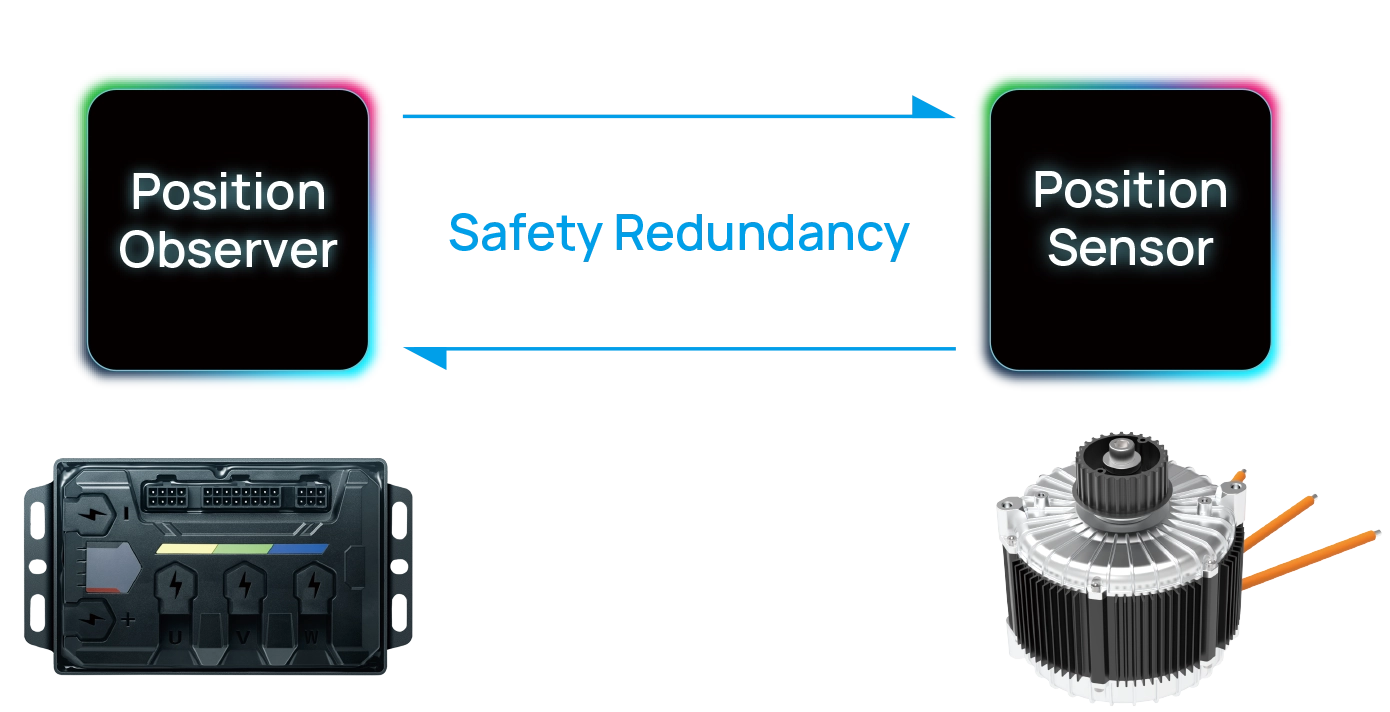

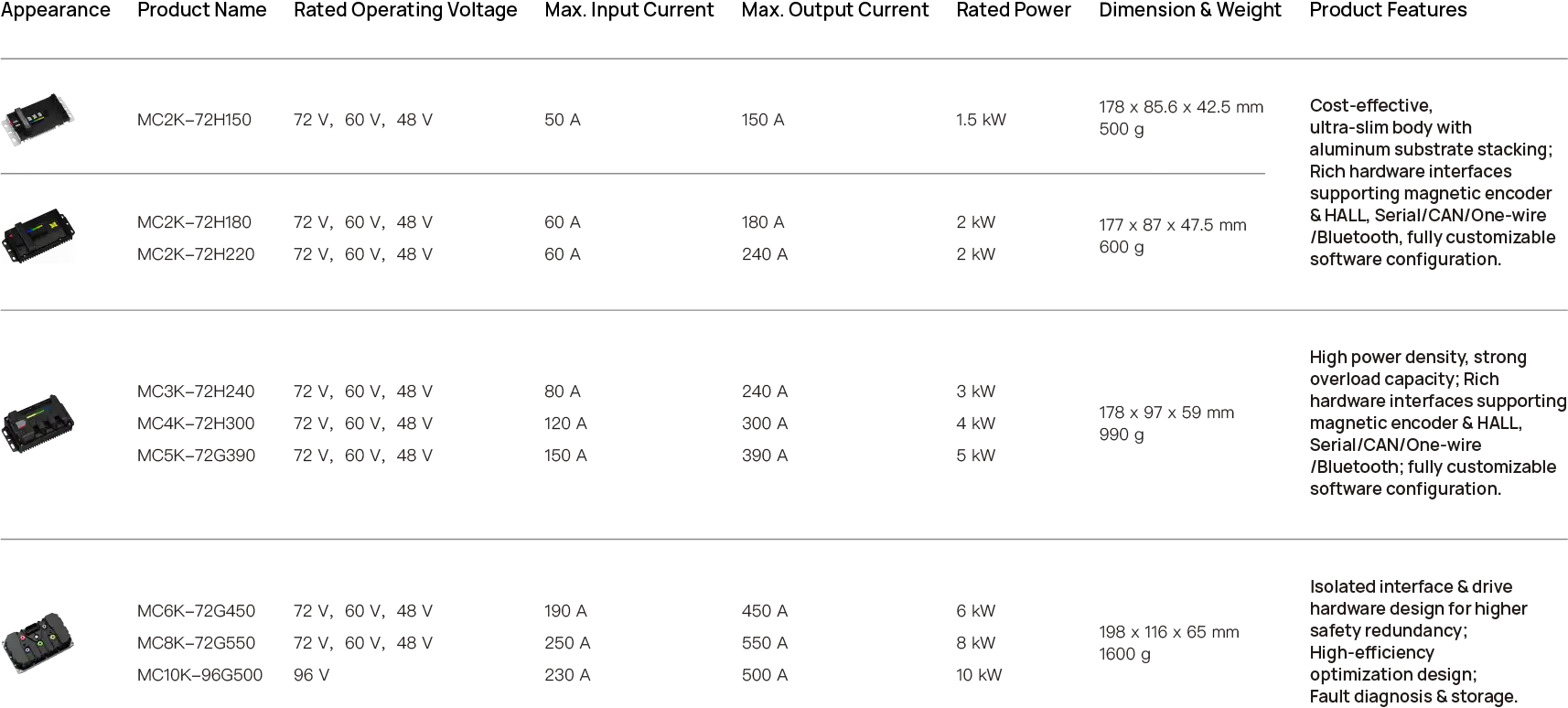

Our electric motorcycle motor controller is equipped with position observer and position sensor safety redundancy technology.

In case of sudden motor sensor failure or poor wiring connection, the system can smoothly switch to sensorless vector control mode,

avoiding risks such as power interruption and sudden jitter in real time, and maintaining stable and continuous power output.

Whether a sensor fails unexpectedly during urban commuting or wiring is affected by bumps during mountain riding,

this electric motorcycle controller prevents sudden breakdown on the road and provides reliable support for users' travel.

The electric motorcycle ECU adopts a dual-layer architecture design for its software, which monitors current, voltage, temperature, speed, and rotor position in real time. Once values exceed limits, it immediately issues an early warning and enters safety mode.

This electric motorcycle controller adopts measures including internal/external clock backup, key signal backup, and core data backup to significantly improve system fault tolerance. Even if components vibrate on bumpy roads or parts wear out in extreme environments, the electric motorcycle motor controller system can still maintain normal overall functionality. It effectively prevents ride interruption caused by sudden malfunctions, creating an "all-weather, all-road" reliable user experience while helping manufacturers reduce after-sales complaints due to electric motorcycle controller faults.

The electric motorcycle controller has passed IP67 waterproof rating testing, -40℃~85℃ high-low temperature cycle testing,

48-hour salt spray testing, and swept-sine/random vibration testing,

complying with national standards GB/T 18387 and GB 34660. Whether for wading rides in the rainy season,

low-temperature startup in the cold winter, or salt spray corrosion environments in coastal areas,

the electric motorcycle controller maintains stable performance.

This helps manufacturers reduce cross-regional after-sales risks and strengthen brand reputation.

The electric motorcycle controller has passed IP67 waterproof rating testing, -40℃~85℃ high-low temperature cycle testing,

48-hour salt spray testing, and swept-sine/random vibration testing,

complying with national standards GB/T 18387 and GB 34660. Whether for wading rides in the rainy season,

low-temperature startup in the cold winter, or salt spray corrosion environments in coastal areas,

the electric motorcycle controller maintains stable performance.

This helps manufacturers reduce cross-regional after-sales risks and strengthen brand reputation.

