Source : HOBBYWINGDate : 9th Oct 2025

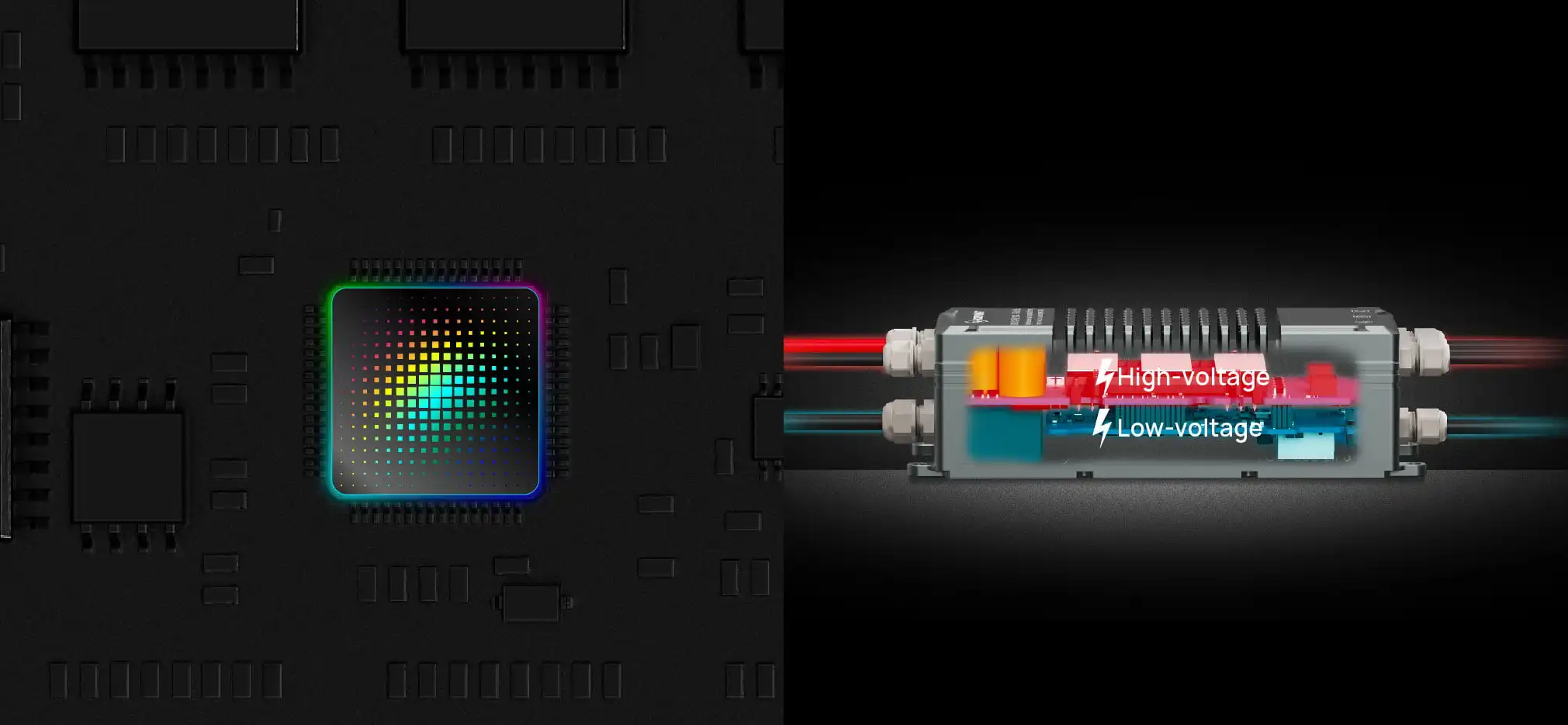

Software: adopts rigorous modular design and various redundancy strategies.

