|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

335V |

MSC 72x25 |

33% |

30509 |

8.9 |

2977.0 |

1124 |

10.2 |

20.70 |

2436.1 |

90.6℃ |

|

35% |

34417 |

10.5 |

3507.5 |

1194 |

9.8 |

23.33 |

2917.0 |

|||

|

37% |

38496 |

12.3 |

4104.4 |

1262 |

9.4 |

26.09 |

3448.1 |

|||

|

39% |

42717 |

14.2 |

4761.5 |

1328 |

9.0 |

28.96 |

4027.0 |

|||

|

42% |

49254 |

17.5 |

5846.3 |

1424 |

8.4 |

33.41 |

4981.4 |

|||

|

45% |

55964 |

21.0 |

7034.1 |

1515 |

8.0 |

37.98 |

6025.0 |

|||

|

49% |

65058 |

26.1 |

8755.8 |

1630 |

7.4 |

44.19 |

7542.6 |

|||

|

51% |

69627 |

28.9 |

9670.6 |

1685 |

7.2 |

47.33 |

8350.0 |

|||

|

54% |

76464 |

33.2 |

11106.8 |

1765 |

6.9 |

52.04 |

9618.1 |

|||

|

57% |

83239 |

37.7 |

12617.1 |

1840 |

6.6 |

56.76 |

10935.1 |

|||

|

60% |

89906 |

42.4 |

14196.4 |

1911 |

6.3 |

61.44 |

12295.3 |

|||

|

63% |

96424 |

47.3 |

15835.4 |

1977 |

6.1 |

66.08 |

