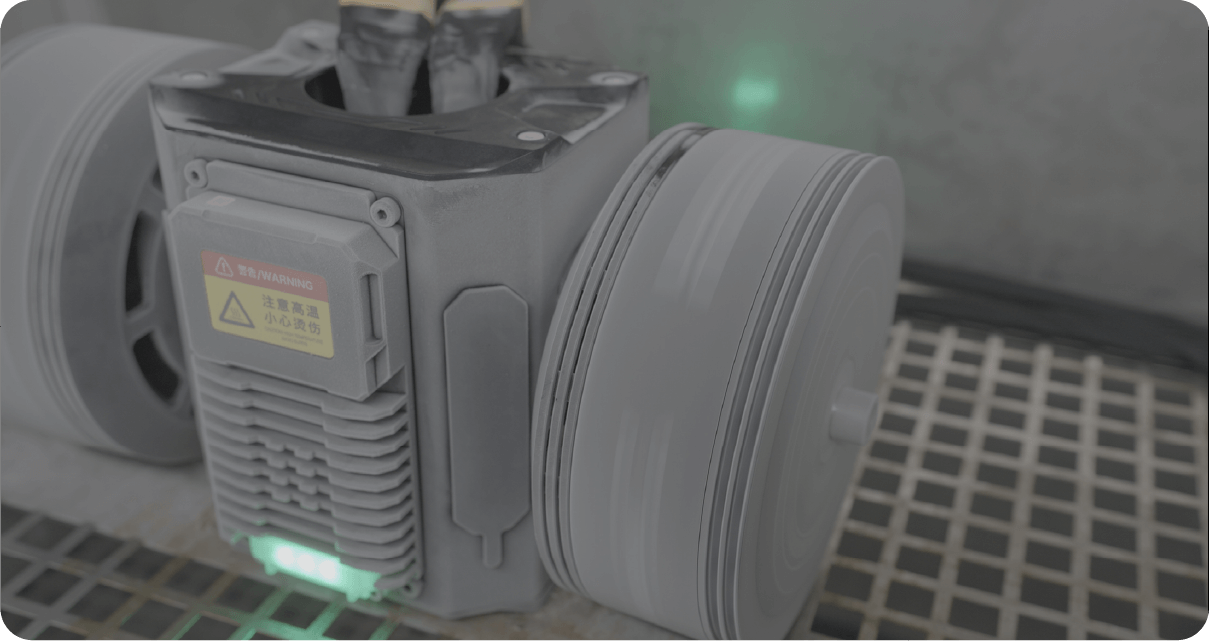

- The ESC comes with automotive-grade devices with wider temperature resistance levels.

The motor is made of high-temperature resistance materials

and the propeller adopts carbon fiber materials with higher reliability.

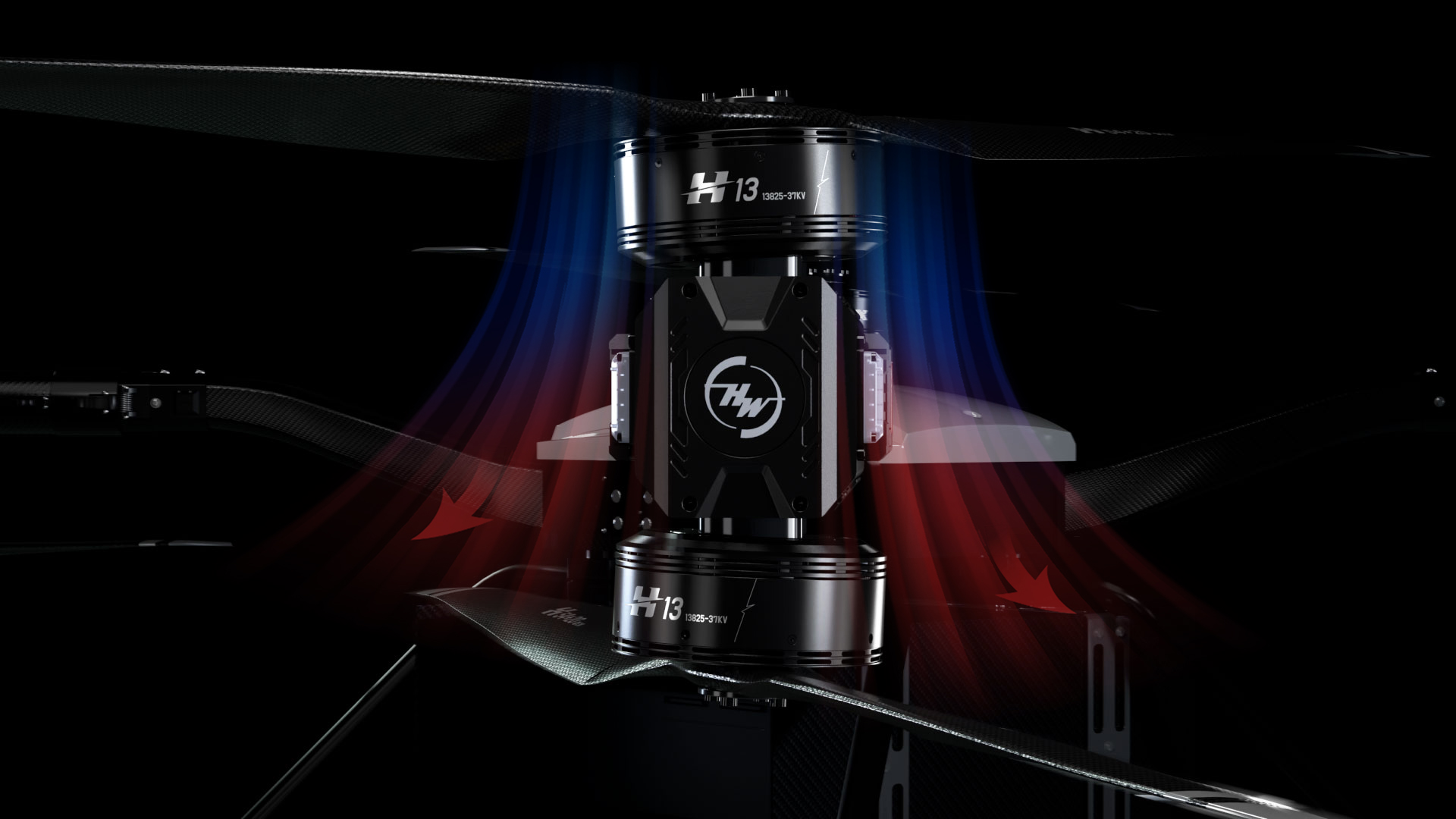

- The ESC is designed with a dual-side tube clip holder layout,

which can effectively utilize the propeller airflow for continuous heat dissipation,

easily addressing harsh heavy-lift flight tasks.

-

- The aluminum sleeve design of the carbon tube internal support allows the tube clip holder,the arm tube,

and the internal support aluminum sleeve to penetrate and

lock firmly in four directions. In addition, a positioning boss is reserved,

which can effectively prevent the propulsion system from loosening or twisting in the harsh flight vibration environment.

This ensures firm locking as well as safer and more reliable flights.