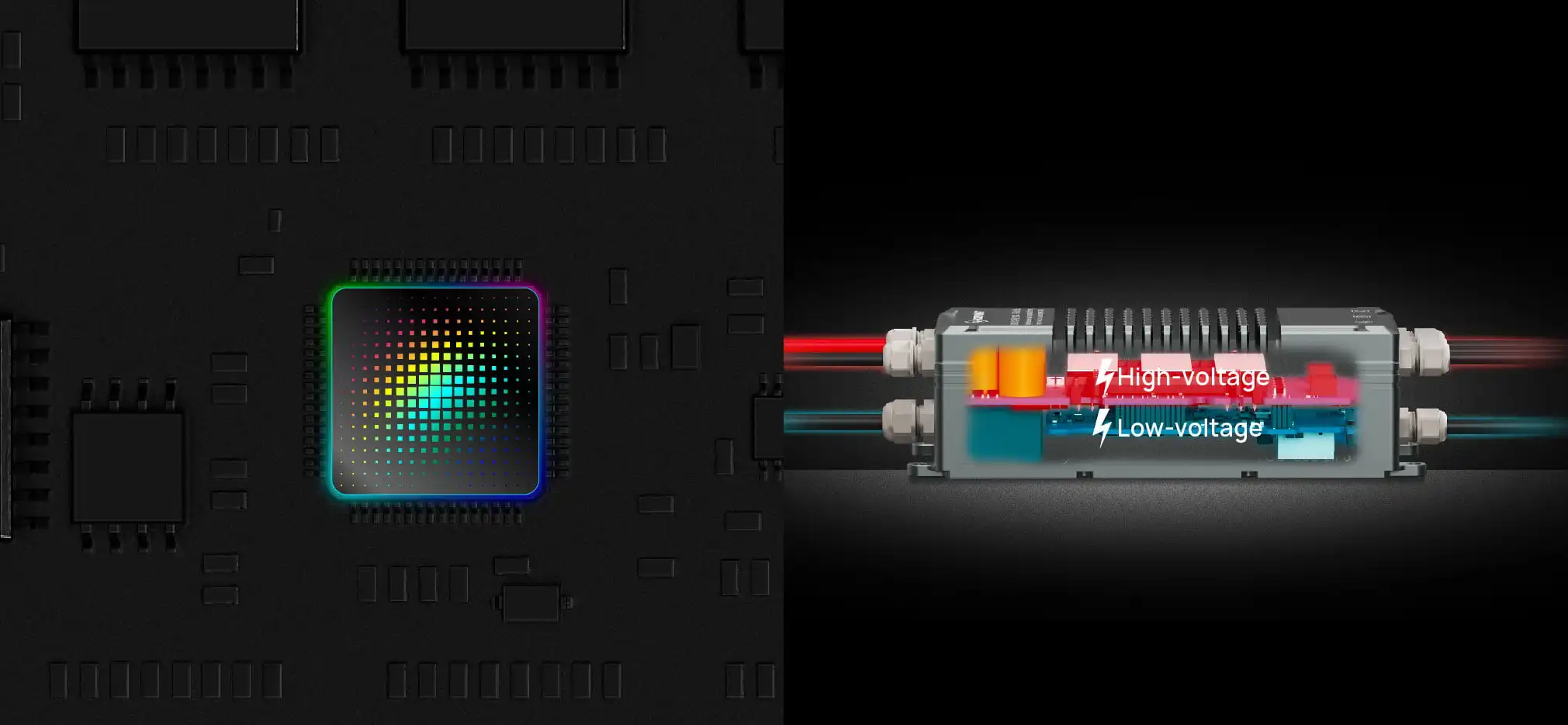

Hardware: the Protective Earth (PE) is completely isolated from the high-voltage power circuits and low-voltage signal circuits, ensuring superior system reliability.

The motor, ESC, and propellers are all independently developed by HOBBYWING, with precise control over every detail.