13678.7 |

|||

|

66% |

102751 |

52.3 |

17518.4 |

2038 |

5.9 |

70.61 |

15068.4 |

|||

|

69% |

108843 |

57.4 |

19222.2 |

2094 |

5.7 |

75.00 |

16444.2 |

|||

|

72% |

114651 |

62.4 |

20916.0 |

2145 |

5.5 |

79.17 |

17782.8 |

|||

|

75% |

120124 |

67.4 |

22562.7 |

2191 |

5.3 |

83.07 |

19059.1 |

|||

|

78% |

125200 |

72.0 |

24120.4 |

2232 |

5.2 |

86.63 |

20246.6 |

|||

|

81% |

129809 |

76.3 |

25546.1 |

2267 |

5.1 |

89.77 |

21310.4 |

|||

|

84% |

133869 |

80.0 |

26798.1 |

2297 |

5.0 |

92.45 |

22235.8 |

|||

|

87% |

137287 |

83.1 |

27838.9 |

2323 |

4.9 |

94.61 |

23013.2 |

|||

|

100% |

138264 |

84.0 |

28133.1 |

2330 |

4.9 |

95.21 |

23229.1 |

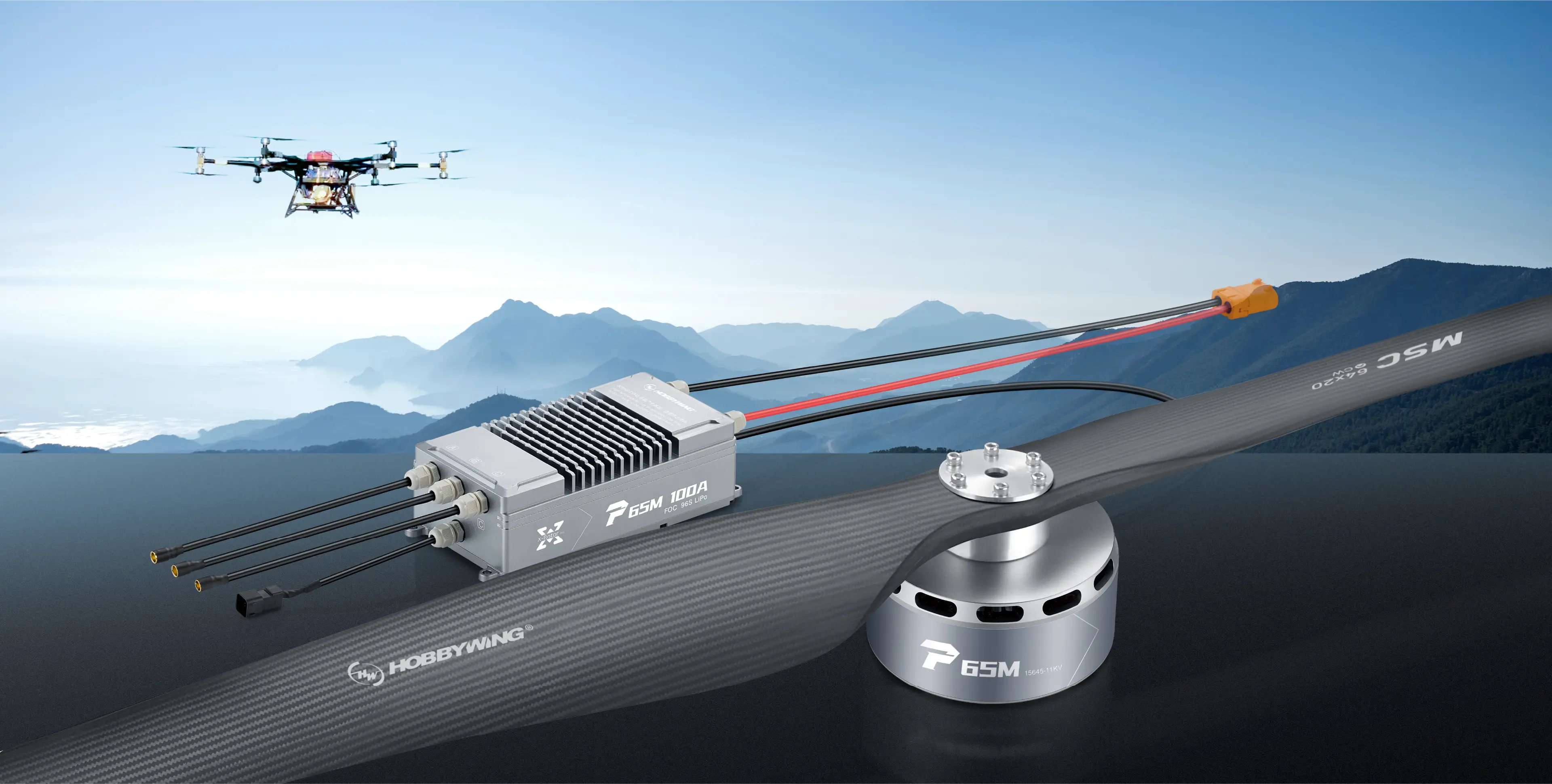

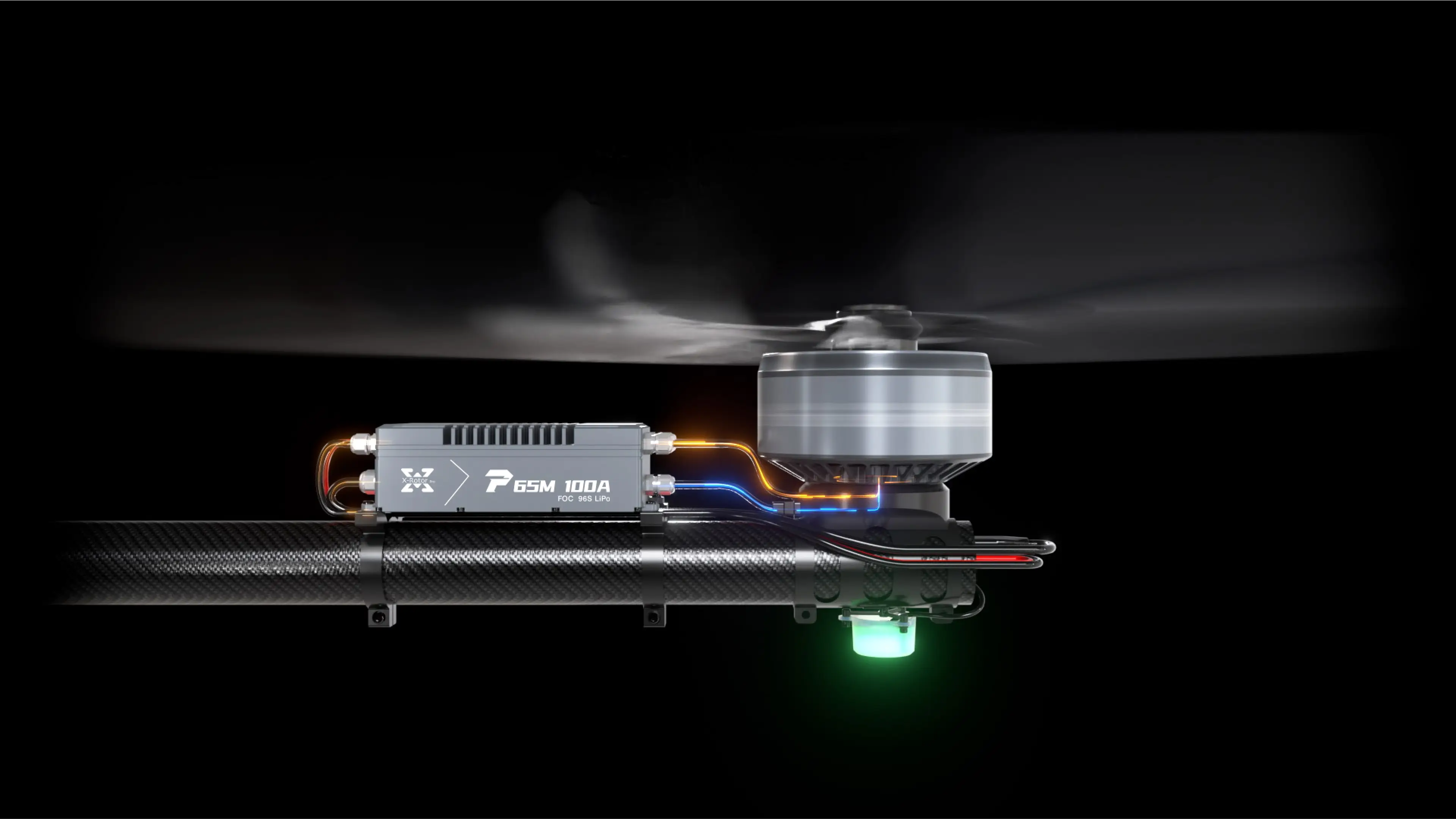

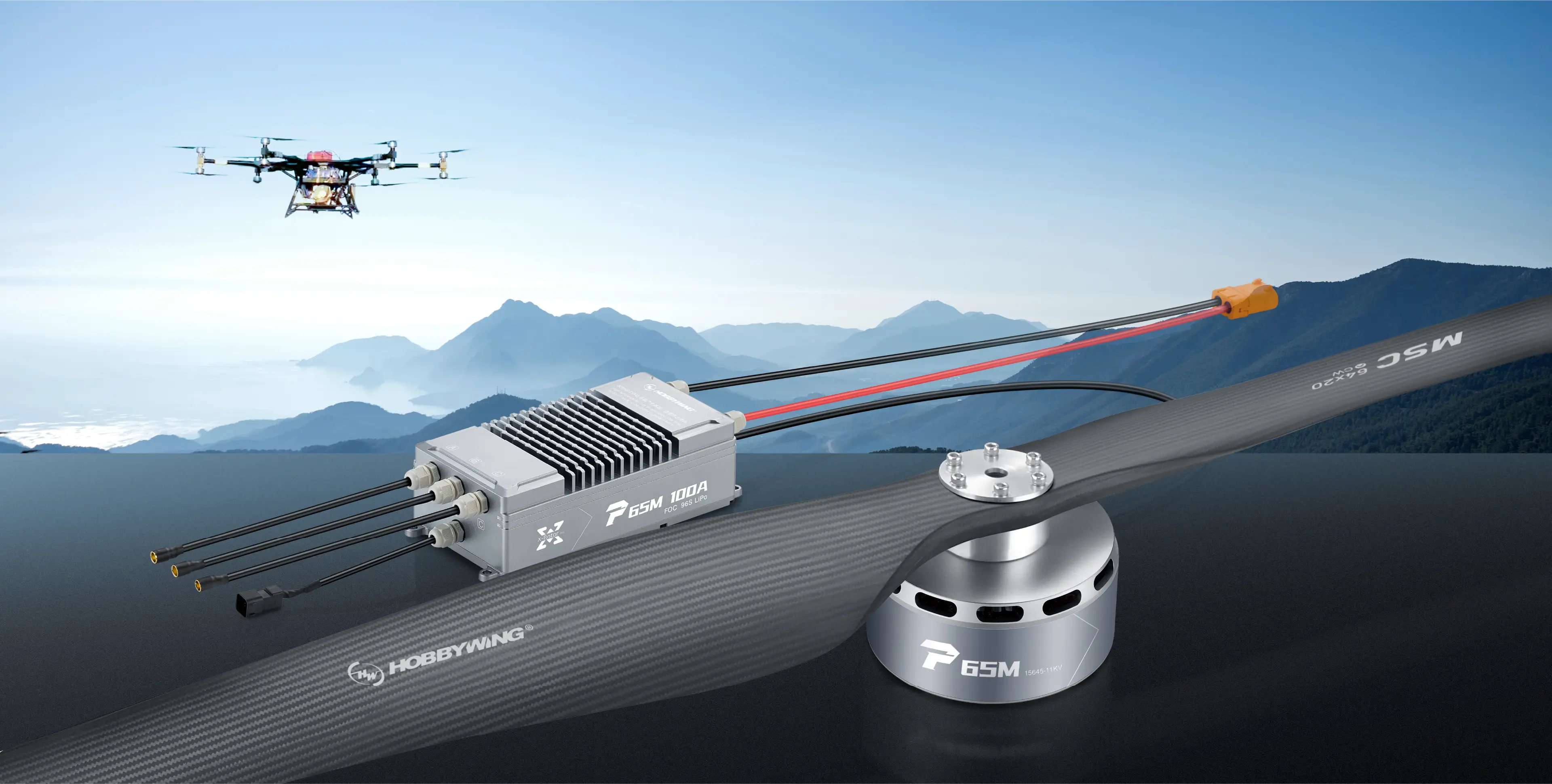

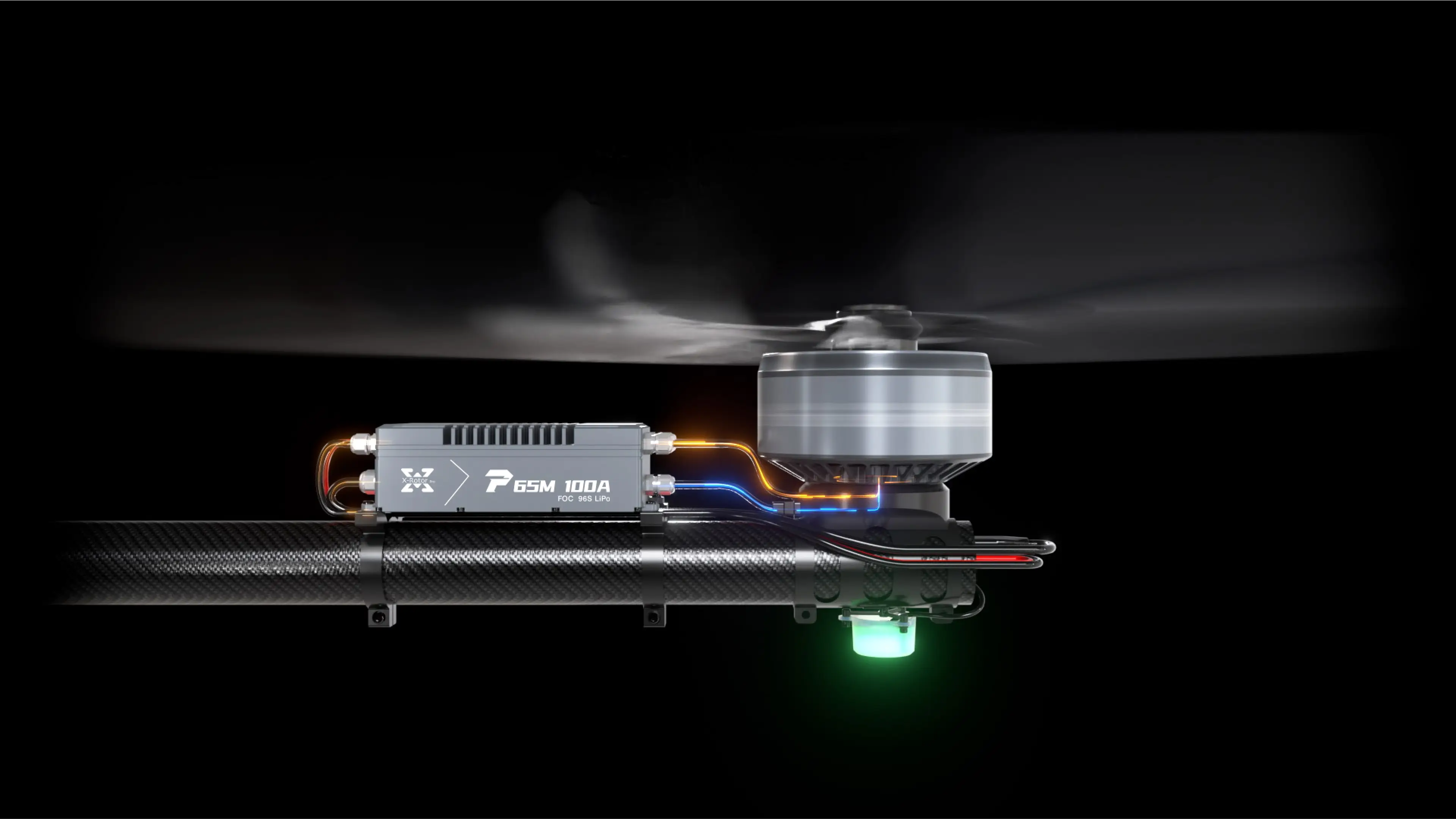

Propulsion System

Car Standards

- Software

- Adopts a rigorous modular design.