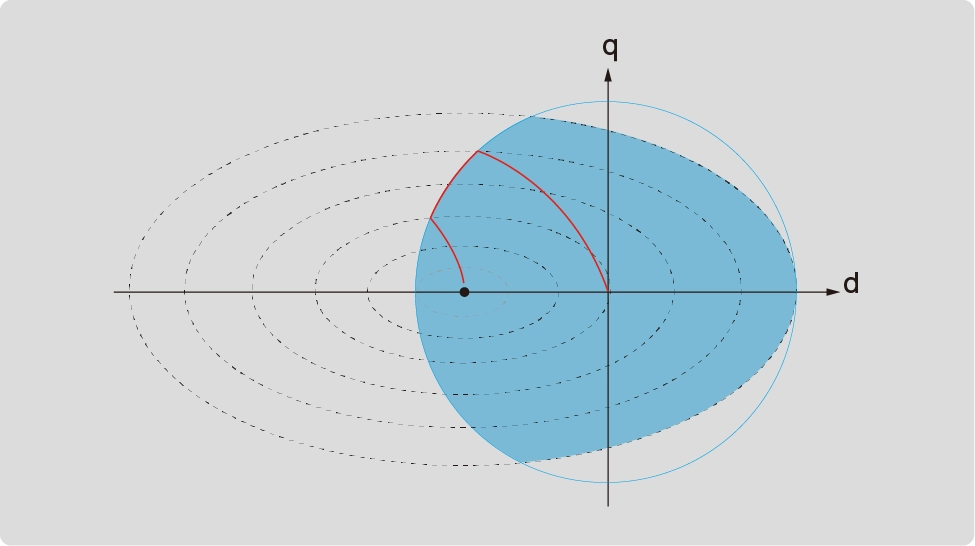

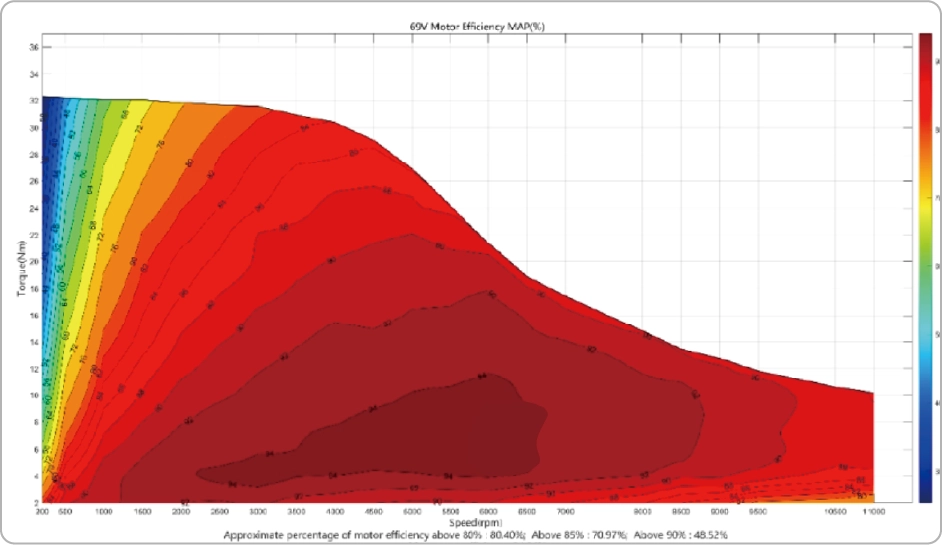

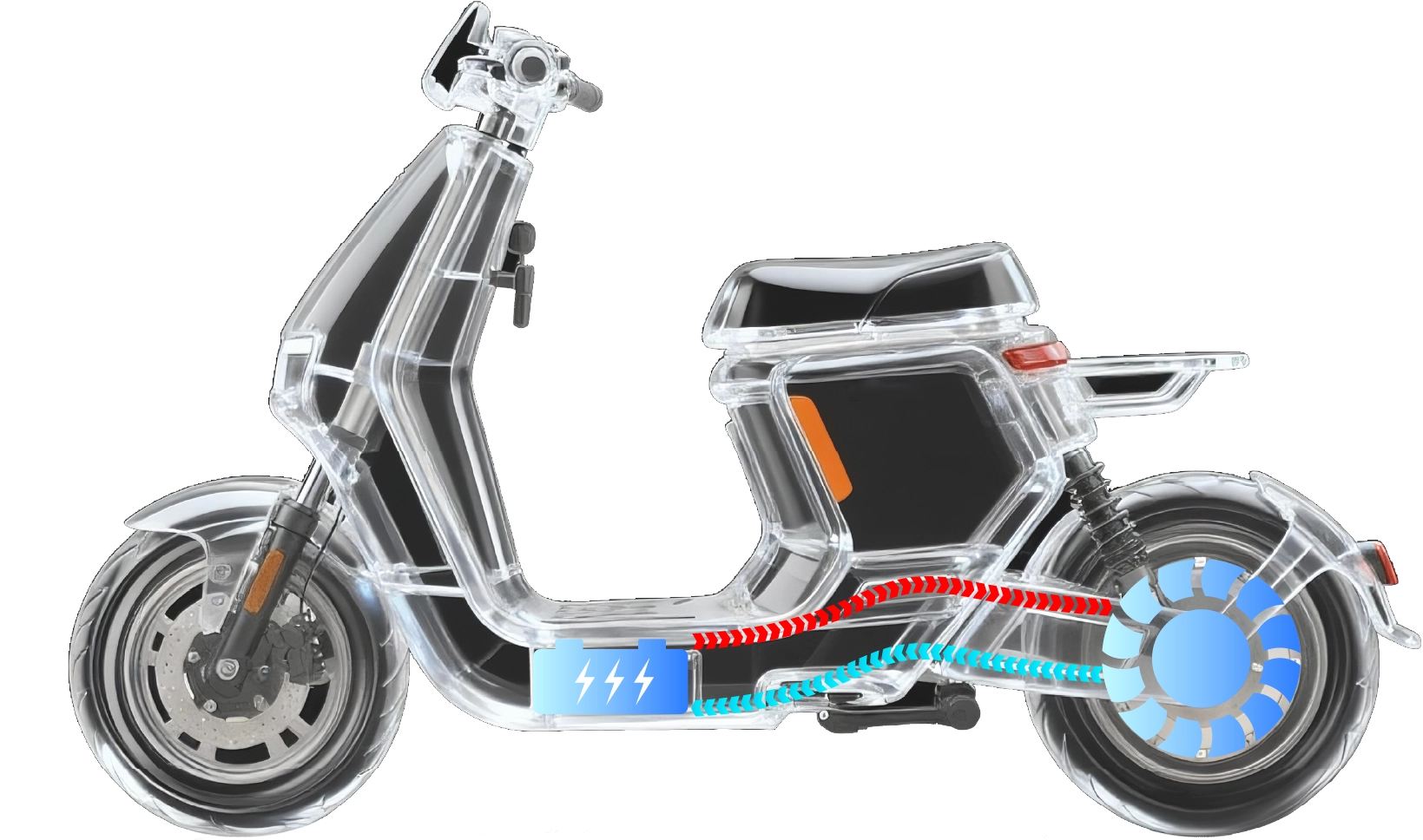

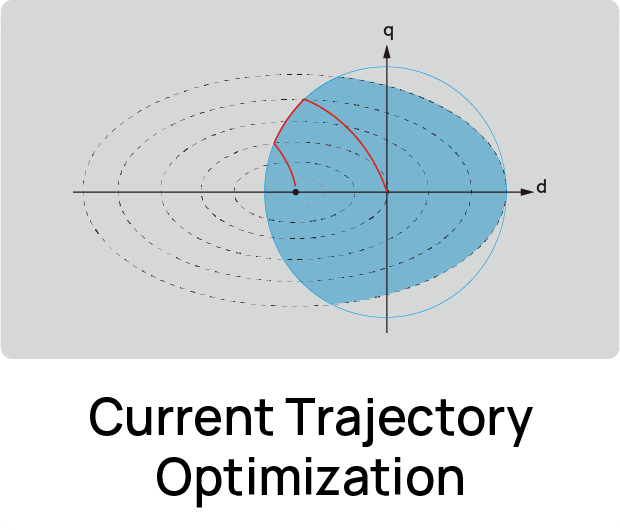

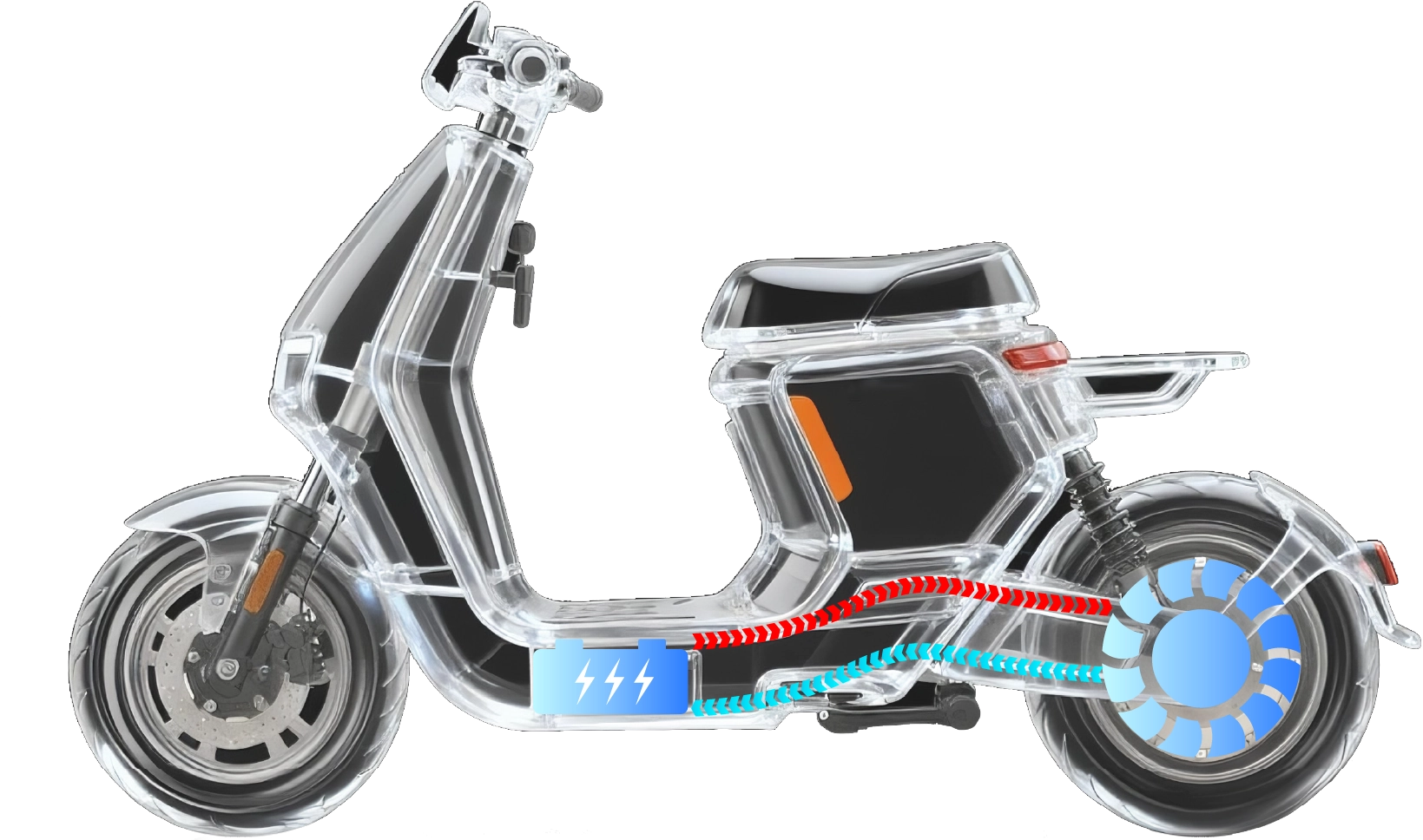

The electric motorcycle motor controller integrates motor control technologies such as MTPA (Maximum Torque per Ampere), FW

(Field Weakening Control), and MTPV (Maximum Torque per Voltage), combined with optimized multi-modulation modes. This

advanced control strategy, embedded in the electric motorcycle ECU, accurately plans the optimal current trajectory. Switching

losses of this electric motorcycle motor controller are 18% lower than those of traditional controllers.

The electric motorcycle controller is also equipped with an EABS (Electronic Assisted Braking System) high-efficiency energy recovery

system. When braking, the kinetic energy recovery rate is increased, allowing excess electrical energy to be recharged to the battery.Test results show that compared with competing electric motorcycle controller models of the same class:

For example, with a basic range of 60km, it can run an extra 3km,

meeting the demand for one short-distance commute.

Prevents performance degradation caused by high

temperatures, ensuring long-term stability of the electric

motorcycle ECU under high-load operation.