-

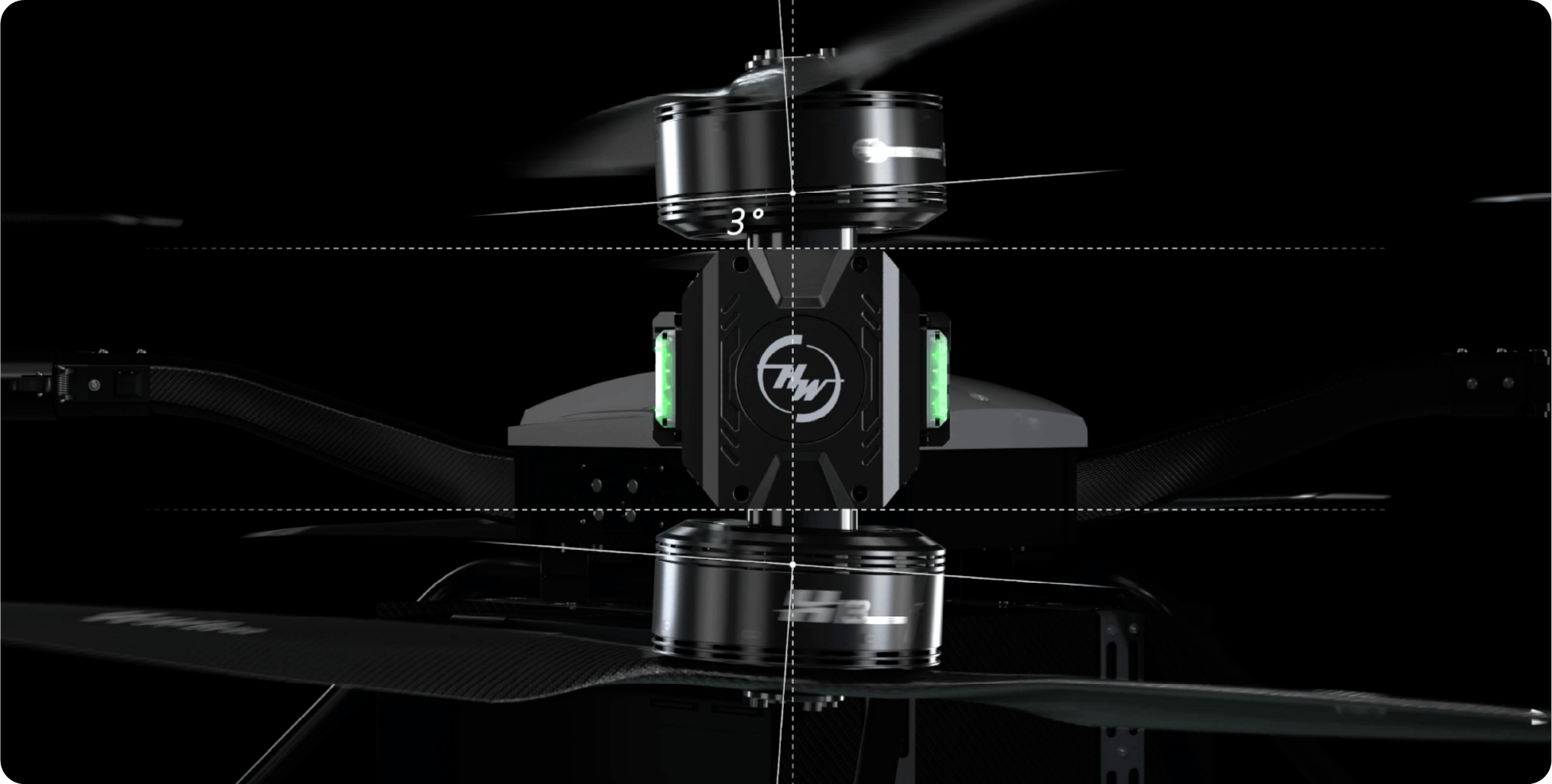

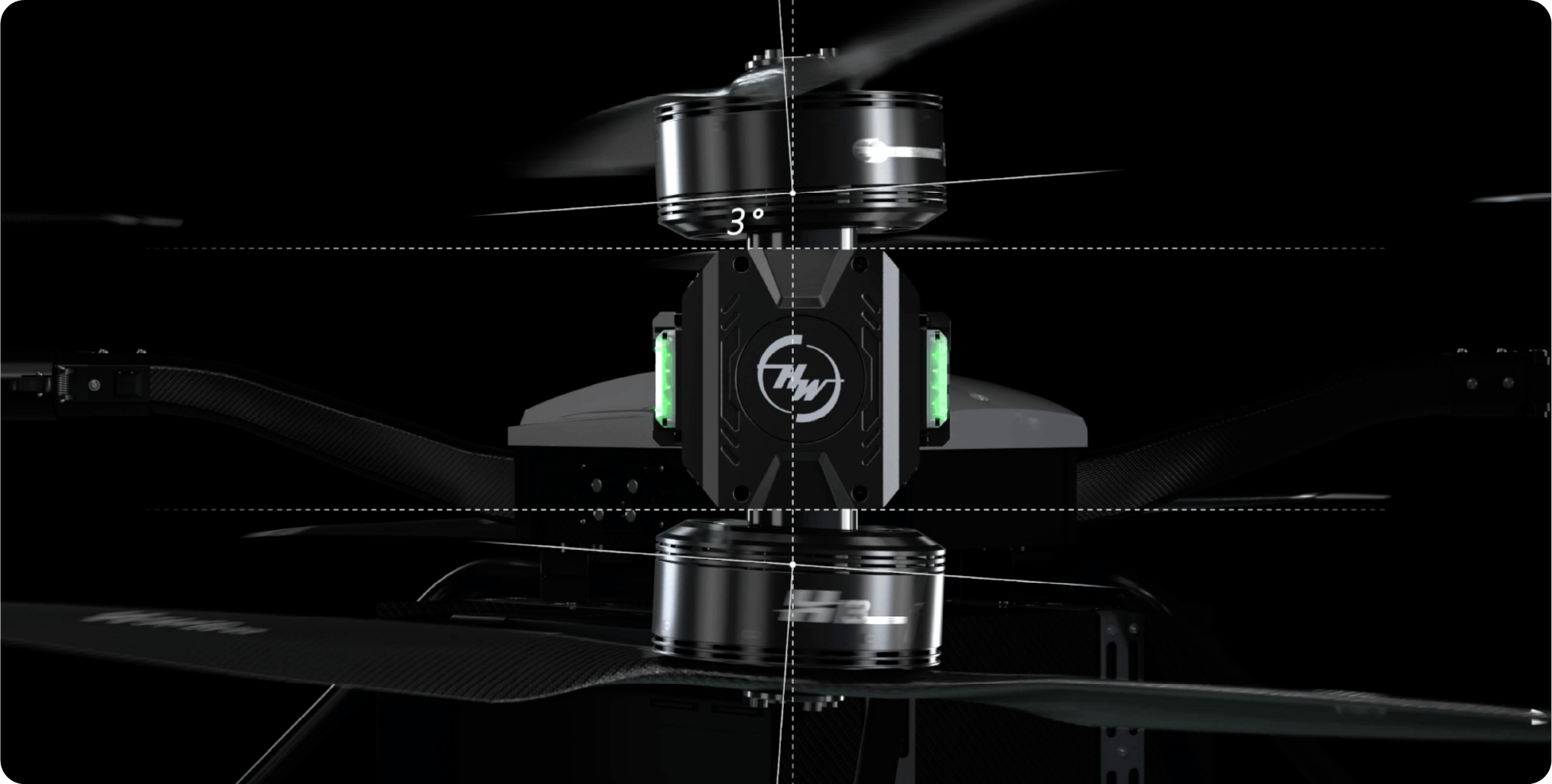

- For the characteristics of heavy-lift co-axial control,

the tube clip holder is designed with a 3-degree tilt angle,

enhancing flight control efficiency. It fits well with all kinds of flight control systems,

providing exceptional maneuverability performance and hover stability.

Long-Lasting Durability

- High-specification materials The ESC comes with automotive-grade devices with wider temperature resistance levels. The motor is made of high-temperature resistance materials and the propeller adopts carbon fiber materials with higher reliability.

- Modular design optimization The ESC is designed with a dual-side tube clip holder layout, which can effectively utilize the propeller airflow for continuous heat dissipation, easily addressing harsh heavy-lift flight tasks.

-

- Internal support design, reliable lockingThe aluminum sleeve design of the carbon tube internal support allows the tube clip holder, the arm tube, and the internal support aluminum sleeve to penetrate and lock firmly in four directions. In addition, a positioning boss is reserved, which can effectively prevent the propulsion system from loosening or twisting in the harsh flight vibration environment. This ensures firm locking as well as safer and more reliable flights.

-

- Tilt angle design of the tube clip holderFor the characteristics of heavy-lift co-axial control, the tube clip holder is designed with a 3-degree tilt angle, enhancing flight control efficiency. It fits well with all kinds of flight control systems, providing exceptional maneuverability performance and hover stability.