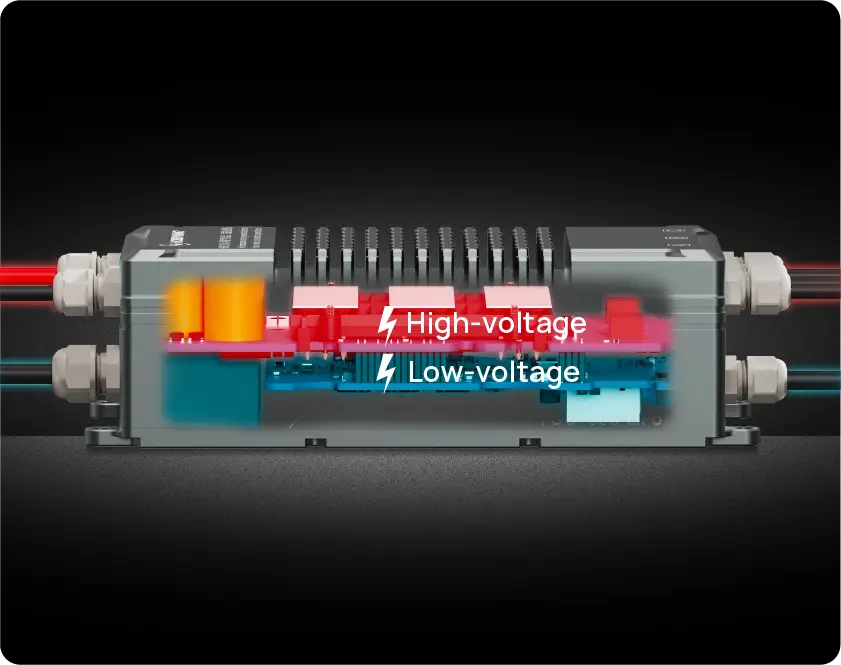

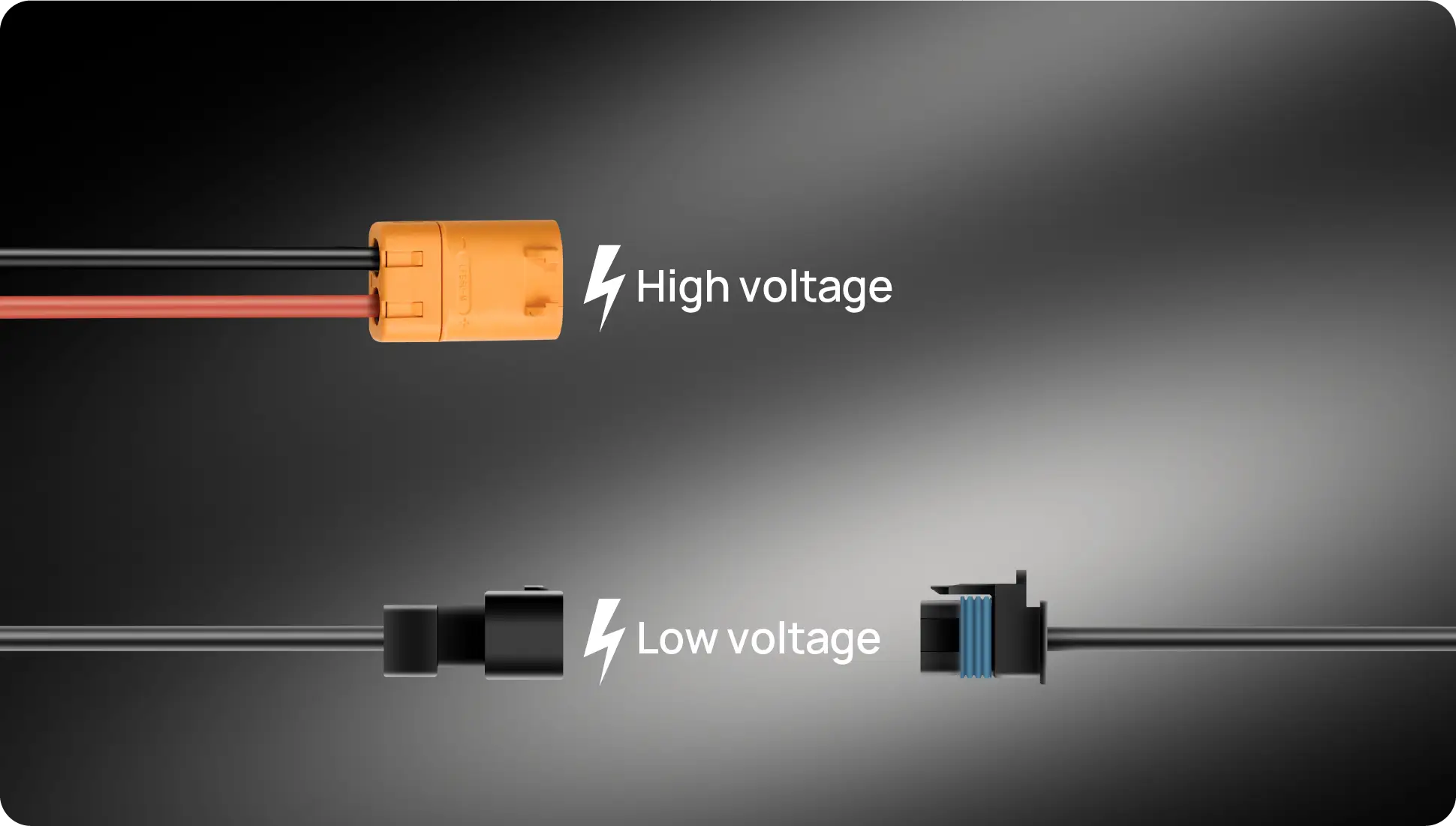

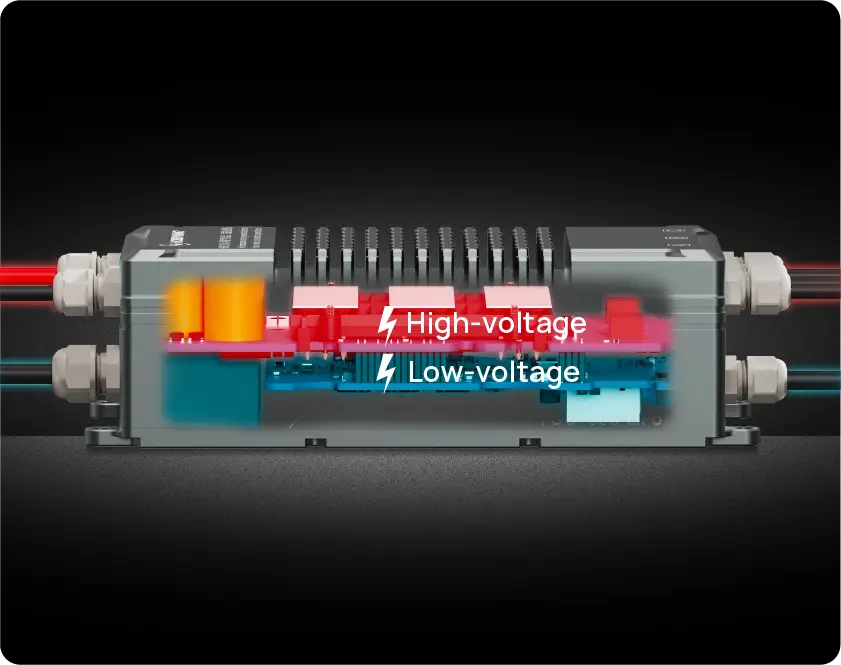

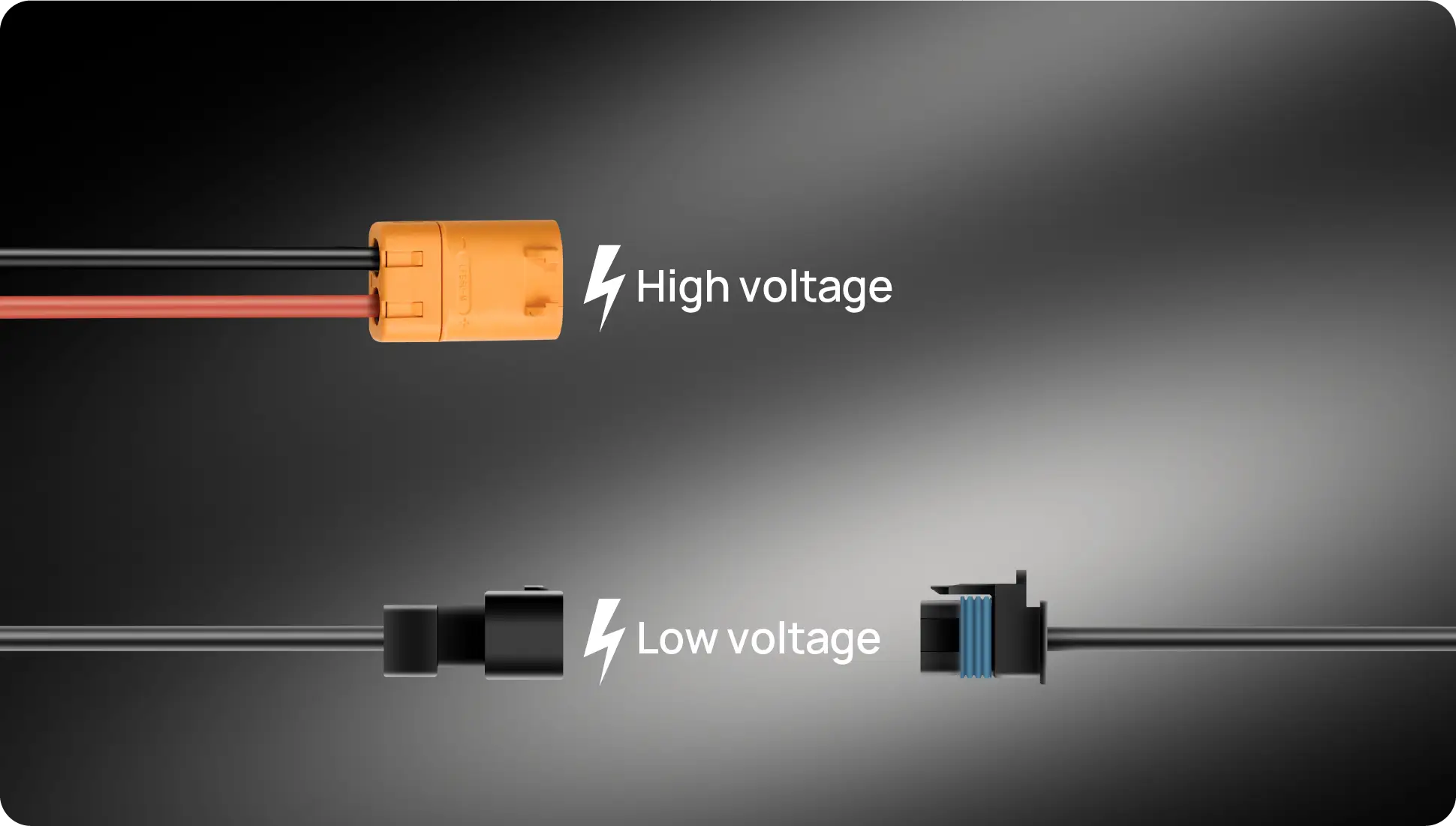

- Fully Isolated Architecture with Protective Earthing

- High-voltage power circuits, low-voltage signal circuits,

- and protective earthing (PE) are completelyisolated,

- delivering reliable data transmission,

- stable system performance,

- and superior safety for operators and equipment alike.

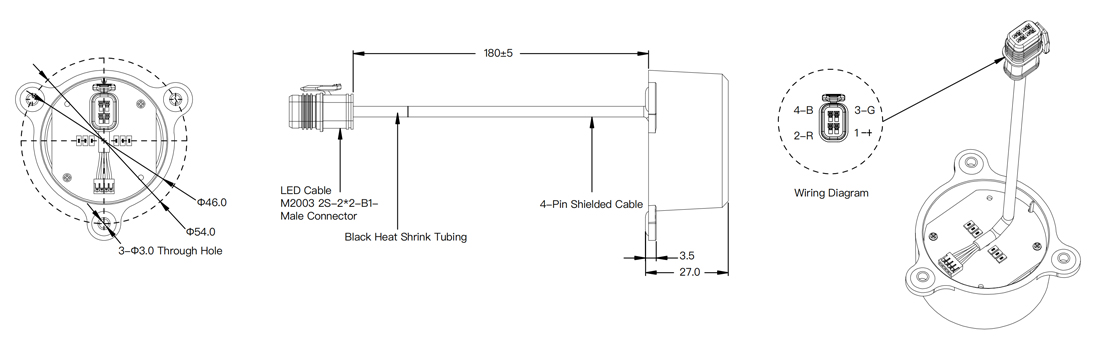

Position Sensor

Real-time RPM acquisition via dual channels,

engineered to meet current airworthiness certification standards

while preparing for future regulatory evolution.

With High Reliability

With High Reliability

.webp)

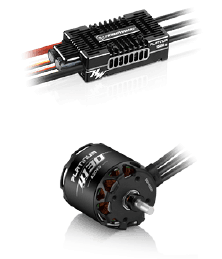

- High-Temperature ESC with Automotive Components

- The Electric Speed Controller (ESC) uses premium automotive-grade

- components designed for elevated temperature resistance.

- High-Reliability Motor Design

- Built with high-temperature resistant materials and

- equipped with a knurled shaft + dual-screw anti-loosening system for secure.

- long-term performance.

- Propeller

- The propeller adopts carbon fiber molding process.

- Vibration-Resistant Automotive Connectors

- Constructed from automotive-grade materials,

- both high- and low-voltage connectors incorporate fool-proof alignment,

- poor-contact prevention, and superior vibration resistance

- for rock-solid system connectivityand extended service life.