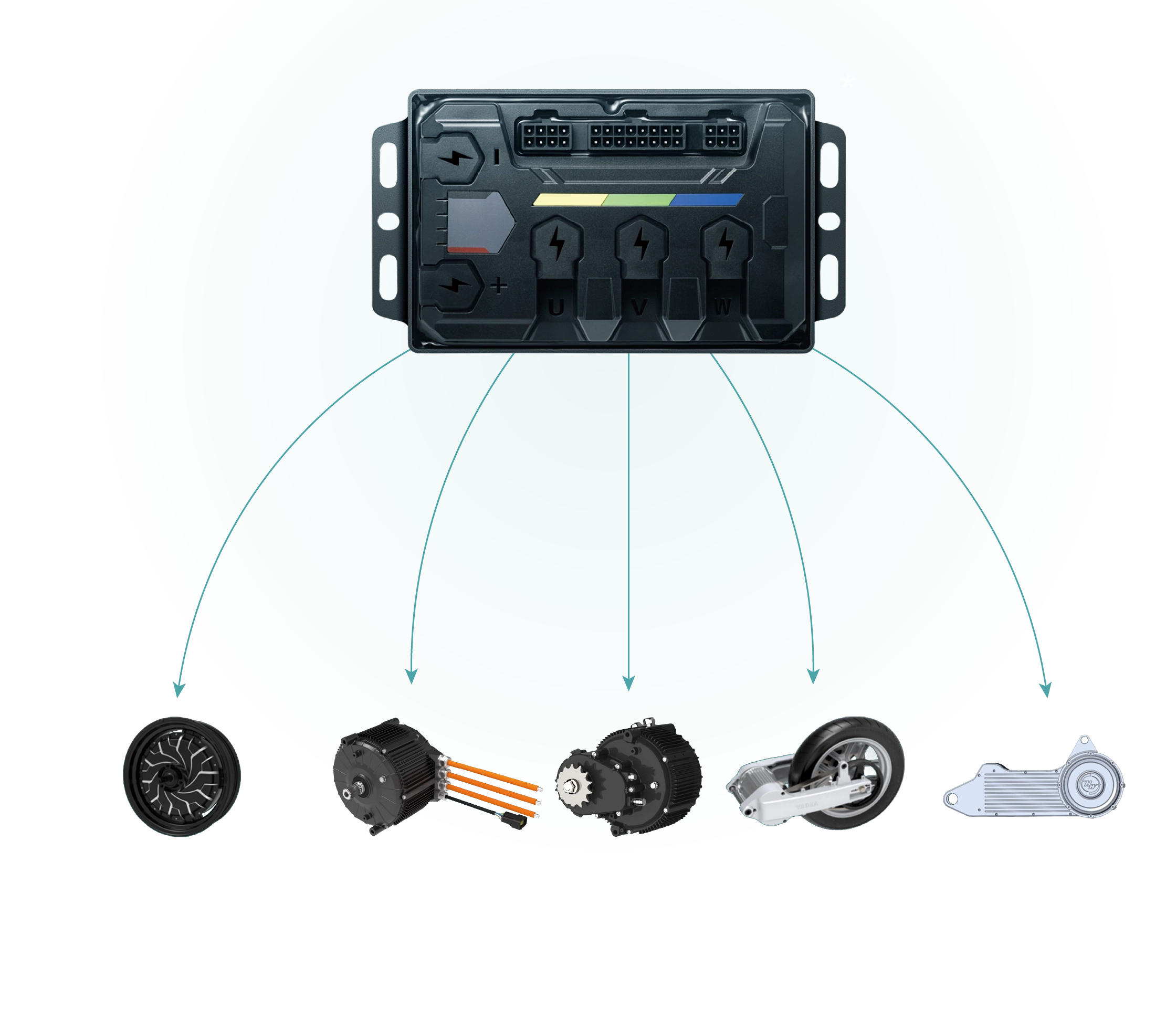

The electric motorcycle controller is built with automatic motor parameter identification and automatic control

parameter auto-tuning functions.

This electric motorcycle ECU can automatically read motor parameters and magnetic encoder/HALL initial angles,

and accurately match torque loop and speed loop parameters.

It is also compatible with over 90% of E-motorcycle instrument clusters and communication protocols on the market.

The motor-controller matching speed is fast, and no professionals are required for repeated manual calibration

during installation and maintenance.

It easily covers R&D needs for multiple vehicle types (basic commuting, performance, and high-end models),

helping manufacturers shorten the adaptation cycle for new vehicle models.

The electric motorcycle controller is built with automatic motor parameter identification and automatic control parameter auto-tuning functions.

This electric motorcycle ECU can automatically read motor parameters and magnetic encoder/HALL initial angles, and accurately match torque loop and speed loop parameters.

It is also compatible with over 90% of E-motorcycle instrument clusters and communication protocols on the market. The motor-controller matching speed is fast, and no professionals are required for repeated manual calibration during installation and maintenance.

It easily covers R&D needs for multiple vehicle types (basic commuting, performance, and high-end models), helping manufacturers shorten the adaptation cycle for new vehicle models.