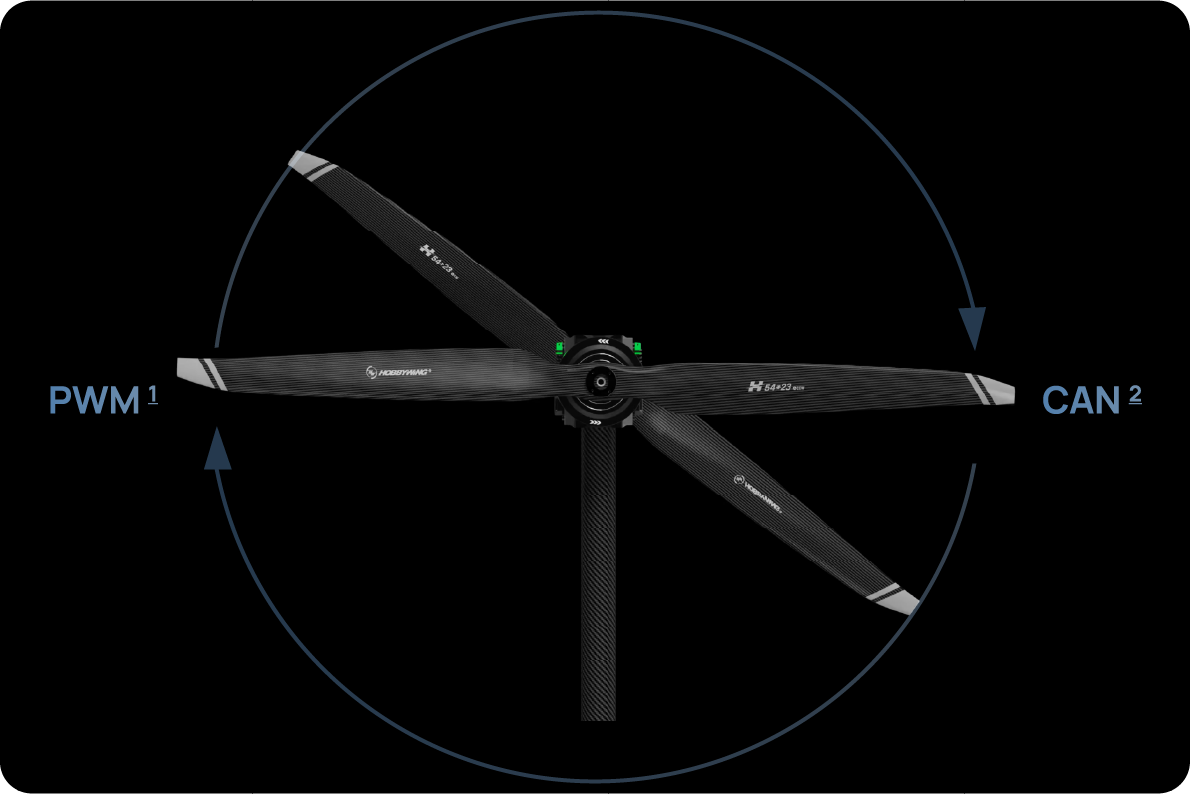

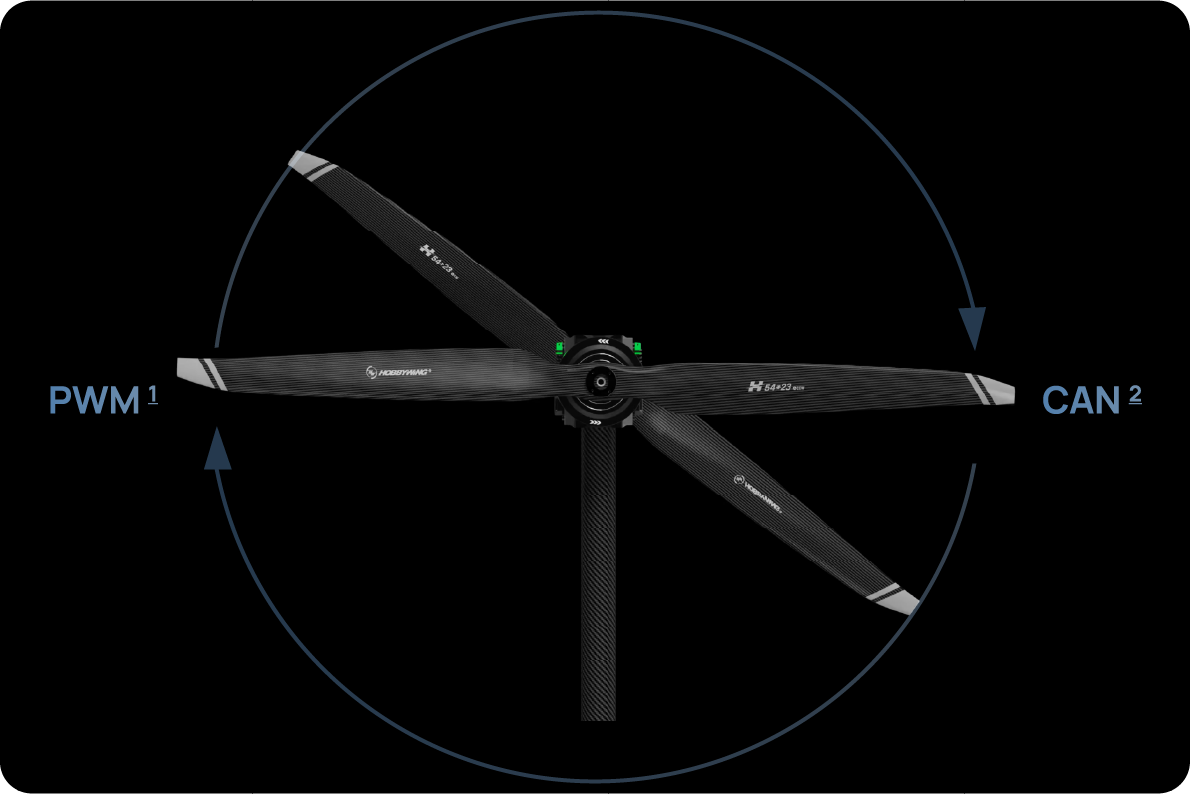

- Dual-Throttle

Redundant Control - The dual-throttle control scheme

combines CAN bus digital signals and PWM

analog signals to improve the real-time

response and anti-interference

performance of the system and ensure

flight safety.

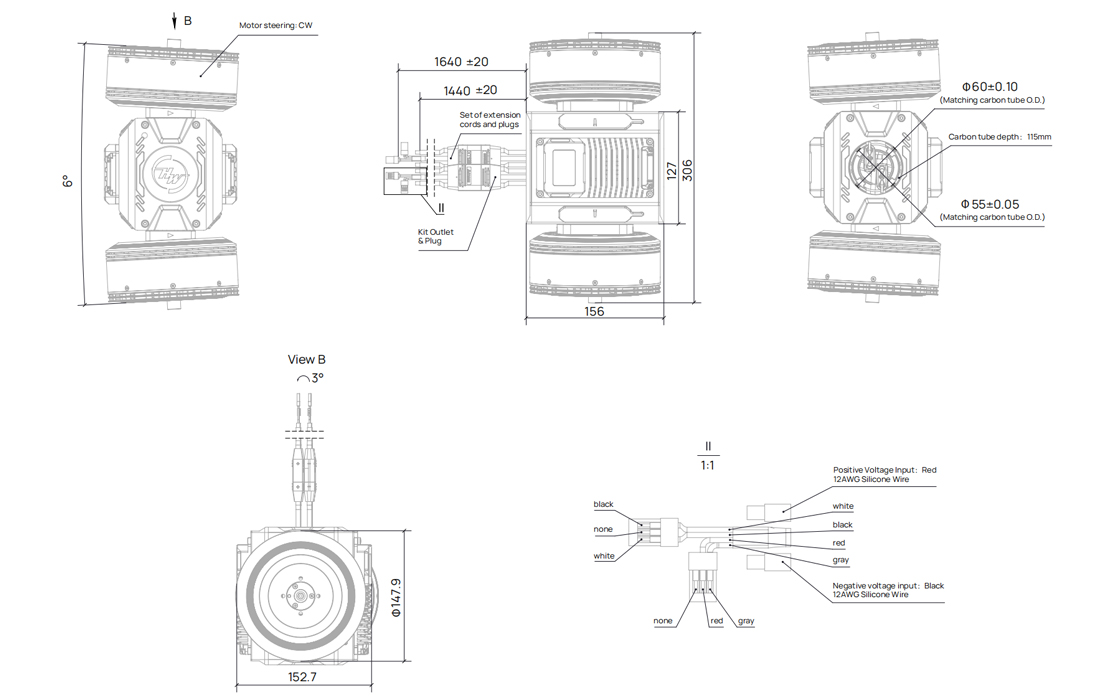

- Multi-Protection for

Safer Flight - Integrate a variety of software and

hardware protection mechanisms,

including overcurrent, stalling, throttle

loss, temperature anomaly monitoring,

and low-voltage and high-voltage

protection, ensuring comprehensive

safety for flight.