Swipe left to view all

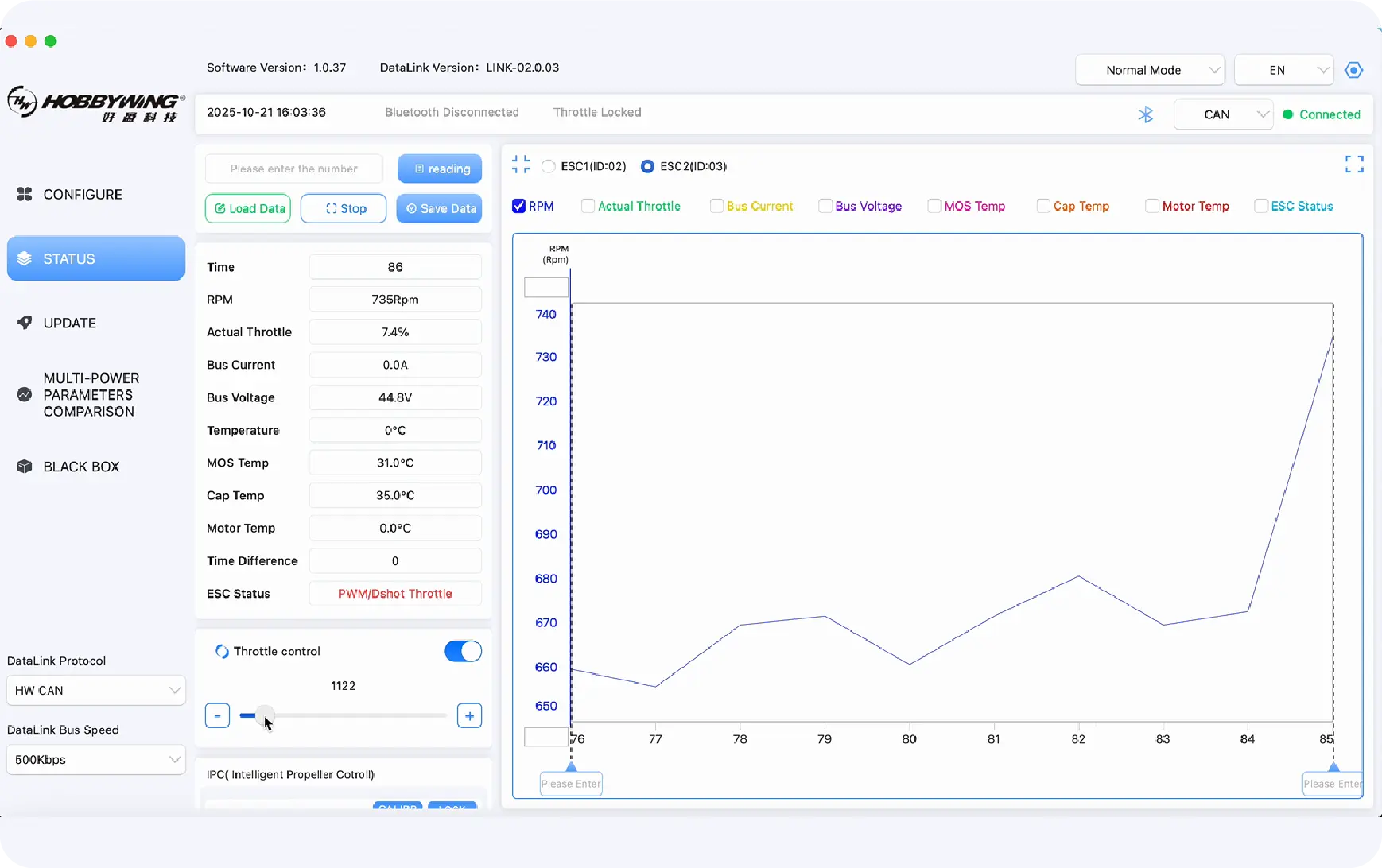

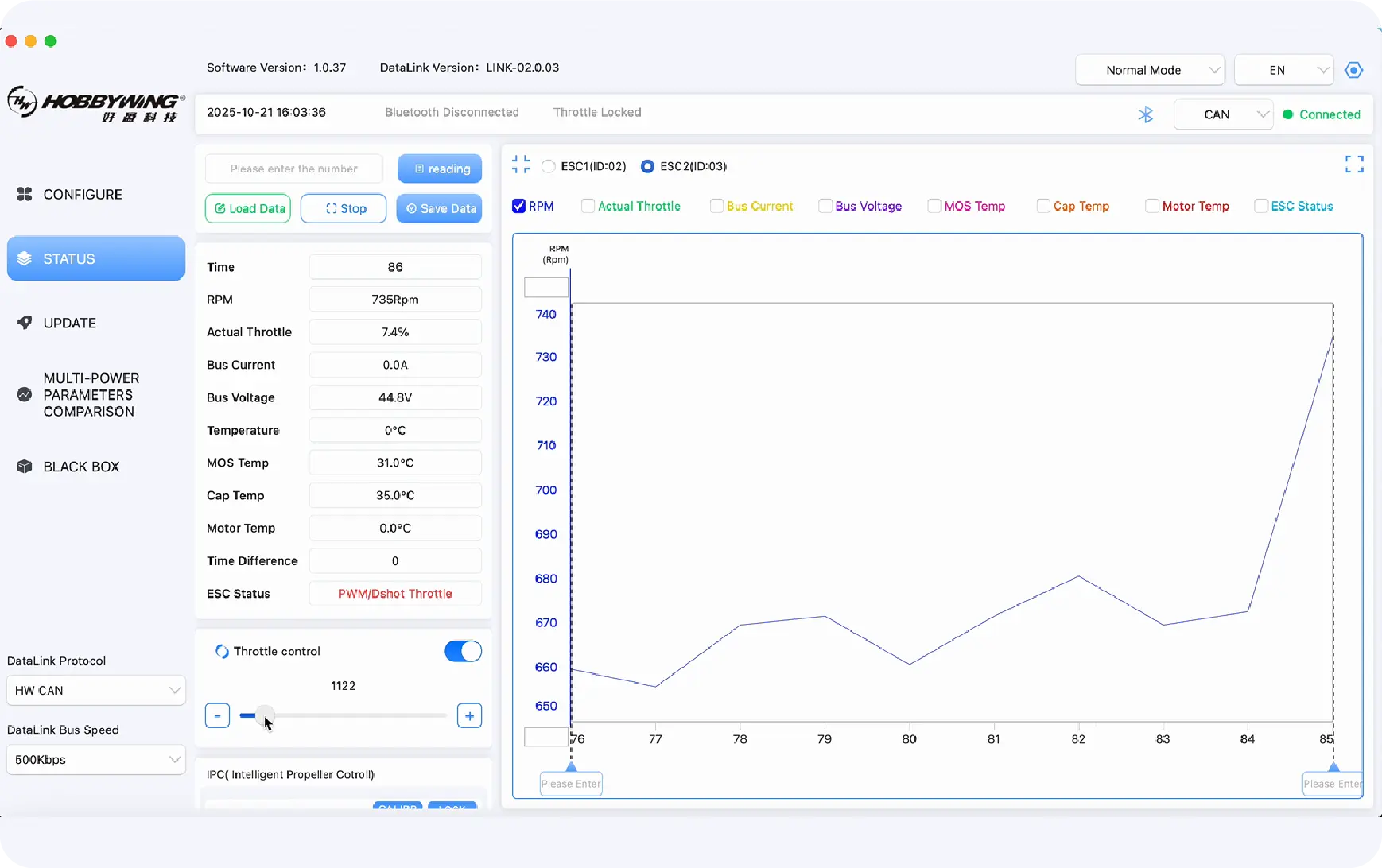

Swipe left to view alland Triple Throttle Control Modes

Triple throttle control modes are as follows:

1

- PWM+CAN digital throttle

- is the default configuration

2

- PWM+RS485

- is optional

3

- CAN+RS485

- is optional

data exchange and ongoing monitoring ofessential parameters:

(RPM,throttle position, current, voltage, and temperature.)

The resultis rapid analytics, swift corrective action.

and substantiallyelevated fight safety.

for Superior Safety

Direct RPM acquisition using a physical sensor for precise,

dependable motor control.

RPM signal intelligently calculated through software algorithms,

eliminating the need for a physical sensor.

Extensively validated with over

1000 hours of aging testing,

guaranteeing maintenance-free

reliability for the entire service life.