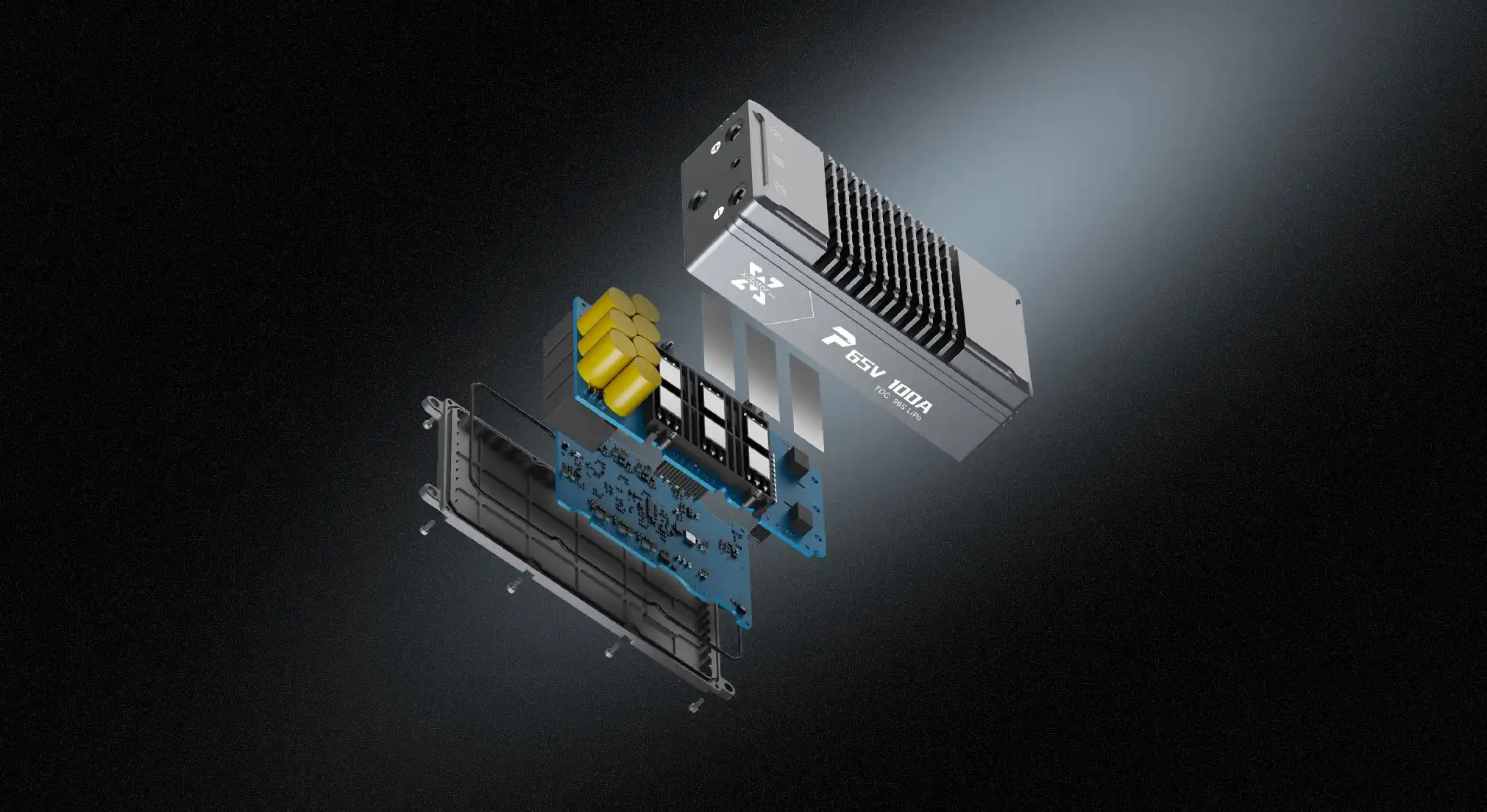

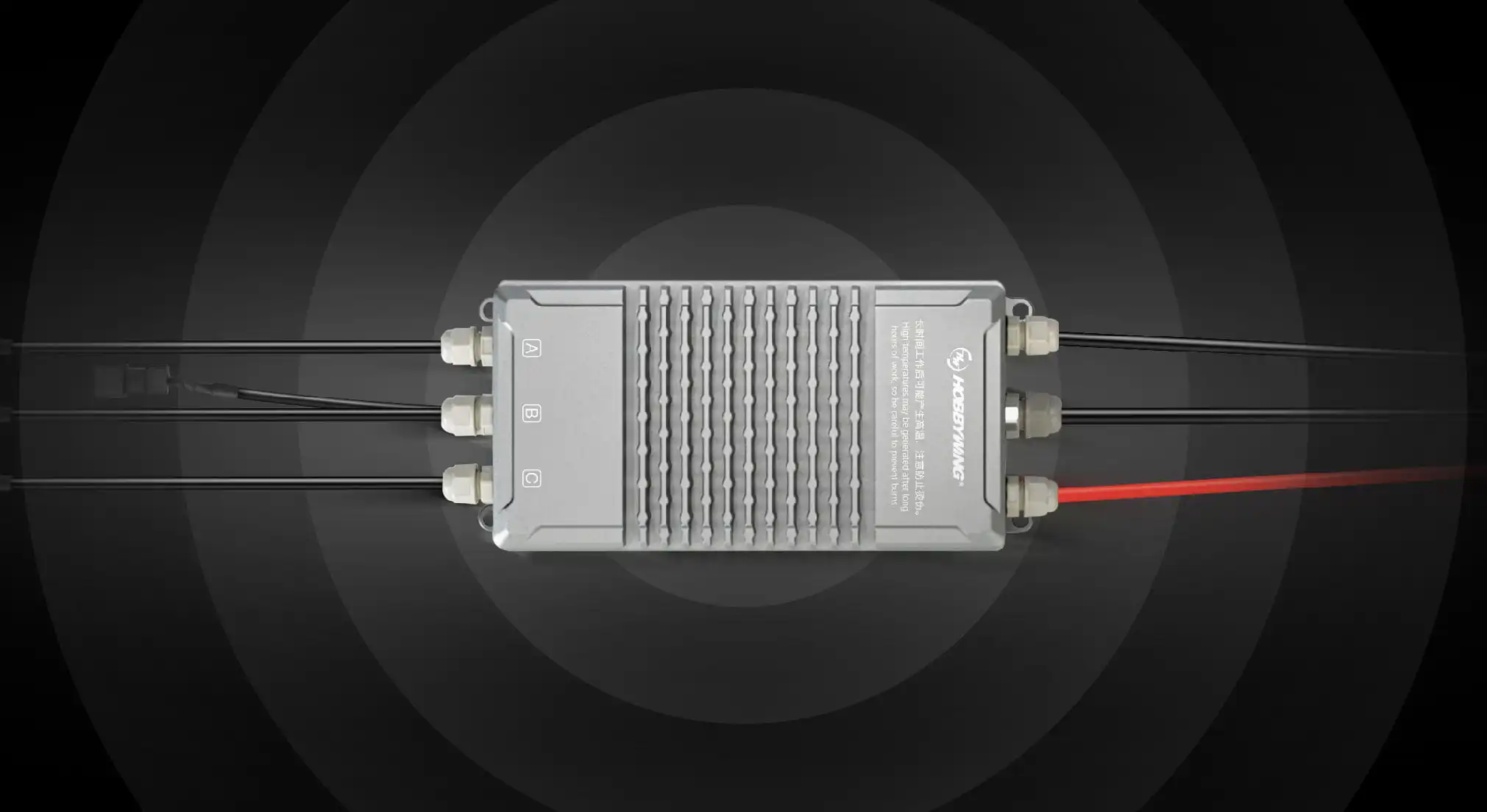

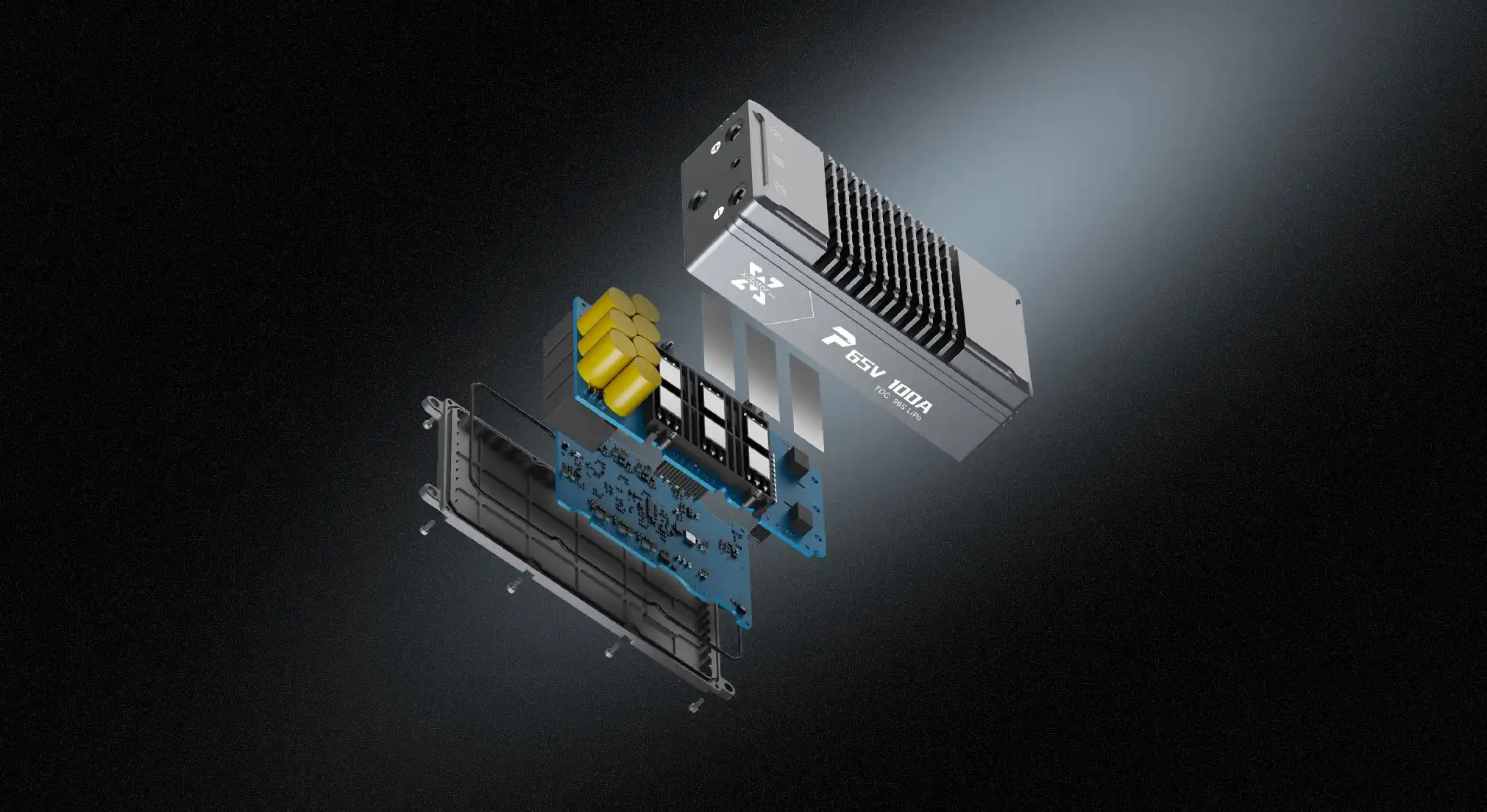

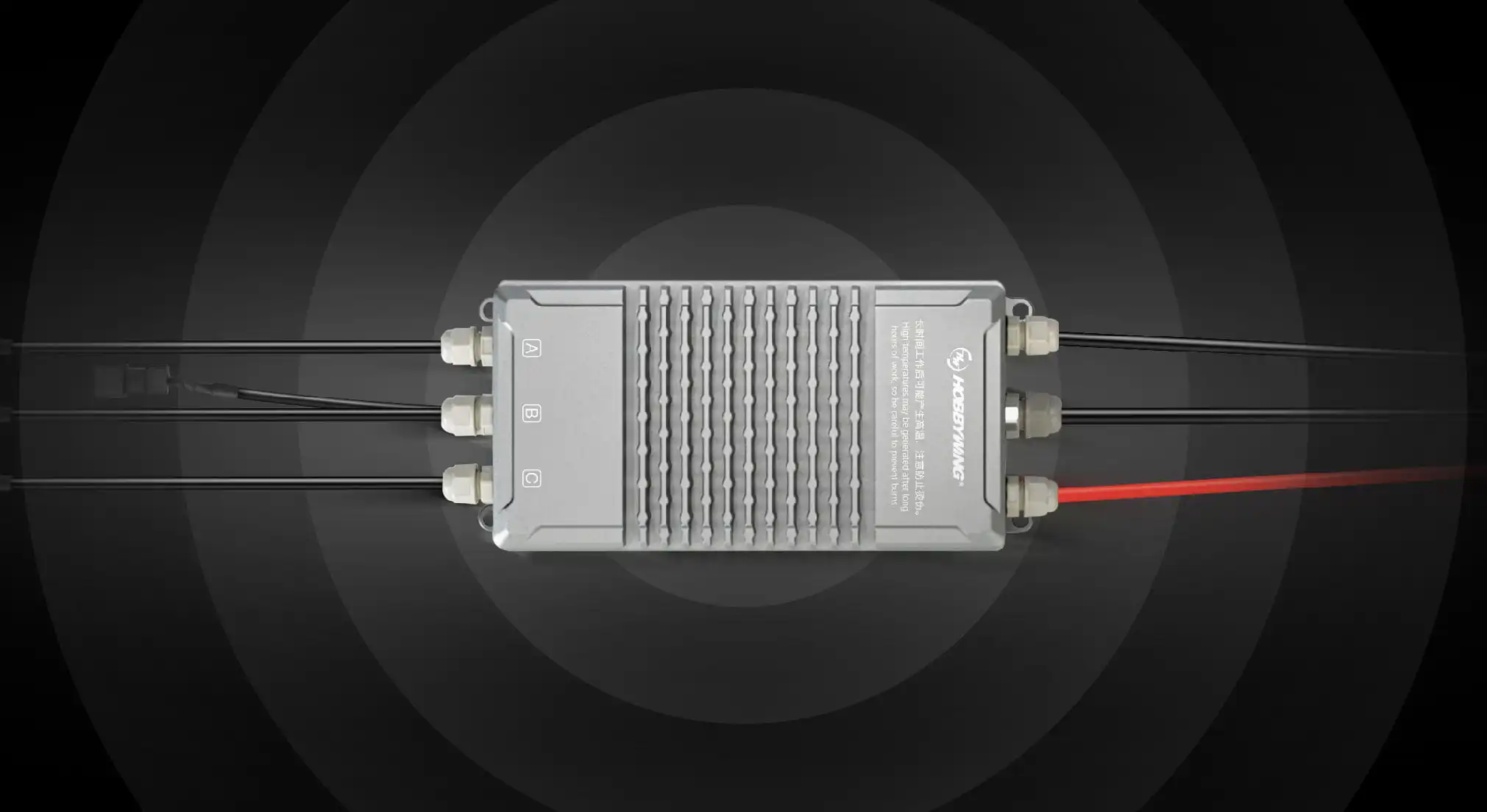

100A FOC ESC: uses automotive-grade components with higher temperature resistance.

15635 11KV Motor: made of high temperature resistant material, combined with the dual design of knurl shaft and screws to avoid loosening.

The propeller adopts carbon fiber molding process and is aerodynamically with a large aspect ratio, a small windward side, and a propeller tip with a low wind resistance, striking an optimal balance between efficiency and thrust capacity.This design is tailored for the specific application requirements of VTOLs.