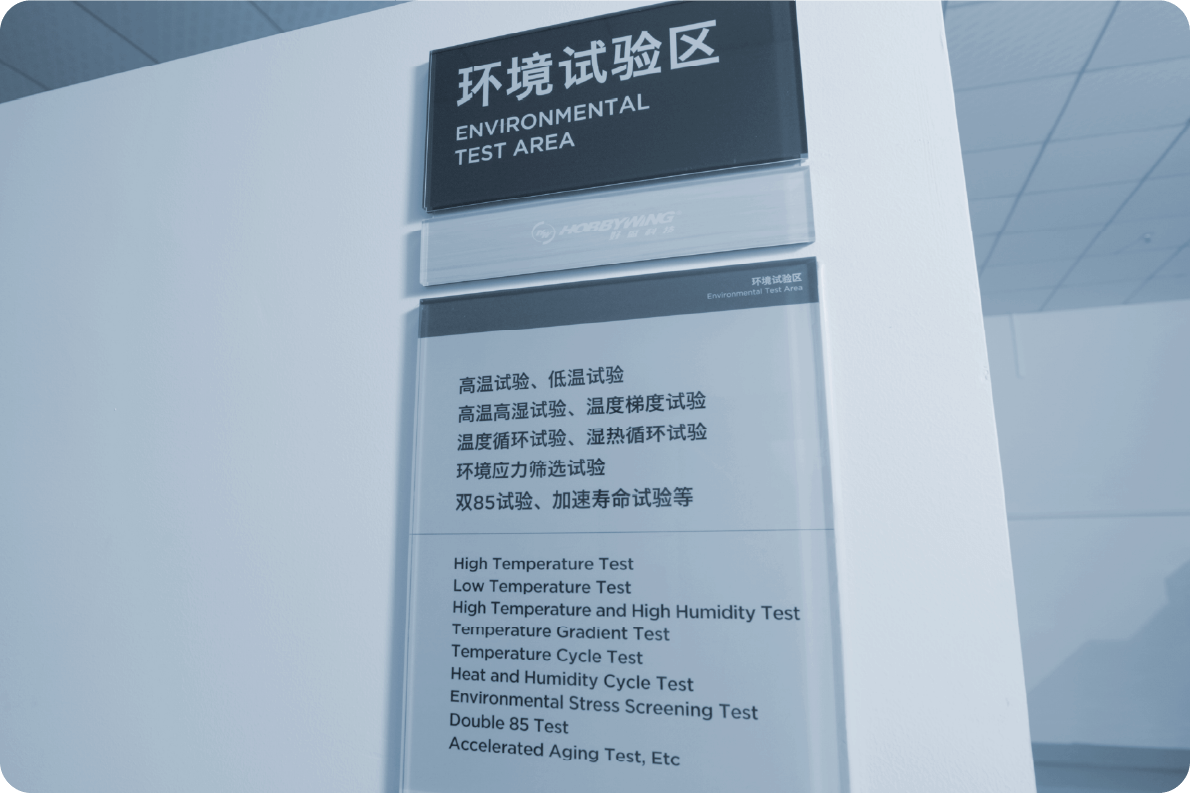

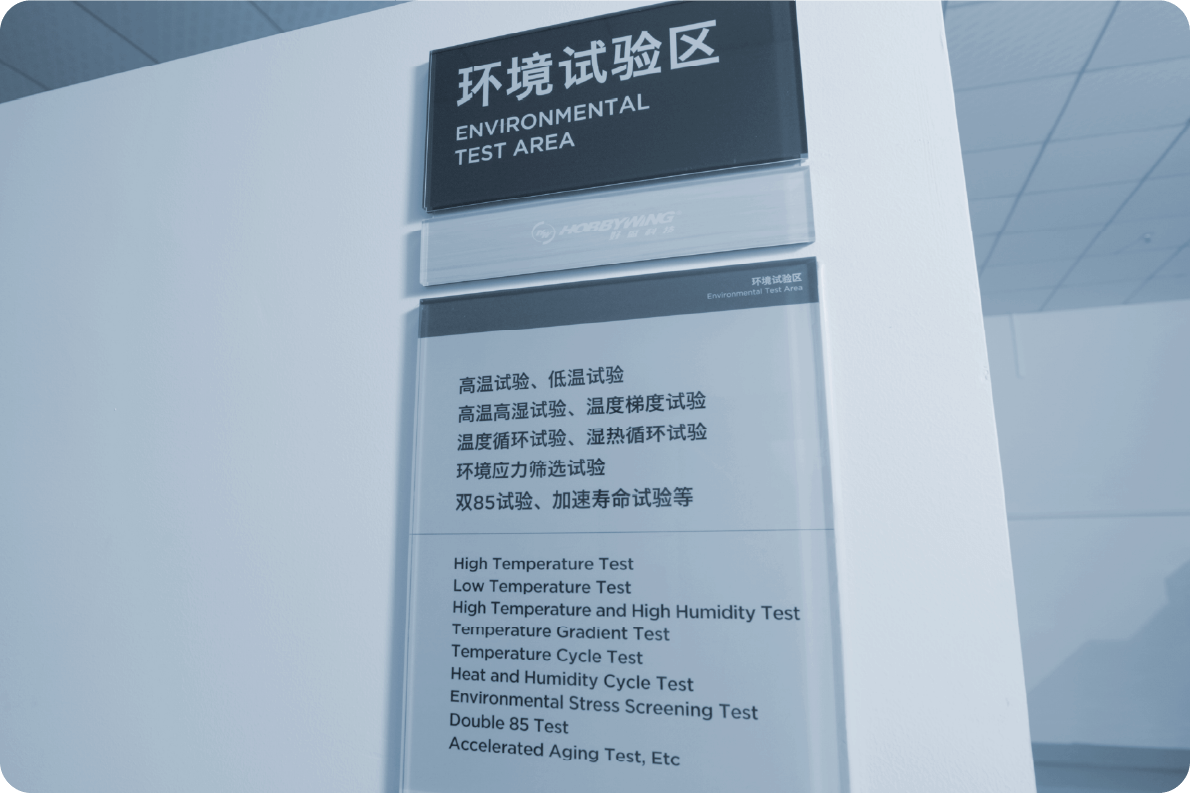

- Long-Time and

Wide-Temperature

Range Verification - This product passes through the lab life test for over 1,000 hours in the

temperature range of -40°C to 65°C and

over 500 hours of real-flight verification.

- The ESC undergoes stringent industry tests, including drive compatibility tests,

- temperature/humidity combined vibration tests, and high and low-temperature tests.

- These ensure the stable operation of the propulsion system at all times in various complex environments.

- Drive performance test

- Functional

impact test

- 0~600 Hz & 10G

vibration test

- High and low-temperature

start/stop test

- High and low-temperature

operation test

- High and low-temperature

storage test

- Temperature cycling test

- Temperature

gradient test

- Dust ingress testing

- Water ingress testing

- Thermal shock test

- Load endurance test

vibration test>

temperature test>

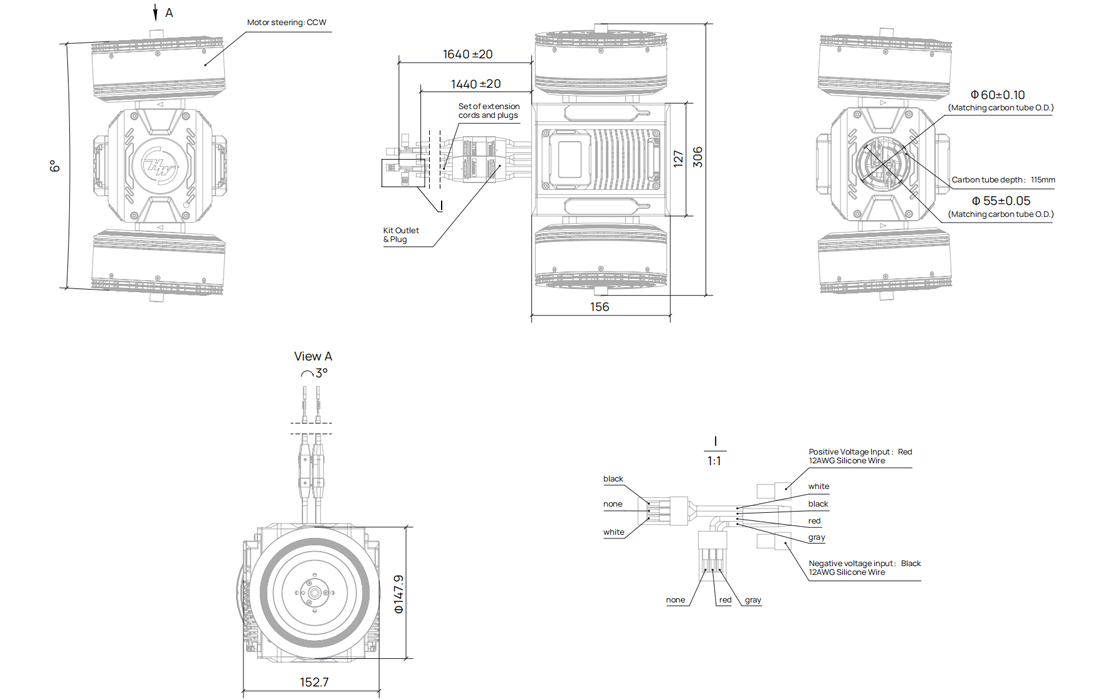

and Fully Compatible

- Well-designed and highly adaptable

- Adhering to the positive design concept of HOBBYWING, this product

- is adapted to 60mm tube diameter and 2.5mm wall thickness after

- strength analysis and reliability verification, which can be seamlessly

- integrated with the mainstream heavy-lift frames in the market.

- Convenient Installation Design

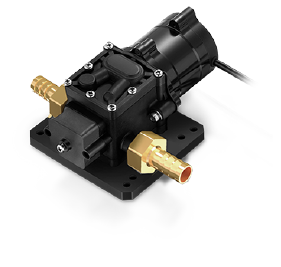

- With the high-strength aluminum alloy molded motor base, the motor is highly integrated with the ESC. The tube clip holder is designed with four-direction locking, allowing for quick installation without disassembling and assembling the motor and ESC, thus enhancing efficiency and reliability.

- Intelligent Control Fault Prompts

- Equipped with a built-in intelligent monitoring system, the device provides real-time fault status updates through an LED display, allowing for quick diagnosis.