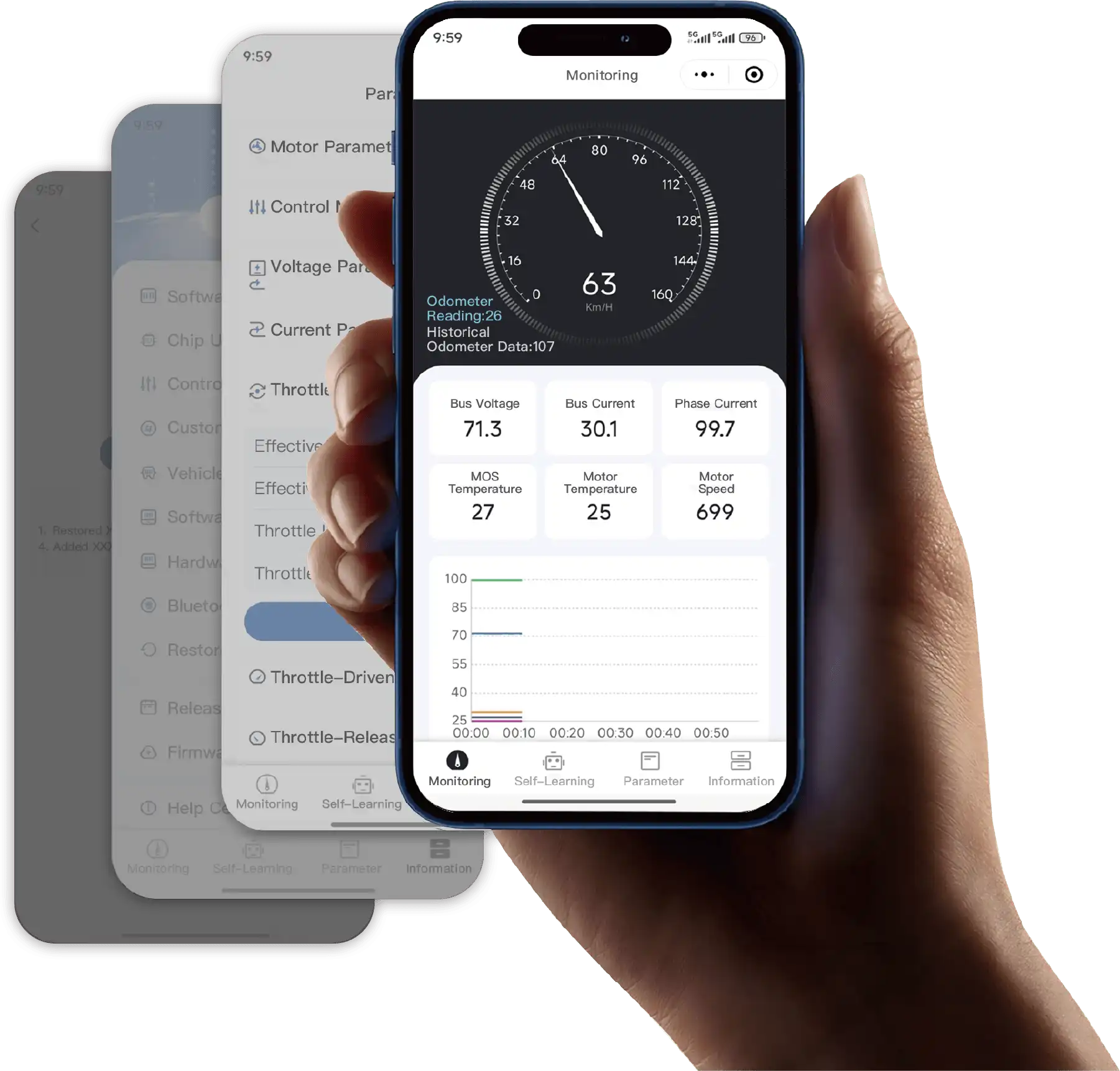

The electric motorcycle motor controller supports remote OTA (Over-the-Air) firmware upgrade, real-time parameter adjustment via mobile APP/PC terminal, and operation log viewing. Functional updates for the electric motorcycle ECU can be completed without disassembling the unit, ensuring continuous performance optimization of the product.

In case of malfunctions, the electric motorcycle controller can identify the root cause within 5 minutes via operation logs, cutting maintenance time by 50% compared to traditional controllers. This not only reduces the inconvenience of users visiting stores for repairs but also helps manufacturers lower after-sales labor and time costs, improving user repurchase rates.

The electric motorcycle ECU’s "One-Click Repair" function provides emergency fault handling: when the vehicle experiences a minor sudden fault, activating this function switches to speed-limited emergency mode, allowing users to ride to a maintenance point and avoiding the trouble of sudden breakdown on the road.

The electric motorcycle controller integrates a TCS (Traction Control System) that improves riding safety on slippery roads. When driving on rainy or muddy roads, TCS can adjust motor output torque in real time, preventing tire spin and slip and reducing the risk of rollover. It is especially tailored to the needs of users in rainy southern areas, supporting safe riding.

When riding long distances, activate the "Cruise Control" function: no need to hold the handlebar to control speed continuously, effectively relieving hand fatigue.When descending slopes, activate the "Hill Descent Control" function: the vehicle runs at a fixed speed, avoiding brake pad overheating caused by frequent braking and balancing riding safety and riding comfort.

When overtaking or climbing steep slopes is needed, pressing the "BOOST" button can instantly boost power output by 20%, easily handling complex road conditions. It meets users' demand for "strong power" and helps manufacturers create differentiated performance selling points.

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.

Our electric motorcycle motor controller is

equipped with position observer and position

sensor safety redundancy technology.

In case of sudden motor sensor failure or poor

wiring connection,

the system can smoothly switch to sensorless

vector control mode,

avoiding risks such as power interruption and

sudden jitter in real time, and maintaining

stable and continuous power output.

Whether a sensor fails unexpectedly during

urban commuting or wiring is affected by

bumps during mountain riding,

this electric motorcycle controller prevents

sudden breakdown on the road and provides

reliable support for users' travel.

The electric motorcycle ECU adopts a dual-layer architecture design for its software, which monitors current, voltage, temperature, speed, and rotor position in real time. Once values exceed limits, it immediately issues an early warning and enters safety mode.

This electric motorcycle controller adopts measures including internal/external clock backup, key signal backup, and core data backup to significantly improve system fault tolerance. Even if components vibrate on bumpy roads or parts wear out in extreme environments, the electric motorcycle motor controller system can still maintain normal overall functionality. It effectively prevents ride interruption caused by sudden malfunctions, creating an "all-weather, all-road" reliable user experience while helping manufacturers reduce after-sales complaints due to electric motorcycle controller faults.