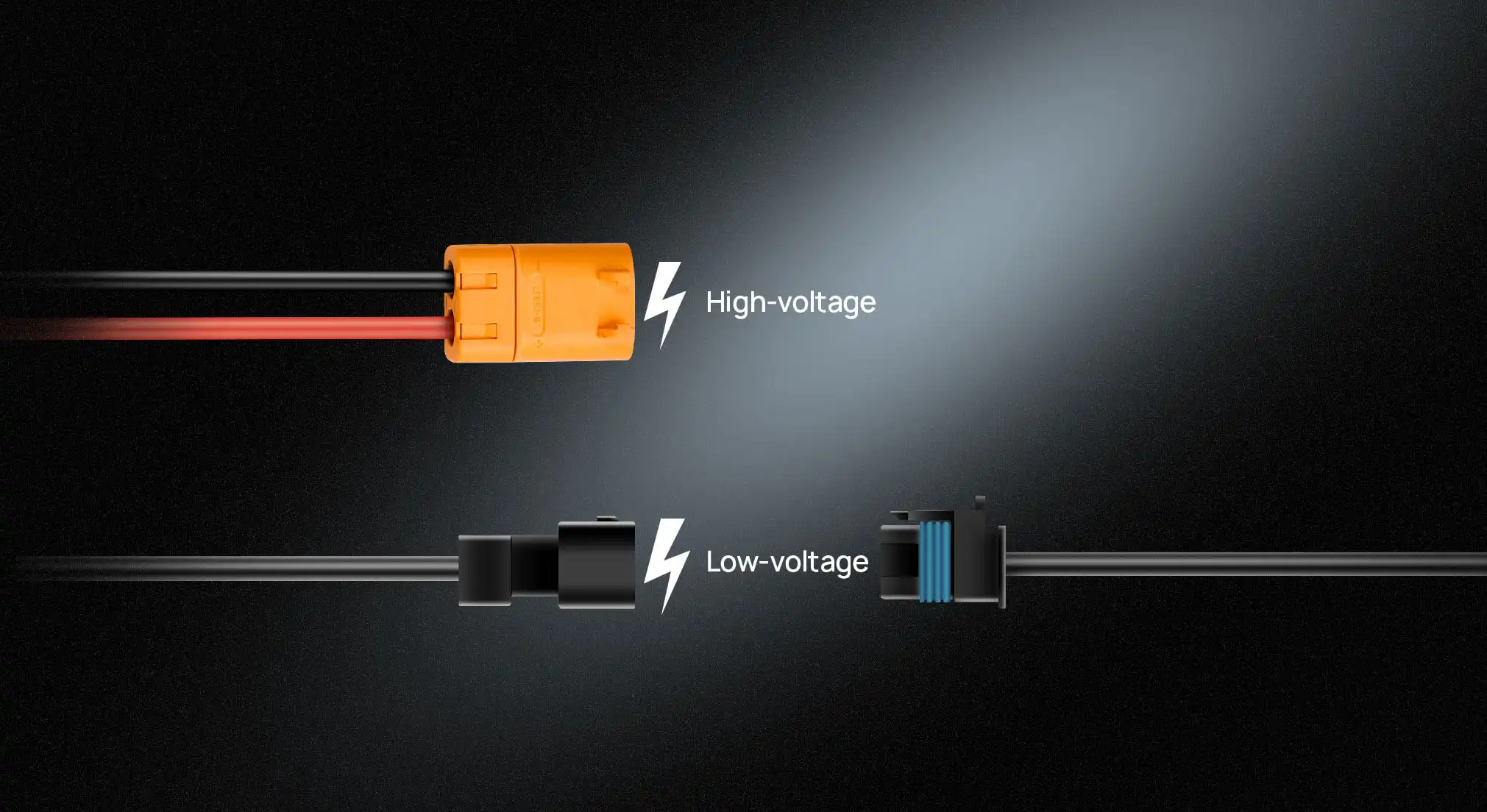

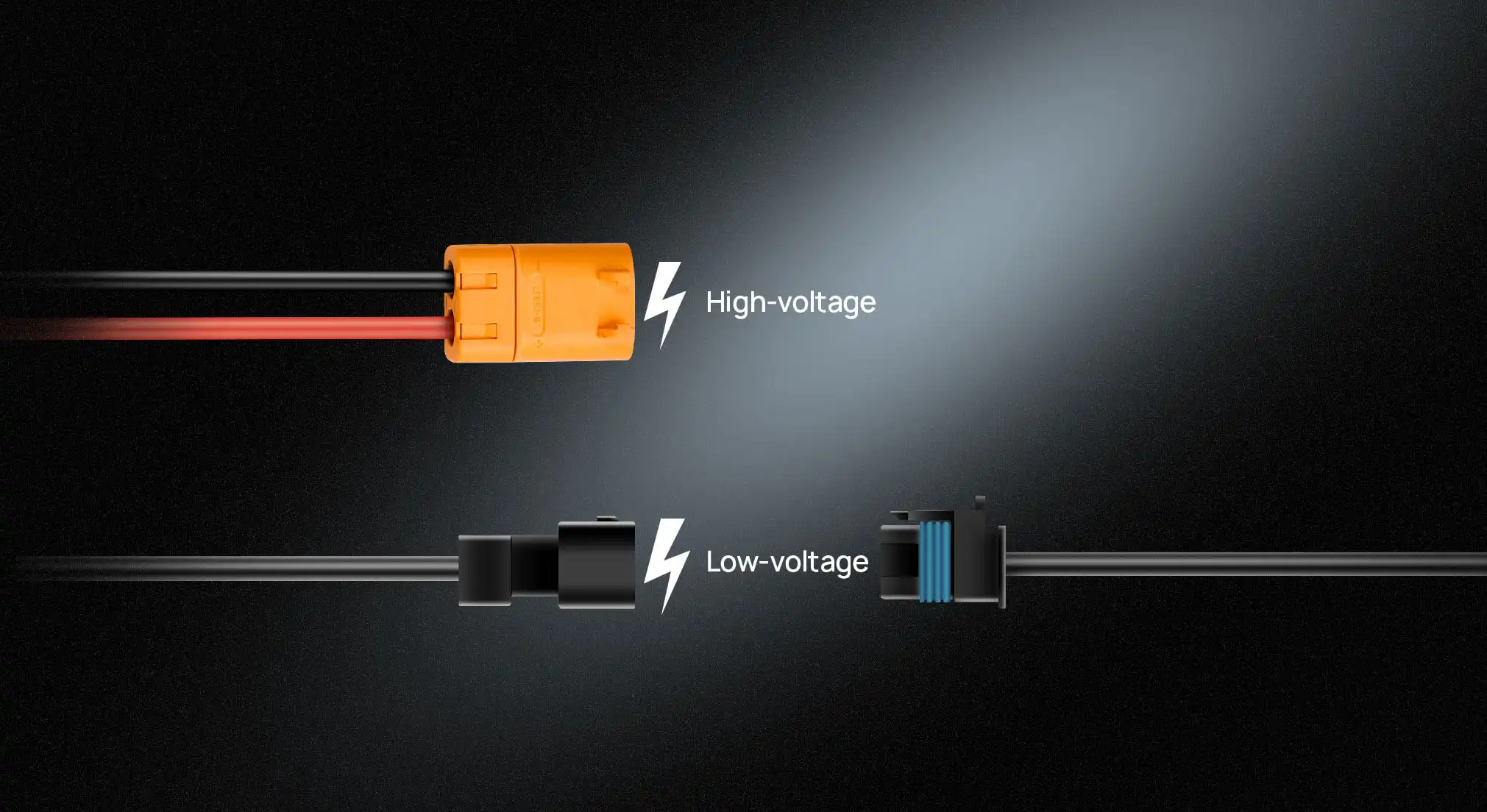

High-voltage and low-voltage signal connectors: constructed with automotive-grade materials, featuring fool-proof design, prevention of poor contact, and vibration resistancem, providing reliable system connectivity and extended service life.