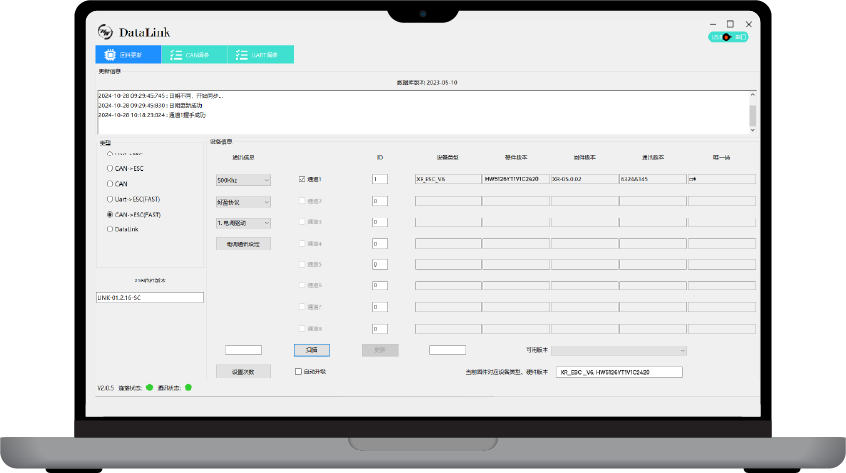

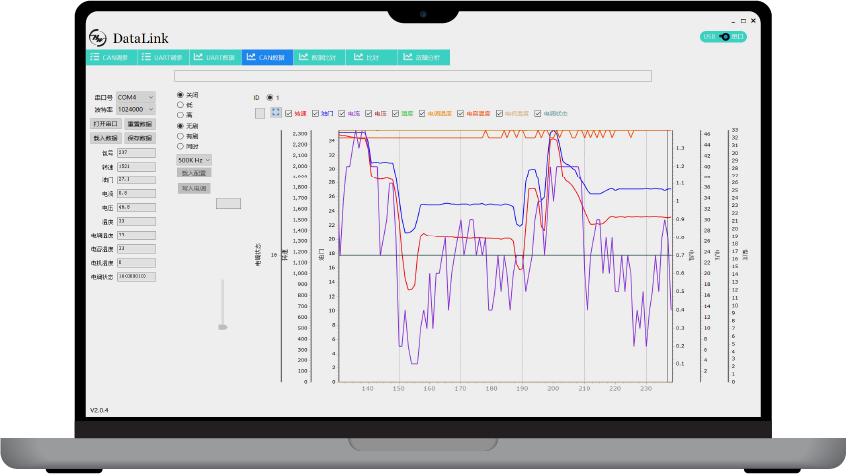

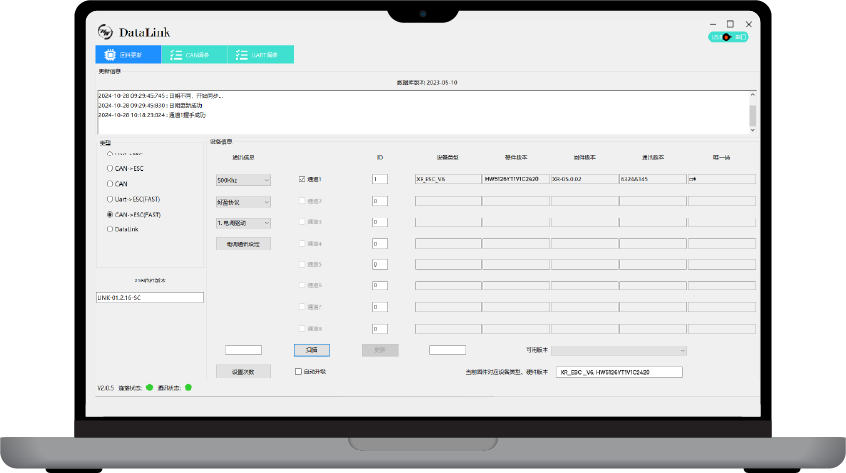

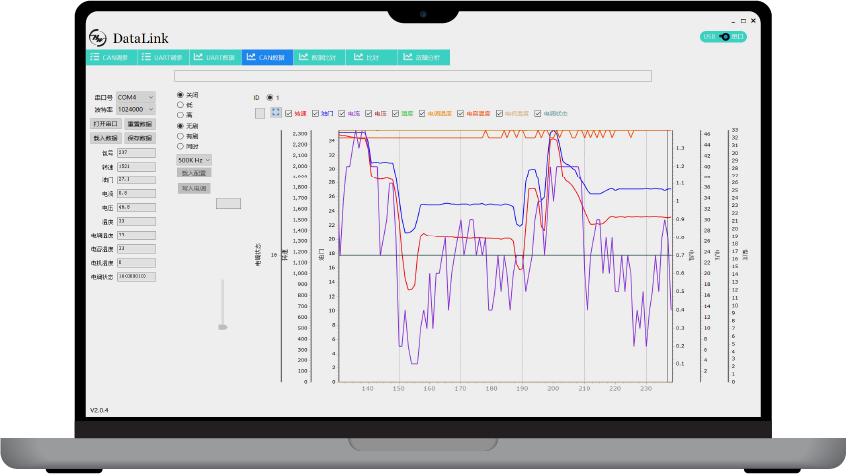

- Open Parameter Adjustment and

Firmware OTA Upgrade - With HOBBYWING’s proprietary host computer software DataLink, users can adjust drive parameters, steering, and light color effortlessly to optimize flight performance and upgrade the latest firmware.

- Wide Range of Flight Control

Compatibility - This system supports DroneCAN protocol and intercommunication with multiple mainstream flight control systems, such as ArduPilot open source ecosystem, VK, Byaero and Jiyi. It also supports CAN communication to build an intelligent flight ecosystem.

- Real-Time Data Interaction

- Real-time data interaction with the flight control system is made available via the CAN interface for monitoring key flight parameters, such as speed, throttle, current, voltage and temperature. This allows for fast data analysis and timely response while enhancing safety.

- Independent Black Box

- The built-in black box of the ESC automatically stores real-time operation data and fault codes of the propulsion system for quick location and diagnosis of faults.

Storage of Propellers

- Specially designed for H13, this quick-assembly propeller mounting base is compatible with 57x20" and 54x20" installation holes

- It eliminates the hassle of large propeller assembly, making storage and transportation more space-efficient and effective.

- "No need for threadlocker" "Tighten the nut securely"

Service

- 1 Customizable extension cables of different

sizes and lengths; - 2 Customizable tilt adapters of the tube clip

holder with different angles; - 3Customizable motor temperature monitoring

and propeller locking function; - 4Optional carbon fiber straight propellers or

folding propellers as needed.

Configuration

- Takeoff weight

- 180kg

- Rated thrust

- 45kg

- Recommended payload

- 100kg

- Endurance

- 20min+

- Recommended battery

- 24S 70000mAh*2

- Flight Time

- 20min+

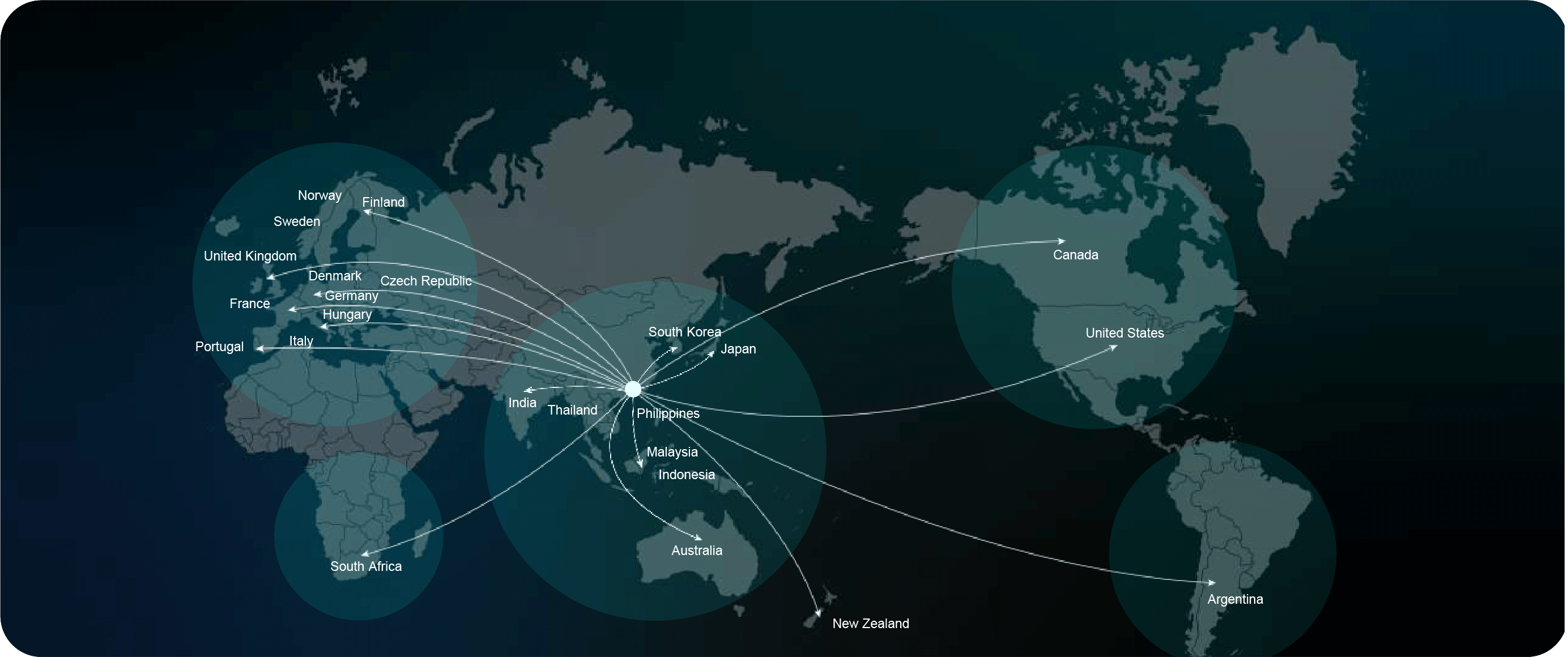

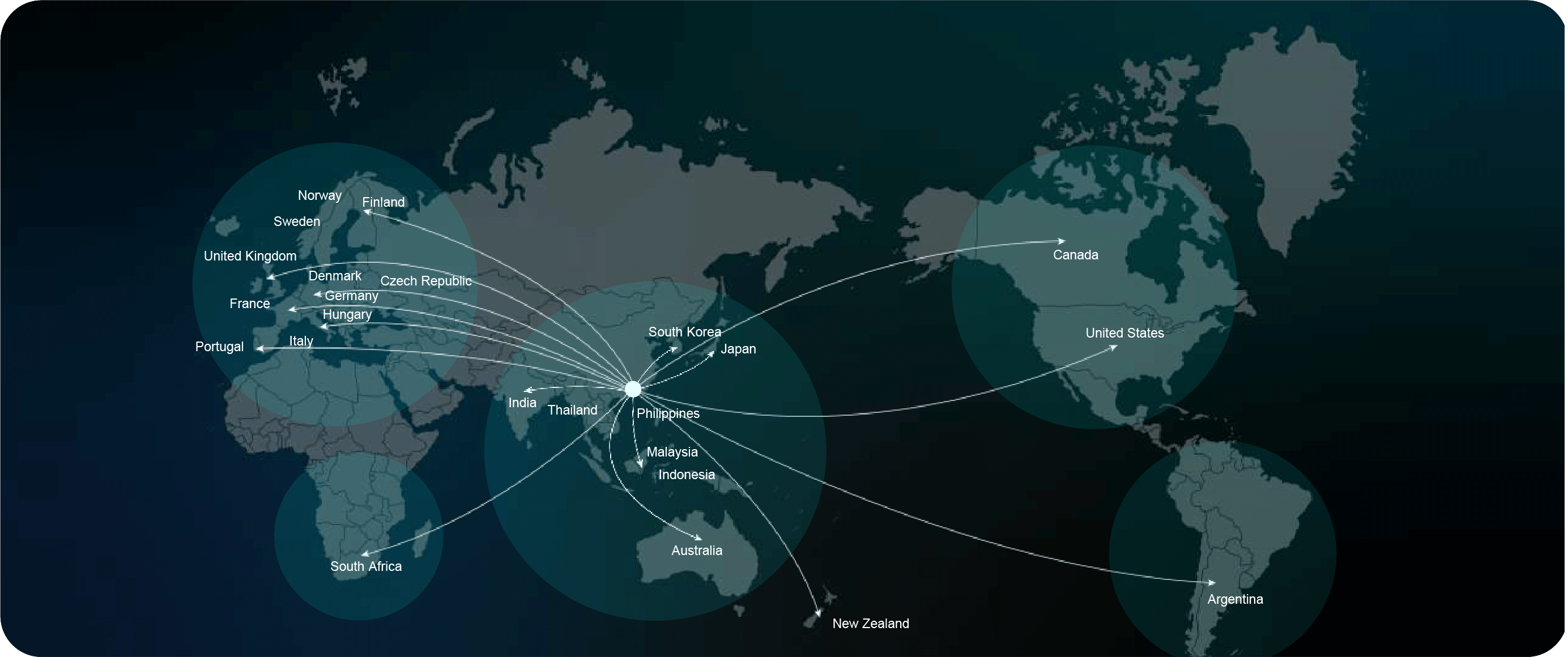

- HOBBYWING is one of the world’s earliest professional manufacturers of UAV motors and ESCs,

- serving over 500 UAV manufacturers. The UAV propulsion systems produced have an accumulative flight time of 50 million hours.