developed and designed by HOBBYWING,

ensuring meticulous attention to every detail

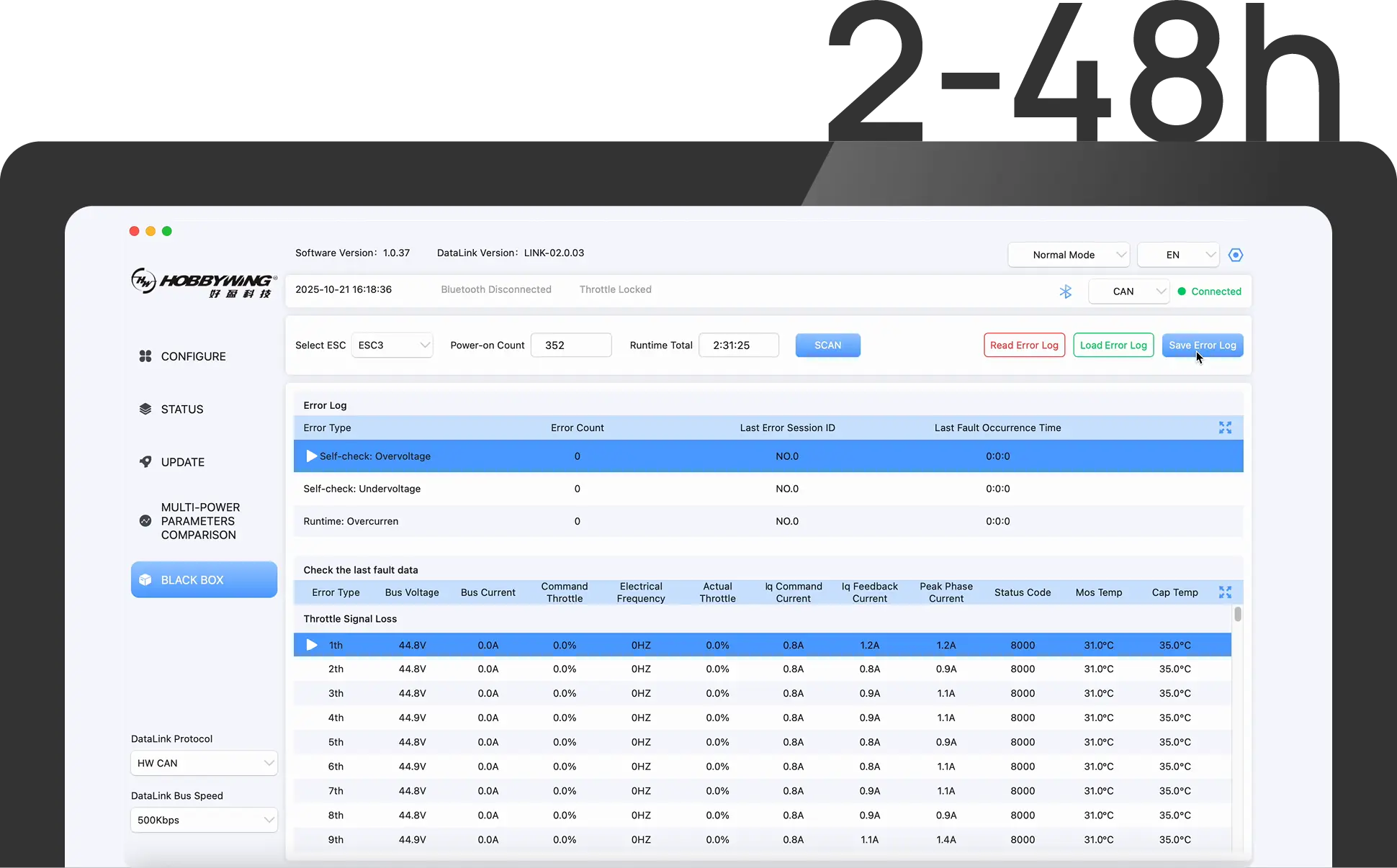

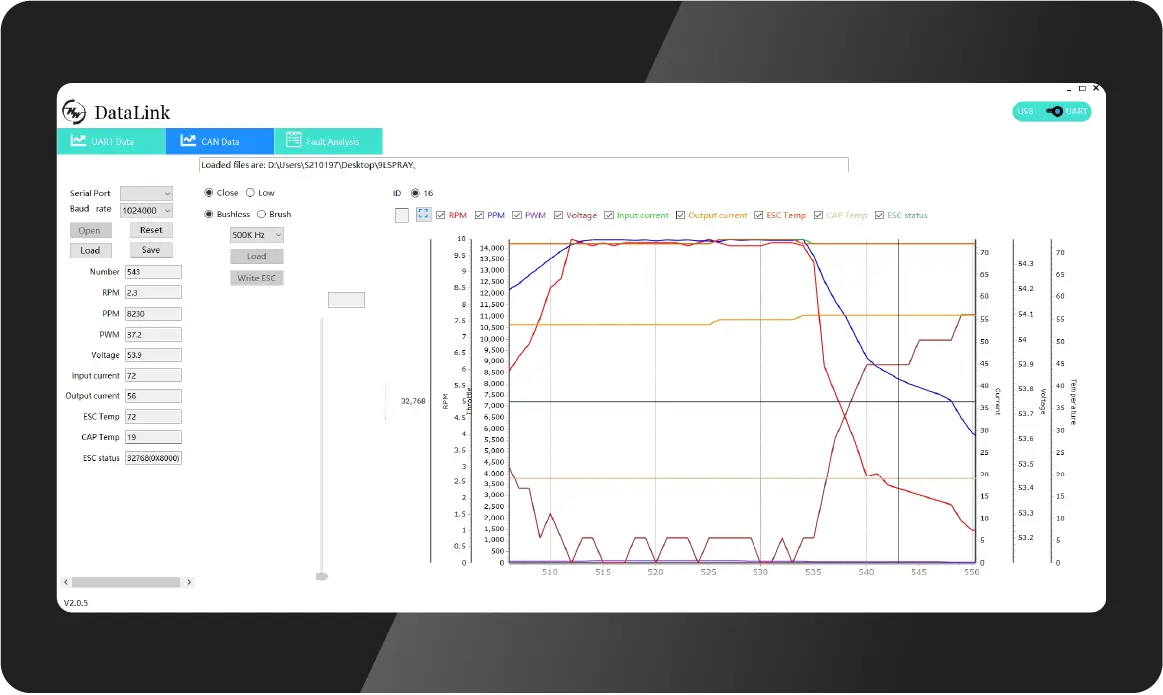

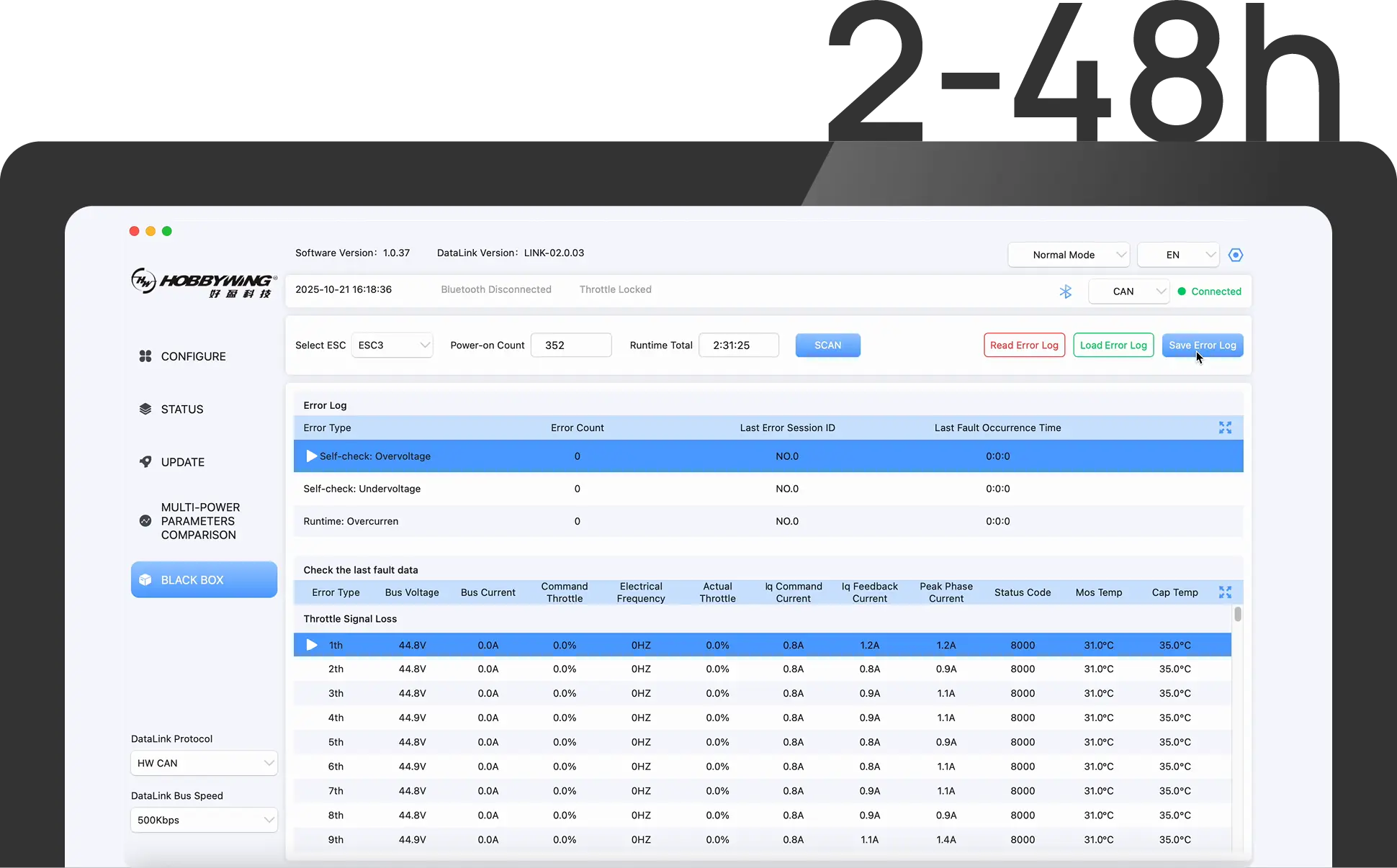

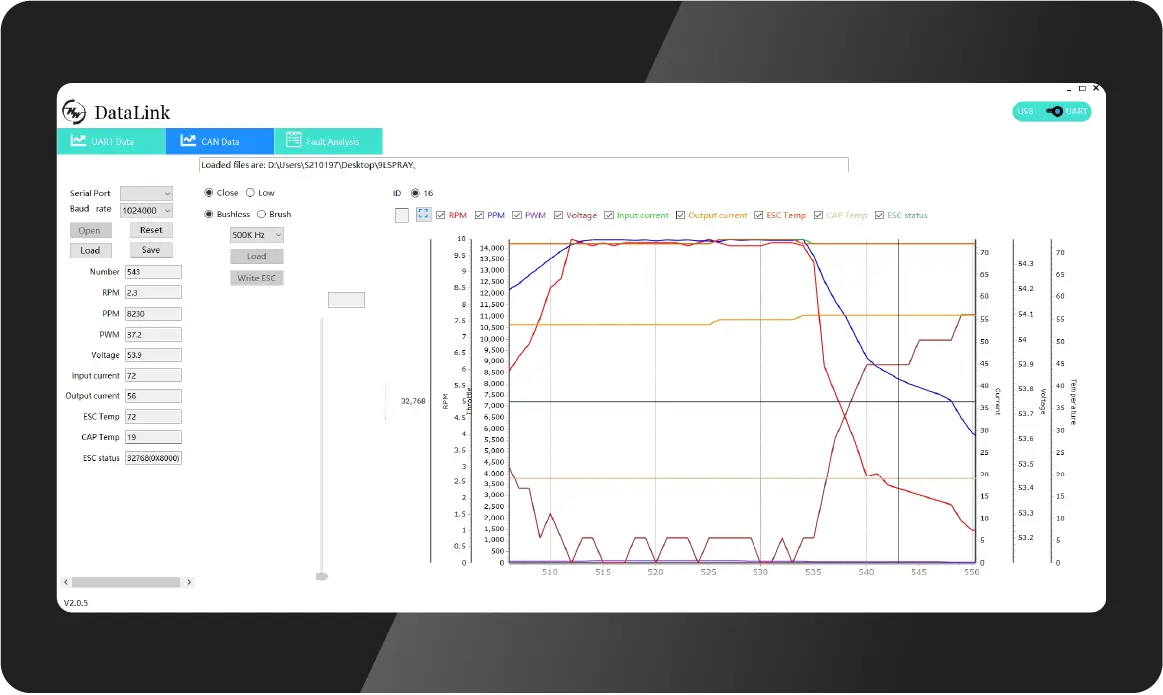

millisecond-level recording of real-time operational data,

enabling comprehensive traceability analysis

The fault storage function records operational fault codes during operation,

enabling precise root cause tracing.

The system continuously records the drone's operational data for 2-48 hours,

facilitating comprehensive post-flight data analysis.