Obtain RPM information in real time through dual channels, to meet airworthiness certification requirements and easily respond to future regulatory requirements.

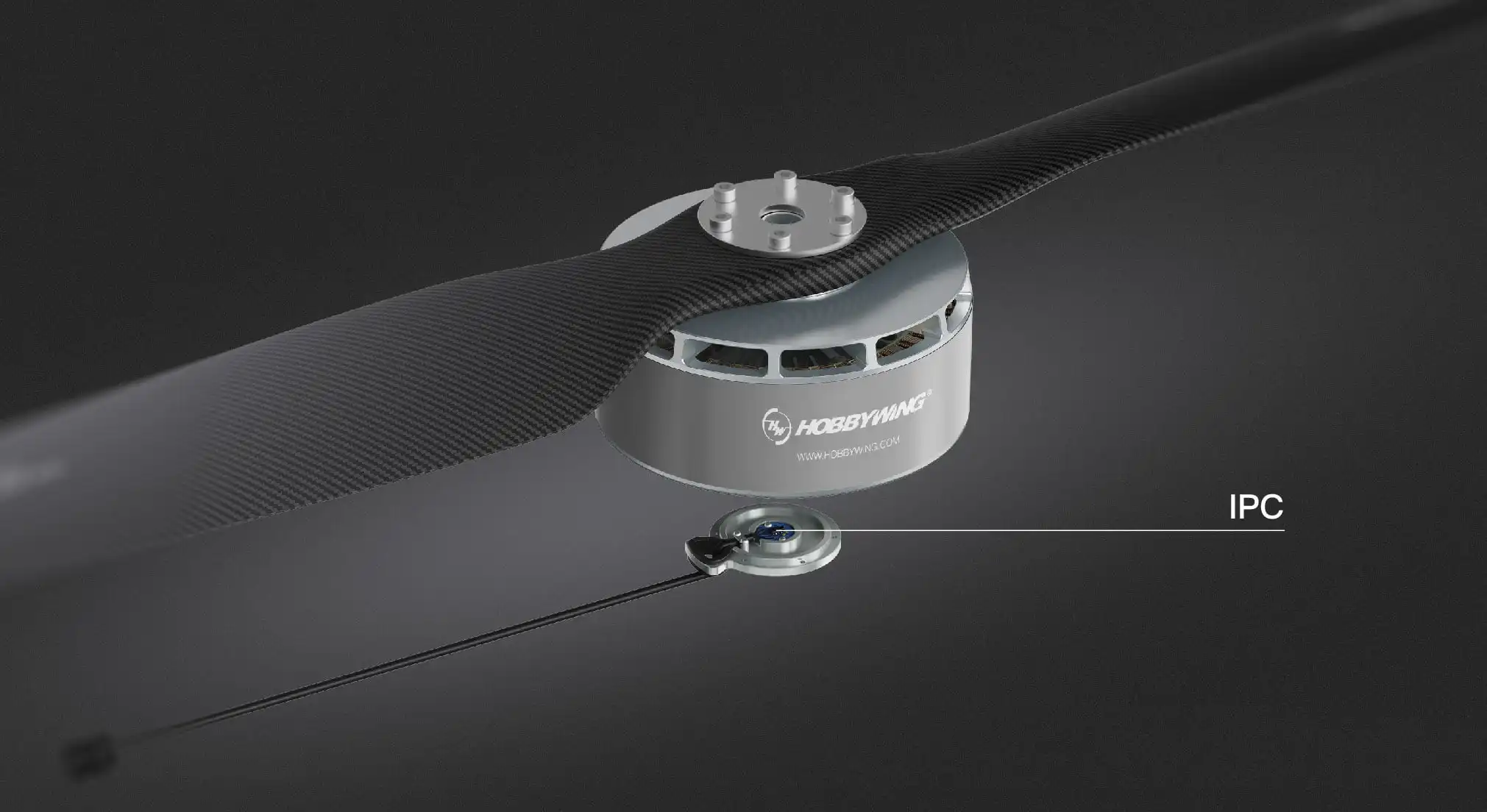

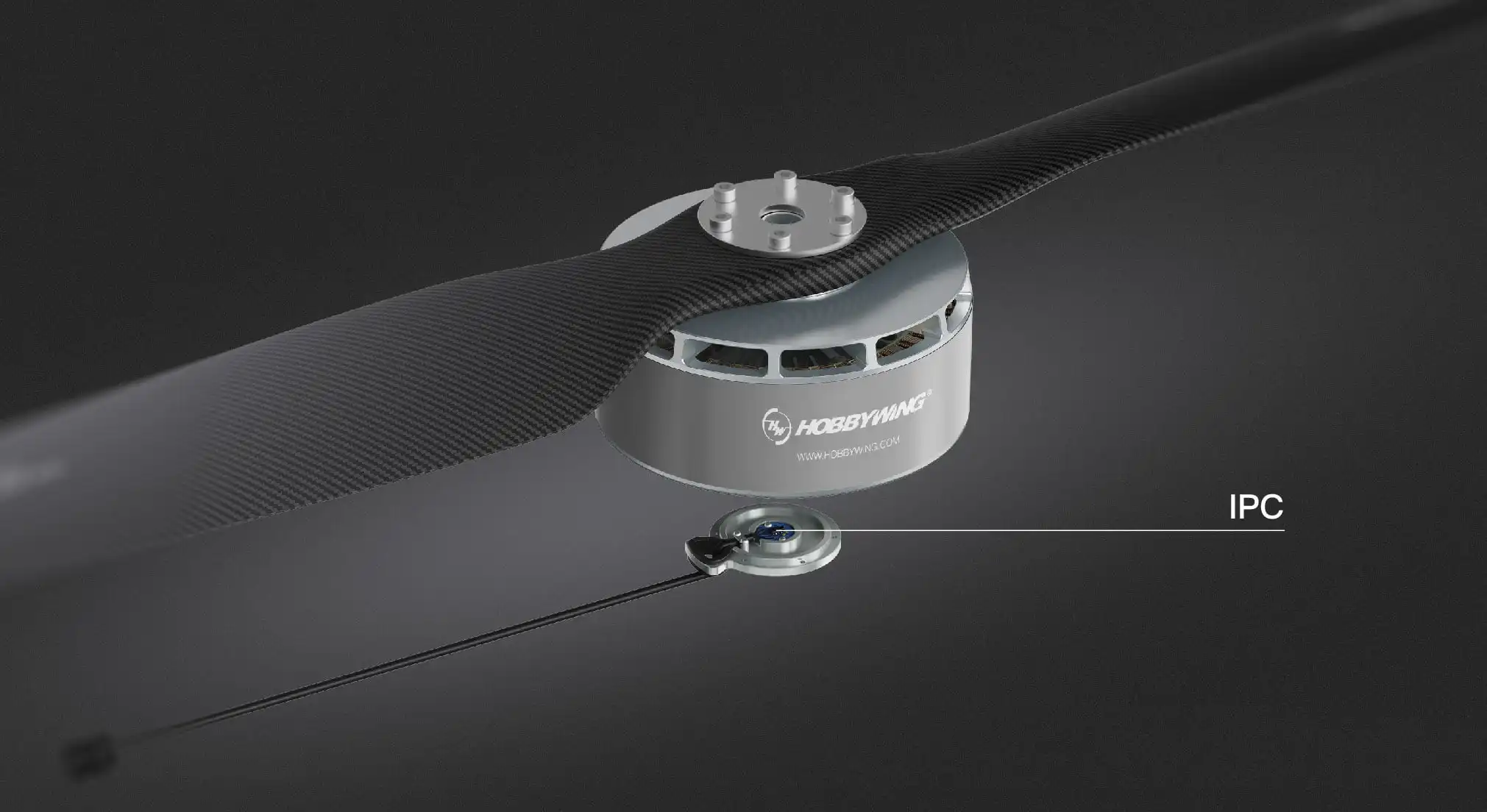

IPC function for the flexible setting of the propeller stopping position, reduces the resistance of the UAV during cruise flight and extends the flight endurance.

The 100A FOC Drone ESC supports dual bus communication protocols: CAN and RS485, and Provides triple throttle control modes as follows: CAN+RS485 (defalt), CAN+PWM(optional), RS485+PWM (optional)

The dual signal channels of sensored driven mode and sensorless driven mode can be converted in real time to enhance the reliability of the propulsion system.

(Sensored Driven: a physical RPM sensor is used to directly obtain the RPM signal for motor control)

(Sensorless Driven: without a physical RPM sensor, the RPM signal is obtained through software algorithms)