- Flight Time

- 5000W+Hours

- Serving

- 500+UAV Manufacturers

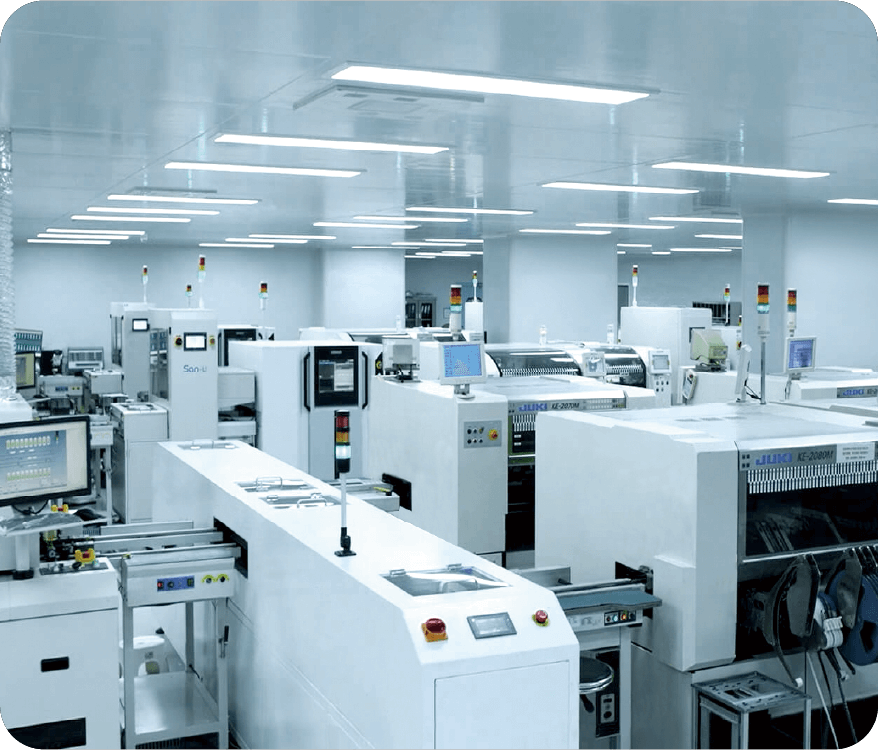

- Full Manufacturing Chain

Advantages - The complete manufacturing chain of SMT, precision machining, precision injection molding, automated wire making, and automated assembly strongly guarantee the high quality level of products from design to manufacturing.

- Pre-Sales Technical Support

- Our dedicated FAE team provides pre-sales consultation to ensure that users receive the most suitable UAV propulsion products and customized solutions.

- After-Sales Professional Maintenance

- Our professional after-sales maintenance team promises to provide users with rapid and efficient maintenance services to safeguard their interests.

- Mature Sales Channels

- With two decades of experience, worldwide sales channels are established,

ensuring that our products and services are easily accessible to customers.

-

-

Thank you for your interest in HOBBYWING propulsion systems! For customized solutions,

please provide your contact information and technical requirements,

and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

| Product Name |

|

||||||||||||||||||||||||||||||||||||||||||

| Specifications |

|

||||||||||||||||||||||||||||||||||||||||||

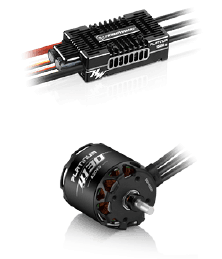

| Motor |

|

||||||||||||||||||||||||||||||||||||||||||

| ESC |

|

||||||||||||||||||||||||||||||||||||||||||

| Propeller |

|

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

108V (28S LiPo) |

MSC 54x20 |

33% |

17914 |

16.2 |

1746 |

85.8 |

10.3 |

80℃ |

|

35% |

18957 |

17.4 |

1883 |

86.2 |

10.1 |

|||

|

37% |

21158 |

20.2 |

2178 |

87.1 |

9.7 |

|||

|

39% |

23491 |

23.2 |

2510 |

87.9 |

9.4 |

|||

|

41% |

25937 |

26.7 |

2885 |

88.5 |

9.0 |

|||

|

43% |

28482 |

30.6 |

3303 |

88.9 |

8.6 |

|||

|

45% |

31114 |

34.8 |

3762 |

89.1 |

8.3 |

|||

|

46% |

32460 |

37.1 |

4006 |

89.2 |

8.1 |

|||

|

48% |

35211 |

41.8 |

4520 |

89.3 |

7.8 |

|||

|

51% |

39477 |

49.6 |

5353 |

89.5 |

7.4 |

|||

|

53% |

42414 |

55.1 |

5947 |

89.6 |

7.1 |

|||

|

55% |

45426 |

60.8 |

6573 |

89.7 |

6.9 |

|||

|

58% |

50091 |

70.1 |

7573 |

89.8v |

6.6 |

|||

|

61% |

54935 |

80.2 |

8659 |

89.8 |

6.3 |

|||

|

63% |

58266 |

87.4 |

9439 |

89.7 |

6.2 |

|||

|

65% |

61676 |

95.1 |

10270 |

89.6 |

6.0 |

|||

|

68% |

66931 |

107.6 |

11623 |

89.3 |

5.8 |

|||

|

71% |

72332 |

121.4 |

13115 |

88.8 |

5.5 |

|||

|

75% |

79680 |

141.8 |

15320 |

88.0 |

5.2 |

|||

|

80% |

88845 |

169.9 |

18358 |

86.7 |

4.8 |

|||

|

85% |

97474 |

198.9 |

21491 |

85.1 |

4.5 |

|||

|

100% |

110511 |

245.8 |

26556 |

81.7 |

4.2 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

92V (24S LiPo) |

MSC 57x20 |

33% |

20407 |

21.6 |

1988 |

86 |

10.3 |

84℃ |

|

35% |

21552 |

23.1 |

2125 |

87 |

10.1 |

|||

|

37% |

23988 |

26.4 |

2434 |

88 |

9.9 |

|||

|

39% |

26580 |

30.4 |

2801 |

89 |

9.5 |

|||

|

41% |

29291 |

35.1 |

3230 |

89 |

9.1 |

|||

|

43% |

32092 |

40.4 |

3714 |

89 |

8.6 |

|||

|

45% |

34965 |

46.1 |

4246 |

89 |

8.2 |

|||

|

47% |

37896 |

52.3 |

4814 |

88 |

7.9 |

|||

|

49% |

40877 |

58.8 |

5410 |

88 |

7.6 |

|||

|

51% |

43907 |

65.5 |

6027 |

88 |

7.3 |

|||

|

52% |

45440 |

68.9 |

6343 |

88 |

7.2 |

|||

|

53% |

46986 |

72.4 |

6663 |

88 |

7.1 |

|||

|

56% |

51708 |

83.1 |

7652 |

89 |

6.8 |

|||

|

59% |

56572 |

94.6 |

8703 |

89 |

6.5 |

|||

|

62% |

61603 |

107.0 |

9847 |

89 |

6.3 |

|||

|

65% |

66816 |

120.9 |

11122 |

89 |

6.0 |

|||

|

68% |

72217 |

136.5 |

12560 |

88 |

5.7 |

|||

|

71% |

77787 |

154.1 |

14181 |

87 |

5.5 |

|||

|

75% |

85394 |

180.5 |

16614 |

86 |

5.1 |

|||

|

80% |

94870 |

216.5 |

19928 |

84 |

4.8 |

|||

|

85% |

103599 |

251.2 |

23117 |

82 |

4.5 |

|||

|

100% |

112566 |

284.5 |

26185 |

80 |

4.3 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

108V (28S LiPo) |

MSC 57x20 |

33% |

21109 |

19.6 |

2115 |

86 |

10.0 |

79℃ |

|

35% |

22328 |

20.8 |

2249 |

87 |

9.9 |

|||

|

37% |

24898 |

23.9 |

2581 |

88 |

9.6 |

|||

|

39% |

27613 |

27.7 |

2990 |

88 |

9.2 |

|||

|

41% |

30447 |

32.1 |

3464 |

88 |

8.8 |

|||

|

43% |

33376 |

36.9 |

3991 |

88 |

8.4 |

|||

|

45% |

36386 |

42.2 |

4558 |

88 |

8.0 |

|||

|

47% |

39466 |

47.7 |

5156 |

88 |

7.7 |

|||

|

49% |

42610 |

53.5 |

5780 |

88 |

7.4 |

|||

|

50% |

44205 |

56.5 |

6101 |

88 |

7.2 |

|||

|

51% |

45815 |

59.5 |

6428 |

88 |

7.1 |

|||

|

52% |

47440 |

62.6 |

6760 |

88 |

7.0 |

|||

|

55% |

52407 |

72.2 |

7796 |

88 |

6.7 |

|||

|

57% |

55799 |

78.9 |

8527 |

89 |

6.5 |

|||

|

60% |

61013 |

89.8 |

9702 |

89 |

6.3 |

|||

|

65% |

70049 |

110.6 |

11945 |

88 |

5.9 |

|||

|

68% |

75659 |

124.9 |

13494 |

88 |

5.6 |

|||

|

71% |

81373 |

140.7 |

15203 |

87 |

5.4 |

|||

|

75% |

89035 |

163.7 |

17687 |

85 |

5.0 |

|||

|

80% |

98321 |

193.7 |

20928 |

84 |

4.7 |

|||

|

85% |

106542 |

221.2 |

23893 |

82 |

4.5 |

|||

|

100% |

113038 |

243.3 |

26282 |

80 |

4 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.