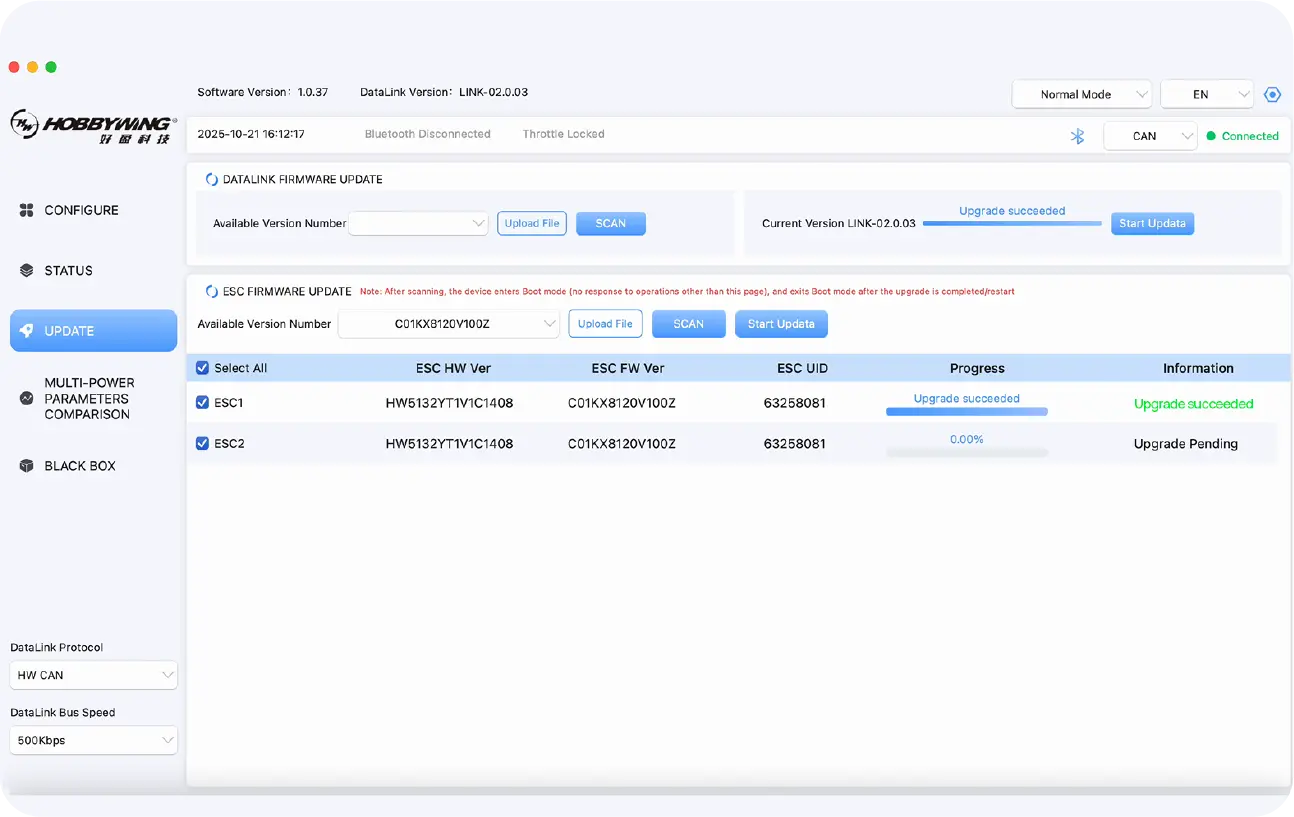

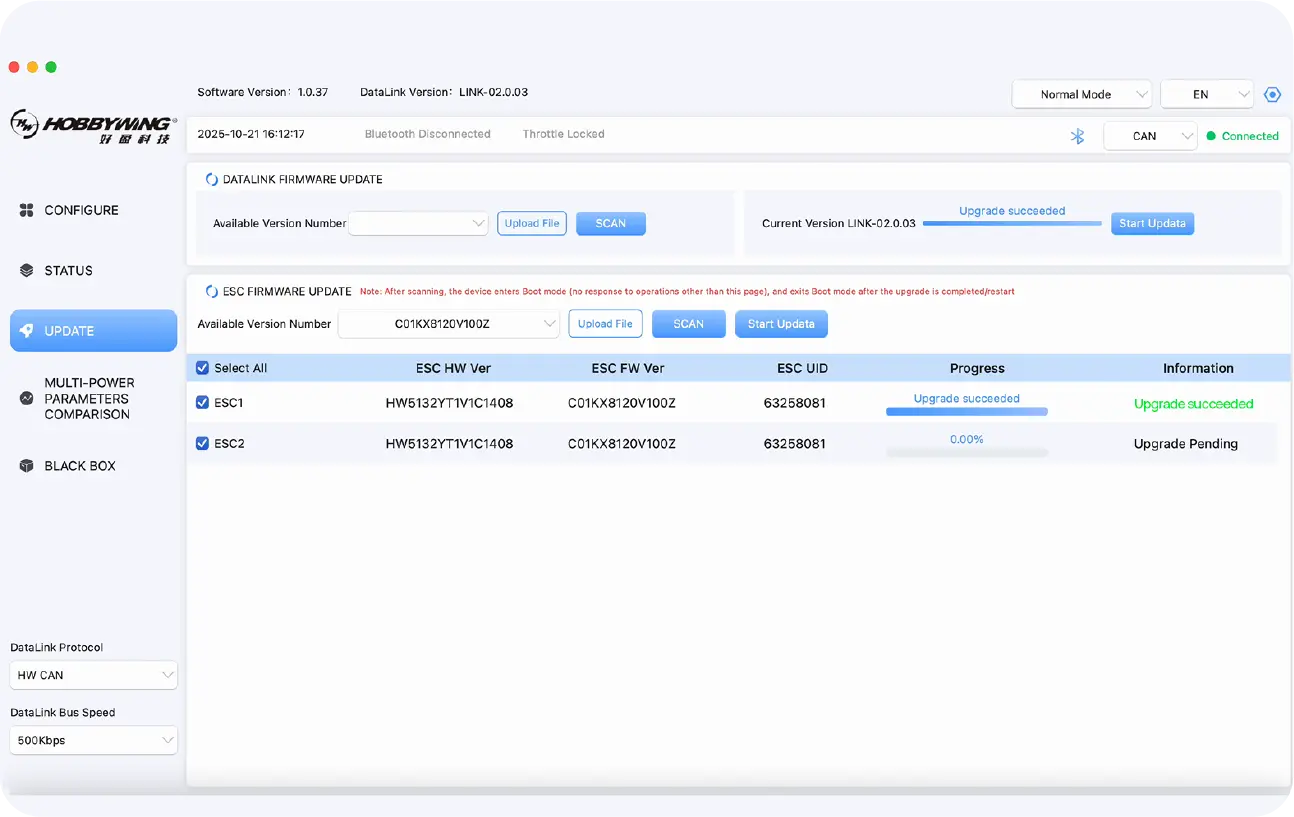

Firmware OTA Updates

With HOBBYWING’s proprietary host computer software (DataLink),

users can adjust drive parameters, motor direction,

and LED color (default green) effortlessly to optimize flight performance

and upgrade the latest firmware.

Compatibility

Compatible with mainstream flight controller systems such as

ArduPilot open-source ecosystem, VK, Byaero and Jiyi, supports CAN communication,

and builds an intelligent flight ecosystem.