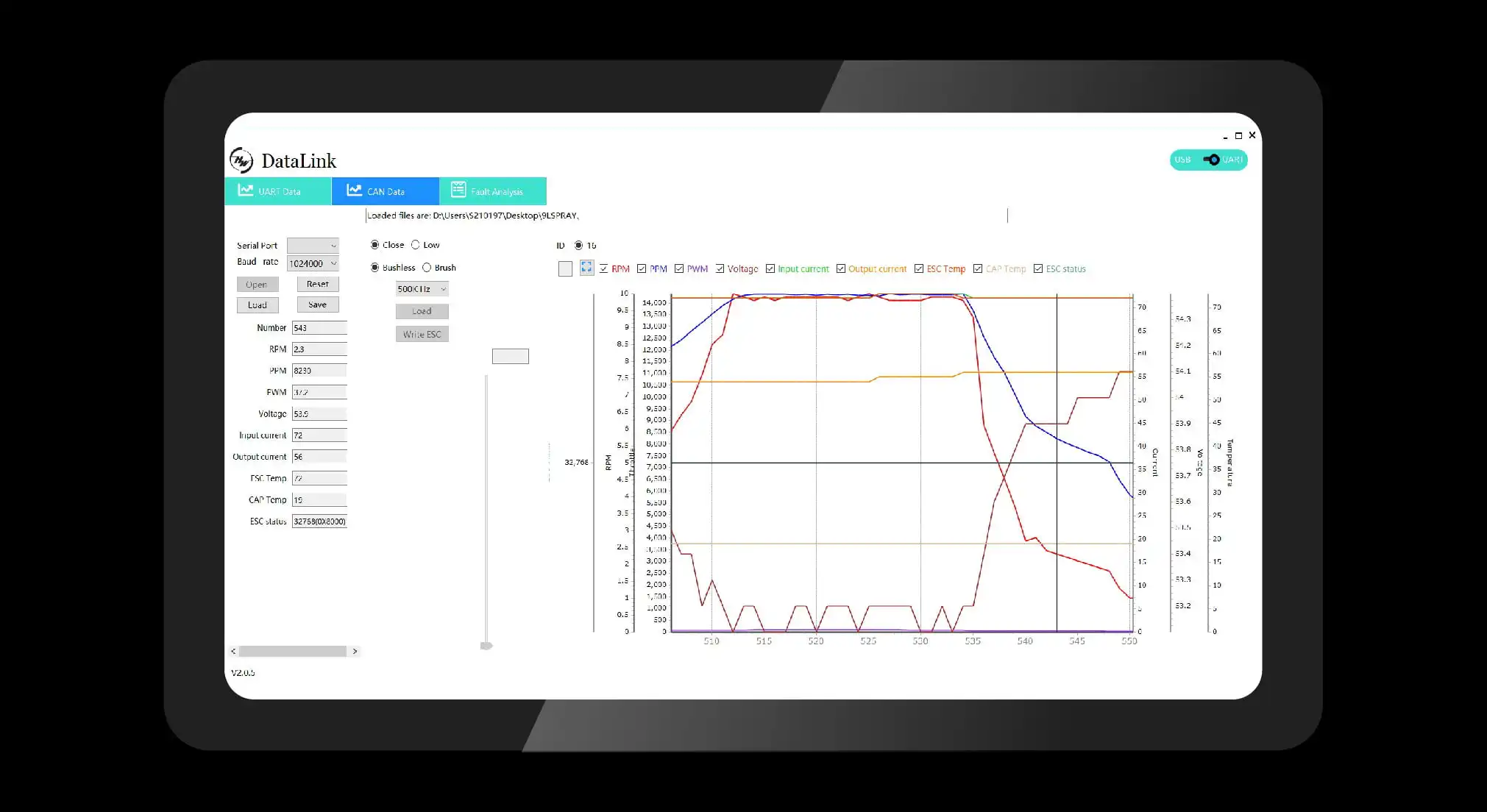

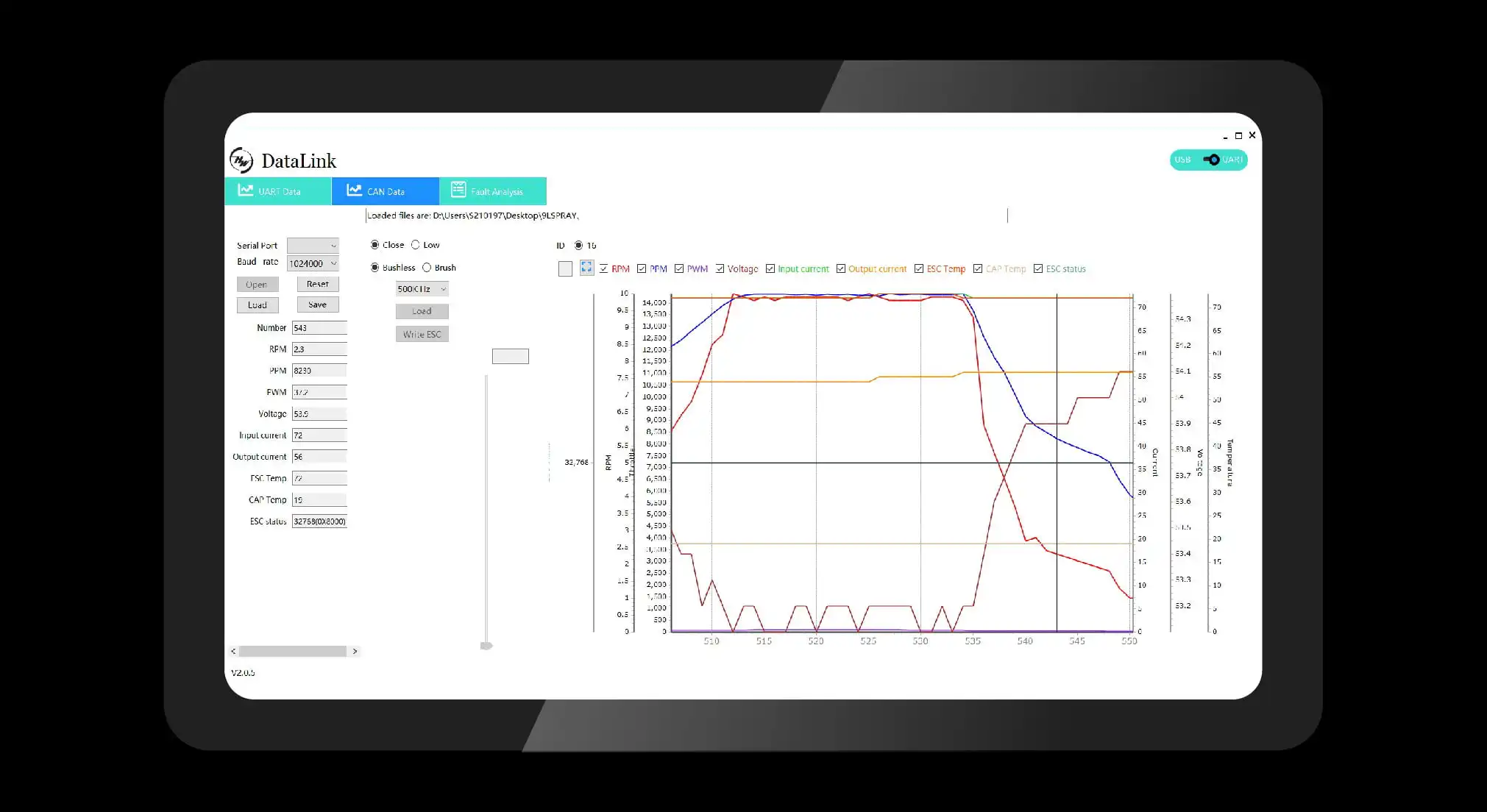

The fault storage function records operational fault codes during operation, enabling precise root cause tracing

The system continuously records the drone's operational data for 2-48 hours, facilitating comprehensive post-flight data analysis.

Real-time detection and feedback of coil temperature is supported, for real-time monitoring of motor temperature rise, ensuring safe flight.

2000V-rated insulation and withstand voltage design, verified by over 1000 hours of continuous aging testing, ensures maintenance-free operation throughout its entire lifecycle.

Source:HOBBYWINGDate: 9th Oct 2025

Software: adopts rigorous modular design and various redundancy strategies.

Hardware: the Protective Earth (PE) is completely isolated from the high-voltage power circuits and low-voltage signal circuits, ensuring superior system reliability.

The motor, ESC, and propellers are all independently developed by HOBBYWING, with precise control over every detail.

100A FOC ESC: uses automotive-grade components with higher temperature resistance.

15635 11KV Motor: made of high temperature resistant material, combined with the dual design of knurl shaft and screws to avoid loosening.

The propeller adopts carbon fiber molding process and is aerodynamically with a large aspect ratio, a small windward side, and a propeller tip with a low wind resistance, striking an optimal balance between efficiency and thrust capacity.This design is tailored for the specific application requirements of VTOLs.