Propulsion System

with Wide Applications

- Specially designed for industrial heavy-lift UAV applications,

- this system can be applied to transportation tasks in special

- environments such as plateau and low-temperature conditions.

- Widely used in material lifting, logistics transportation,

- fire fighting, and emergency rescue applications,

- this system meets a wide array of task requirements.

- Lifting

- Logistics Transportation

- Fire Fighting

- Emergency Rescue

Robust Thrust, High-Pressure Stability,

and Wide Temperature Range

Rated thrust- 45kg

Max. Thrust/axis- 110kg+

- Recommened Takeff Weight

(Four-axis and Eight-propeller) - 180kg

Payload up to- 100kg

- Voltage

- 100V

- Automotive-grade Components

- -40-65℃

- More Battery-friendly

- 28S (LiPo)

- Compared with 24S, High Voltage Brings

Lower Current and the Current Drops by - 15%

- Minimizes the Product Weight

- Smaller Wire Specification

- More Battery-friendly

- Lowers the Battery Discharge Multiplier, Improves Battery Safety, and Extends the Service Life.

with wide applications

- Specially designed for industrial heavy-lift UAV applications,

- this system can be applied to transportation tasks in special

- environments such as plateau and low-temperature conditions.

- Widely used in material lifting, logistics transportation,

- fire fighting, and emergency rescue applications,

- this system meets a wide array of task requirements.

- Material Lifting

- Logistics Transportation

- Fire Fighting

- Emergency Rescue

Robust Thrust, High-Pressure Stability,

and Wide Temperature range

- Rated thrust

- 45kg

- Max. Thrust/axis

- 110kg+

- Recommened Takeff Weight

(Four-axis and Eight-propeller) - 180kg

- Payload up to

- 100kg

- Voltage

- 100V

- Automotive-grade Components

- -40-65℃

- More Battery-friendly

- 28S (LiPo)

- Compared with 24S, High Voltage Brings

Lower Current and the Current Drops by - 15%

- Minimizes the Product Weight

- Smaller Wire Specification

- More Battery-friendly

- Lowers the Battery Discharge Multiplier, Improves Battery Safety, and Extends the Service Life.

Long-Lasting Durability

- High-specification

materials - Modular design

optimization - Internal support design,

reliable locking - Tilt angle design of

the tube clip holder

- The ESC comes with automotive-grade devices with wider temperature resistance levels.

The motor is made of high-temperature resistance materials

and the propeller adopts carbon fiber materials with higher reliability.

- The ESC is designed with a dual-side tube clip holder layout,

which can effectively utilize the propeller airflow for continuous heat dissipation,

easily addressing harsh heavy-lift flight tasks.

-

- The aluminum sleeve design of the carbon tube internal support allows the tube clip holder,the arm tube,

and the internal support aluminum sleeve to penetrate and

lock firmly in four directions. In addition, a positioning boss is reserved,

which can effectively prevent the propulsion system from loosening or twisting in the harsh flight vibration environment.

This ensures firm locking as well as safer and more reliable flights.

-

- For the characteristics of heavy-lift co-axial control,

the tube clip holder is designed with a 3-degree tilt angle,

enhancing flight control efficiency. It fits well with all kinds of flight control systems,

providing exceptional maneuverability performance and hover stability.

Long-Lasting Durability

- High-specification materials The ESC comes with automotive-grade devices with wider temperature resistance levels. The motor is made of high-temperature resistance materials and the propeller adopts carbon fiber materials with higher reliability.

- Modular design optimization The ESC is designed with a dual-side tube clip holder layout, which can effectively utilize the propeller airflow for continuous heat dissipation, easily addressing harsh heavy-lift flight tasks.

-

- Internal support design, reliable lockingThe aluminum sleeve design of the carbon tube internal support allows the tube clip holder, the arm tube, and the internal support aluminum sleeve to penetrate and lock firmly in four directions. In addition, a positioning boss is reserved, which can effectively prevent the propulsion system from loosening or twisting in the harsh flight vibration environment. This ensures firm locking as well as safer and more reliable flights.

-

- Tilt angle design of the tube clip holderFor the characteristics of heavy-lift co-axial control, the tube clip holder is designed with a 3-degree tilt angle, enhancing flight control efficiency. It fits well with all kinds of flight control systems, providing exceptional maneuverability performance and hover stability.

- Dual-Throttle

Redundant Control - The dual-throttle control scheme

combines CAN bus digital signals and PWM

analog signals to improve the real-time

response and anti-interference

performance of the system and ensure

flight safety.

- Multi-Protection for

Safer Flight - Integrate a variety of software and

hardware protection mechanisms,

including overcurrent, stalling, throttle

loss, temperature anomaly monitoring,

and low-voltage and high-voltage

protection, ensuring comprehensive

safety for flight.

- Long-Time and

Wide-Temperature

Range Verification - This product passes through the lab life test for over 1,000 hours in the

temperature range of -40°C to 65°C and

over 500 hours of real-flight verification.

- The ESC undergoes stringent industry tests, including drive compatibility tests,

- temperature/humidity combined vibration tests, and high and low-temperature tests.

- These ensure the stable operation of the propulsion system at all times in various complex environments.

- Drive performance test

- Functional

impact test

- 0~600 Hz & 10G

vibration test

- High and low-temperature

start/stop test

- High and low-temperature

operation test

- High and low-temperature

storage test

- Temperature cycling test

- Temperature

gradient test

- Dust ingress testing

- Water ingress testing

- Thermal shock test

- Load endurance test

vibration test>

temperature test>

and Fully Compatible

- Well-designed and highly adaptable

- Adhering to the positive design concept of HOBBYWING, this product

- is adapted to 60mm tube diameter and 2.5mm wall thickness after

- strength analysis and reliability verification, which can be seamlessly

- integrated with the mainstream heavy-lift frames in the market.

- Convenient Installation Design

- With the high-strength aluminum alloy molded motor base, the motor is highly integrated with the ESC. The tube clip holder is designed with four-direction locking, allowing for quick installation without disassembling and assembling the motor and ESC, thus enhancing efficiency and reliability.

- Intelligent Control Fault Prompts

- Equipped with a built-in intelligent monitoring system, the device provides real-time fault status updates through an LED display, allowing for quick diagnosis.

- Open Parameter Adjustment and

Firmware OTA Upgrade - With HOBBYWING’s proprietary host computer software DataLink, users can adjust drive parameters, steering, and light color effortlessly to optimize flight performance and upgrade the latest firmware.

- Wide Range of Flight Control

Compatibility - This system supports DroneCAN protocol and intercommunication with multiple mainstream flight control systems, such as ArduPilot open source ecosystem, VK, Byaero and Jiyi. It also supports CAN communication to build an intelligent flight ecosystem.

- Real-Time Data Interaction

- Real-time data interaction with the flight control system is made available via the CAN interface for monitoring key flight parameters, such as speed, throttle, current, voltage and temperature. This allows for fast data analysis and timely response while enhancing safety.

- Independent Black Box

- The built-in black box of the ESC automatically stores real-time operation data and fault codes of the propulsion system for quick location and diagnosis of faults.

Storage of Propellers

- Specially designed for H13, this quick-assembly propeller mounting base is compatible with 57x20" and 54x20" installation holes

- It eliminates the hassle of large propeller assembly, making storage and transportation more space-efficient and effective.

Service

- 1 Customizable extension cables of different

sizes and lengths; - 2 Customizable tilt adapters of the tube clip

holder with different angles; - 3Customizable motor temperature monitoring

and propeller locking function; - 4Optional carbon fiber straight propellers or

folding propellers as needed.

Configuration

- Takeoff weight

- 180kg

- Rated thrust

- 45kg

- Recommended payload

- 100kg

- Endurance

- 20min+

- Recommended battery

- 24S 70000mAh*2

- Flight Time

- 20min+

- HOBBYWING is one of the world’s earliest professional manufacturers of UAV motors and ESCs,

- serving over 500 UAV manufacturers. The UAV propulsion systems produced have an accumulative flight time of 50 million hours.

- Flight Time

- 5000W+Hours

- Serving

- 500+UAV Manufacturers

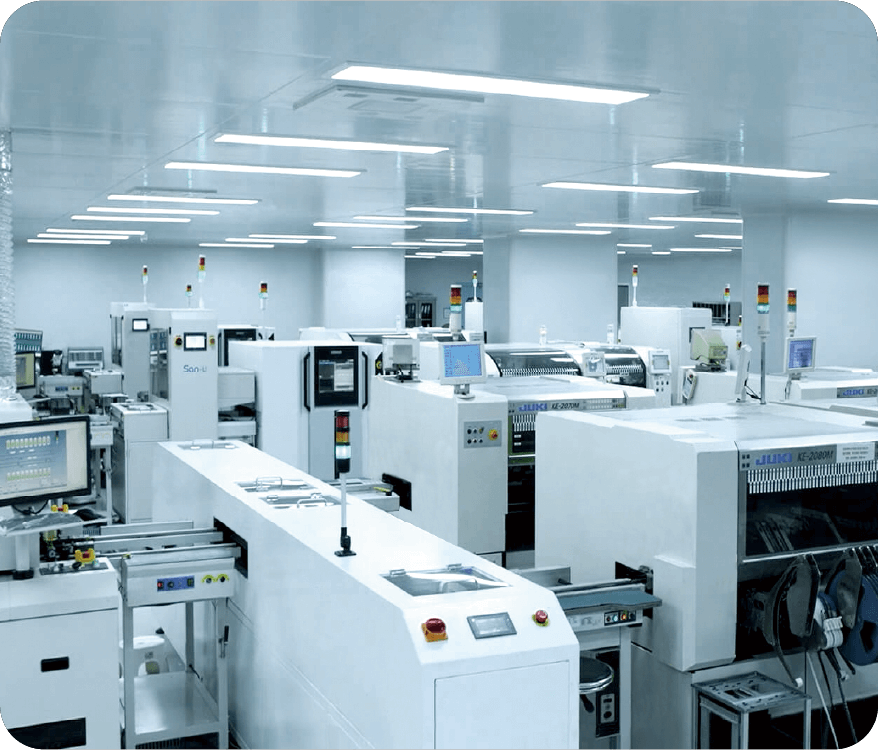

- Full Manufacturing Chain

Advantages - The complete manufacturing chain of SMT, precision machining, precision injection molding, automated wire making, and automated assembly strongly guarantee the high quality level of products from design to manufacturing.