The electric motorcycle controller has passed IP67 waterproof rating testing, -40℃~85℃ high-low temperature cycle testing,

48-hour salt spray testing, and swept-sine/random vibration testing,

complying with national standards GB/T 18387 and GB 34660. Whether for wading rides in the rainy season,

low-temperature startup in the cold winter, or salt spray corrosion environments in coastal areas,

the electric motorcycle controller maintains stable performance.

This helps manufacturers reduce cross-regional after-sales risks and strengthen brand reputation.

The electric motorcycle controller has passed IP67 waterproof rating testing, -40℃~85℃ high-low temperature cycle testing,

48-hour salt spray testing, and swept-sine/random vibration testing,

complying with national standards GB/T 18387 and GB 34660. Whether for wading rides in the rainy season,

low-temperature startup in the cold winter, or salt spray corrosion environments in coastal areas,

the electric motorcycle controller maintains stable performance.

This helps manufacturers reduce cross-regional after-sales risks and strengthen brand reputation.

The electric motorcycle motor controller integrates motor control technologies such as MTPA (Maximum Torque per Ampere), FW

(Field Weakening Control), and MTPV (Maximum Torque per Voltage), combined with optimized multi-modulation modes. This

advanced control strategy, embedded in the electric motorcycle ECU, accurately plans the optimal current trajectory. Switching

losses of this electric motorcycle motor controller are 18% lower than those of traditional controllers.

The electric motorcycle controller is also equipped with an EABS (Electronic Assisted Braking System) high-efficiency energy recovery

system. When braking, the kinetic energy recovery rate is increased, allowing excess electrical energy to be recharged to the battery.Test

results show that compared with competing electric motorcycle controller models of the same class:

For example, with a basic range of 60km, it can

run an extra 3km, meeting the demand for one short-distance

commute.

Prevents performance degradation caused by high

temperatures, ensuring long-term stability of the electric

motorcycle ECU under high-load operation.

The electric motorcycle controller is built with automatic motor parameter identification and automatic control

parameter auto-tuning functions.

This electric motorcycle ECU can automatically read motor parameters and magnetic encoder/HALL initial angles,

and accurately match torque loop and speed loop parameters.

It is also compatible with over 90% of E-motorcycle instrument clusters and communication protocols on the market.

The motor-controller matching speed is fast, and no professionals are required for repeated manual calibration

during installation and maintenance.

It easily covers R&D needs for multiple vehicle types (basic commuting, performance, and high-end models),

helping manufacturers shorten the adaptation cycle for new vehicle models.

The electric motorcycle controller is built with automatic motor parameter identification and automatic control parameter auto-tuning functions.

This electric motorcycle ECU can automatically read motor parameters and magnetic encoder/HALL initial angles,

and accurately match torque loop and speed loop parameters. It is also compatible with over 90% of E-motorcycle instrument clusters and communication protocols on the market. The motor-controller matching speed is fast, and no professionals are required for repeated manual calibration during installation and maintenance.

It easily covers R&D needs for multiple vehicle types (basic commuting, performance, and high-end models), helping manufacturers shorten the adaptation cycle for new vehicle models.

The electric motorcycle motor controller supports remote OTA (Over-the-Air) firmware upgrade, real-time parameter adjustment via mobile APP/PC terminal, and operation log viewing. Functional updates for the electric motorcycle ECU can be completed without disassembling the unit, ensuring continuous performance optimization of the product.

In case of malfunctions, the electric motorcycle controller can identify the root cause within 5 minutes via operation logs, cutting maintenance time by 50% compared to traditional controllers. This not only reduces the inconvenience of users visiting stores for repairs but also helps manufacturers lower after-sales labor and time costs, improving user repurchase rates.

The electric motorcycle ECU’s "One-Click Repair" function provides emergency fault handling: when the vehicle experiences a minor sudden fault, activating this function switches to speed-limited emergency mode, allowing users to ride to a maintenance point and avoiding the trouble of sudden breakdown on the road.

The electric motorcycle controller integrates a TCS (Traction Control System) that improves riding safety on slippery roads. When driving on rainy or muddy roads, TCS can adjust motor output torque in real time, preventing tire spin and slip and reducing the risk of rollover. It is especially tailored to the needs of users in rainy southern areas, supporting safe riding.

When riding long distances, activate the "Cruise Control" function: no need to hold the handlebar to control speed continuously, effectively relieving hand fatigue.When descending slopes, activate the "Hill Descent Control" function: the vehicle runs at a fixed speed, avoiding brake pad overheating caused by frequent braking and balancing riding safety and riding comfort.

When overtaking or climbing steep slopes is needed, pressing the "BOOST" button can instantly boost power output by 20%, easily handling complex road conditions. It meets users' demand for "strong power" and helps manufacturers create differentiated performance selling points.

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.