High-voltage and low-voltage signal connectors: constructed with automotive-grade materials, featuring fool-proof design, prevention of poor contact, and vibration resistancem, providing reliable system connectivity and extended service life.

Obtain RPM information in real time through dual channels, to meet airworthiness certification requirements and easily respond to future regulatory requirements.

IPC function for the flexible setting of the propeller stopping position, reduces the resistance of the UAV during cruise flight and extends the flight endurance.

The 100A FOC Drone ESC supports dual bus communication protocols: CAN and RS485, and Provides triple throttle control modes as follows: CAN+RS485 (defalt), CAN+PWM(optional), RS485+PWM (optional)

The dual signal channels of sensored driven mode and sensorless driven mode can be converted in real time to enhance the reliability of the propulsion system.

(Sensored Driven: a physical RPM sensor is used to directly obtain the RPM signal for motor control)

(Sensorless Driven: without a physical RPM sensor, the RPM signal is obtained through software algorithms)

The fault storage function records operational fault codes during operation, enabling precise root cause tracing

The system continuously records the drone's operational data for 2-48 hours, facilitating comprehensive post-flight data analysis.

Real-time detection and feedback of coil temperature is supported, for real-time monitoring of motor temperature rise, ensuring safe flight.

2000V-rated insulation and withstand voltage design, verified by over 1000 hours of continuous aging testing, ensures maintenance-free operation throughout its entire lifecycle.