- Pre-Sales Technical Support

- Our dedicated FAE team provides pre-sales consultation to ensure that users receive the most suitable UAV propulsion products and customized solutions.

- After-Sales Professional Maintenance

- Our professional after-sales maintenance team promises to provide users with rapid and efficient maintenance services to safeguard their interests.

- Mature Sales Channels

- With two decades of experience, worldwide sales channels are established,

ensuring that our products and services are easily accessible to customers.

-

- Thank you for your interest in HOBBYWING propulsion systems! For customized solutions, please provide your contact information and technical requirements, and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

| Product Name |

|

||||||||||||||||||||||||||||||||||||||||||

| Specifications |

|

||||||||||||||||||||||||||||||||||||||||||

| Motor |

|

||||||||||||||||||||||||||||||||||||||||||

| ESC |

|

||||||||||||||||||||||||||||||||||||||||||

| Propeller |

|

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

92V (24S LiPo) |

MSC 54x20 |

33% |

17501 |

18.1 |

1667 |

86 |

10.5 |

86℃ |

|

35% |

18490 |

19.5 |

1794 |

86 |

10.3 |

|||

|

37% |

20581 |

22.5 |

2066 |

87 |

10.0 |

|||

|

39% |

22800 |

25.8 |

2372 |

88 |

9.6 |

|||

|

41% |

25125 |

29.5 |

2719 |

89 |

9.6 |

|||

|

43% |

27541 |

33.8 |

3109 |

89 |

8.9 |

|||

|

45% |

30036 |

38.5 |

3539 |

89 |

8.5 |

|||

|

47% |

32603 |

43.5 |

4005 |

89 |

8.1 |

|||

|

49% |

35239 |

48.9 |

4502 |

89 |

7.8 |

|||

|

51% |

37944 |

54.6 |

5028 |

89 |

7.5 |

|||

|

53% |

40718 |

60.6 |

5580 |

89 |

7.3 |

|||

|

55% |

45125 |

71.8 |

6339 |

90 |

6.8 |

|||

|

58% |

47982 |

77.9 |

7170 |

90 |

6.7 |

|||

|

61% |

52586 |

87.8 |

8076 |

90 |

6.5 |

|||

|

63% |

55764 |

95.6 |

8795 |

90 |

6.3 |

|||

|

65% |

59031 |

103.9 |

9565 |

90 |

6.2 |

|||

|

68% |

64093 |

117.7 |

10830 |

90 |

5.9 |

|||

|

71% |

69330 |

133.0 |

12241 |

89 |

5.7 |

|||

|

75% |

76515 |

156.0 |

14359 |

89 |

5.3 |

|||

|

80% |

85567 |

188.2 |

17316 |

87 |

4.9 |

|||

|

85% |

94162 |

221.5 |

20384 |

86 |

4.6 |

|||

|

100% |

106991 |

273.6 |

25177 |

83 |

4.2 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

108V (28S LiPo) |

MSC 54x20 |

33% |

17914 |

16.2 |

1746 |

85.8 |

10.3 |

80℃ |

|

35% |

18957 |

17.4 |

1883 |

86.2 |

10.1 |

|||

|

37% |

21158 |

20.2 |

2178 |

87.1 |

9.7 |

|||

|

39% |

23491 |

23.2 |

2510 |

87.9 |

9.4 |

|||

|

41% |

25937 |

26.7 |

2885 |

88.5 |

9.0 |

|||

|

43% |

28482 |

30.6 |

3303 |

88.9 |

8.6 |

|||

|

45% |

31114 |

34.8 |

3762 |

89.1 |

8.3 |

|||

|

46% |

32460 |

37.1 |

4006 |

89.2 |

8.1 |

|||

|

48% |

35211 |

41.8 |

4520 |

89.3 |

7.8 |

|||

|

51% |

39477 |

49.6 |

5353 |

89.5 |

7.4 |

|||

|

53% |

42414 |

55.1 |

5947 |

89.6 |

7.1 |

|||

|

55% |

45426 |

60.8 |

6573 |

89.7 |

6.9 |

|||

|

58% |

50091 |

70.1 |

7573 |

89.8v |

6.6 |

|||

|

61% |

54935 |

80.2 |

8659 |

89.8 |

6.3 |

|||

|

63% |

58266 |

87.4 |

9439 |

89.7 |

6.2 |

|||

|

65% |

61676 |

95.1 |

10270 |

89.6 |

6.0 |

|||

|

68% |

66931 |

107.6 |

11623 |

89.3 |

5.8 |

|||

|

71% |

72332 |

121.4 |

13115 |

88.8 |

5.5 |

|||

|

75% |

79680 |

141.8 |

15320 |

88.0 |

5.2 |

|||

|

80% |

88845 |

169.9 |

18358 |

86.7 |

4.8 |

|||

|

85% |

97474 |

198.9 |

21491 |

85.1 |

4.5 |

|||

|

100% |

110511 |

245.8 |

26556 |

81.7 |

4.2 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

92V (24S LiPo) |

MSC 57x20 |

33% |

20407 |

21.6 |

1988 |

86 |

10.3 |

84℃ |

|

35% |

21552 |

23.1 |

2125 |

87 |

10.1 |

|||

|

37% |

23988 |

26.4 |

2434 |

88 |

9.9 |

|||

|

39% |

26580 |

30.4 |

2801 |

89 |

9.5 |

|||

|

41% |

29291 |

35.1 |

3230 |

89 |

9.1 |

|||

|

43% |

32092 |

40.4 |

3714 |

89 |

8.6 |

|||

|

45% |

34965 |

46.1 |

4246 |

89 |

8.2 |

|||

|

47% |

37896 |

52.3 |

4814 |

88 |

7.9 |

|||

|

49% |

40877 |

58.8 |

5410 |

88 |

7.6 |

|||

|

51% |

43907 |

65.5 |

6027 |

88 |

7.3 |

|||

|

52% |

45440 |

68.9 |

6343 |

88 |

7.2 |

|||

|

53% |

46986 |

72.4 |

6663 |

88 |

7.1 |

|||

|

56% |

51708 |

83.1 |

7652 |

89 |

6.8 |

|||

|

59% |

56572 |

94.6 |

8703 |

89 |

6.5 |

|||

|

62% |

61603 |

107.0 |

9847 |

89 |

6.3 |

|||

|

65% |

66816 |

120.9 |

11122 |

89 |

6.0 |

|||

|

68% |

72217 |

136.5 |

12560 |

88 |

5.7 |

|||

|

71% |

77787 |

154.1 |

14181 |

87 |

5.5 |

|||

|

75% |

85394 |

180.5 |

16614 |

86 |

5.1 |

|||

|

80% |

94870 |

216.5 |

19928 |

84 |

4.8 |

|||

|

85% |

103599 |

251.2 |

23117 |

82 |

4.5 |

|||

|

100% |

112566 |

284.5 |

26185 |

80 |

4.3 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Efficiency(%) |

Efficiency(g/W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|

|

108V (28S LiPo) |

MSC 57x20 |

33% |

21109 |

19.6 |

2115 |

86 |

10.0 |

79℃ |

|

35% |

22328 |

20.8 |

2249 |

87 |

9.9 |

|||

|

37% |

24898 |

23.9 |

2581 |

88 |

9.6 |

|||

|

39% |

27613 |

27.7 |

2990 |

88 |

9.2 |

|||

|

41% |

30447 |

32.1 |

3464 |

88 |

8.8 |

|||

|

43% |

33376 |

36.9 |

3991 |

88 |

8.4 |

|||

|

45% |

36386 |

42.2 |

4558 |

88 |

8.0 |

|||

|

47% |

39466 |

47.7 |

5156 |

88 |

7.7 |

|||

|

49% |

42610 |

53.5 |

5780 |

88 |

7.4 |

|||

|

50% |

44205 |

56.5 |

6101 |

88 |

7.2 |

|||

|

51% |

45815 |

59.5 |

6428 |

88 |

7.1 |

|||

|

52% |

47440 |

62.6 |

6760 |

88 |

7.0 |

|||

|

55% |

52407 |

72.2 |

7796 |

88 |

6.7 |

|||

|

57% |

55799 |

78.9 |

8527 |

89 |

6.5 |

|||

|

60% |

61013 |

89.8 |

9702 |

89 |

6.3 |

|||

|

65% |

70049 |

110.6 |

11945 |

88 |

5.9 |

|||

|

68% |

75659 |

124.9 |

13494 |

88 |

5.6 |

|||

|

71% |

81373 |

140.7 |

15203 |

87 |

5.4 |

|||

|

75% |

89035 |

163.7 |

17687 |

85 |

5.0 |

|||

|

80% |

98321 |

193.7 |

20928 |

84 |

4.7 |

|||

|

85% |

106542 |

221.2 |

23893 |

82 |

4.5 |

|||

|

100% |

113038 |

243.3 |

26282 |

80 |

4 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.

Buy

Buy