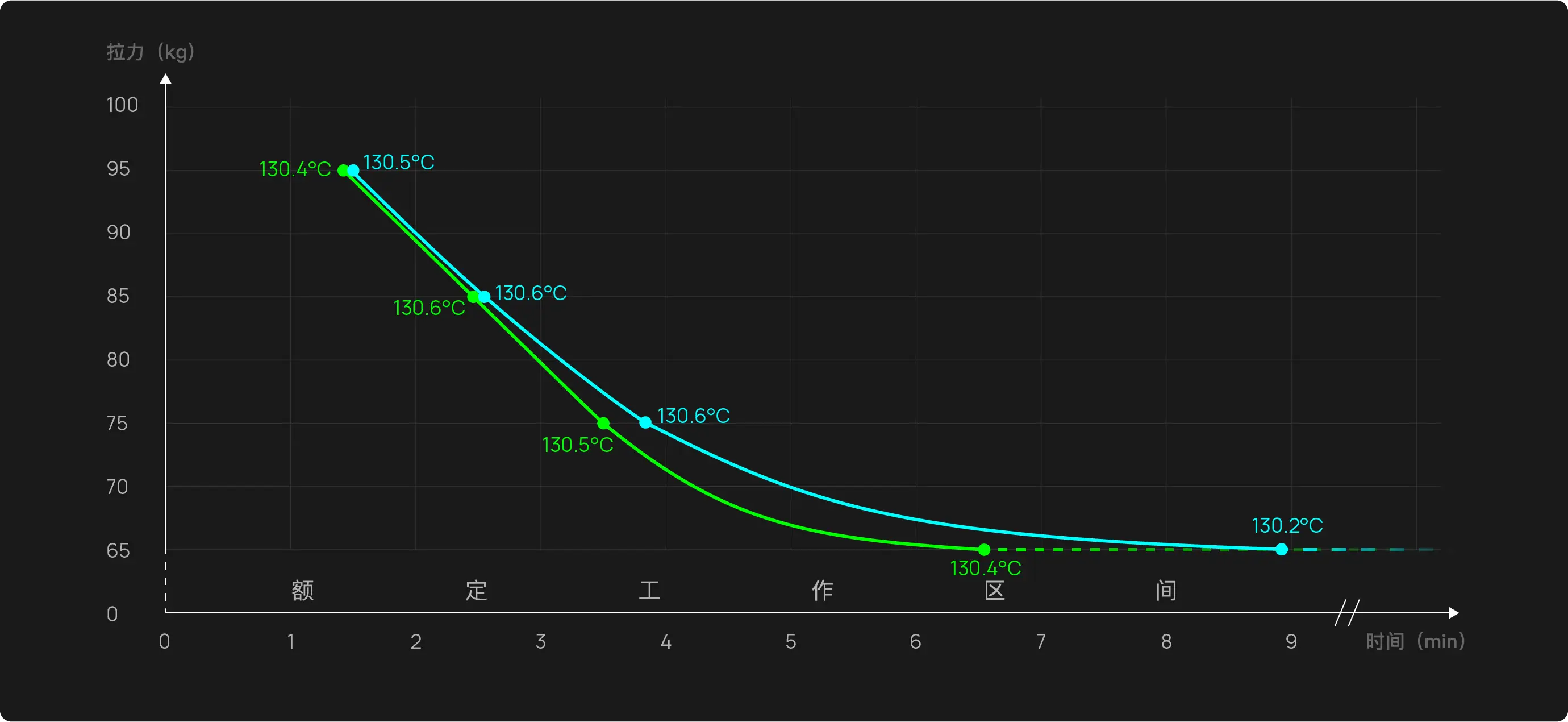

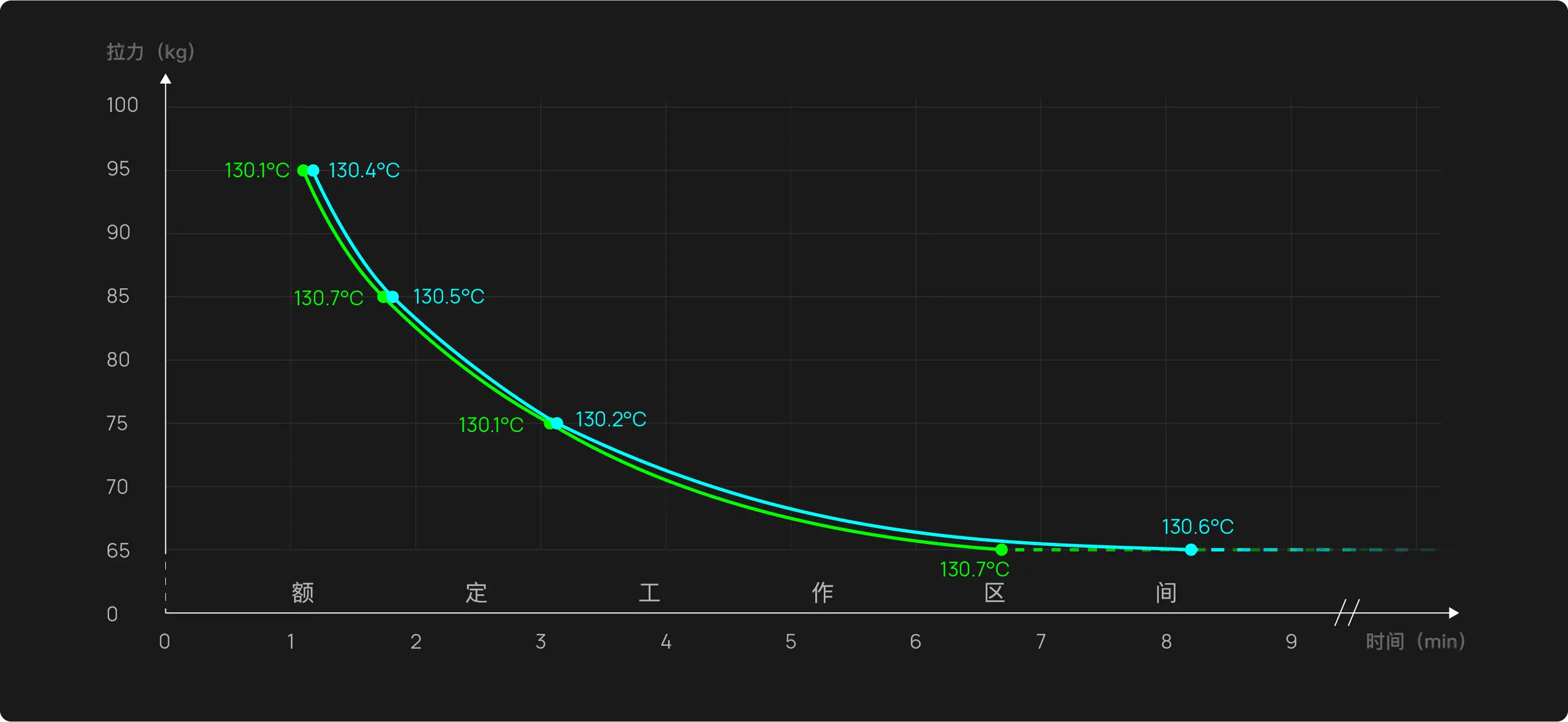

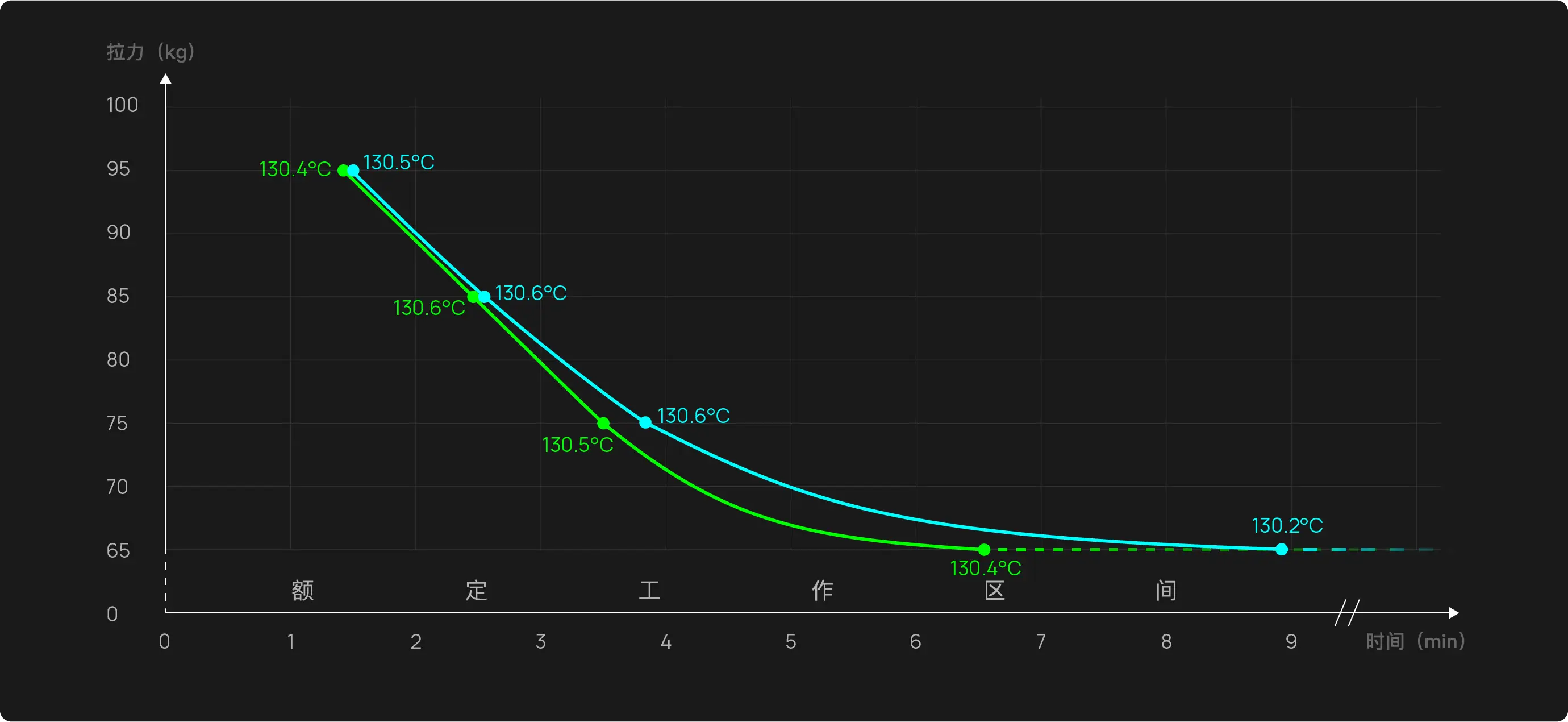

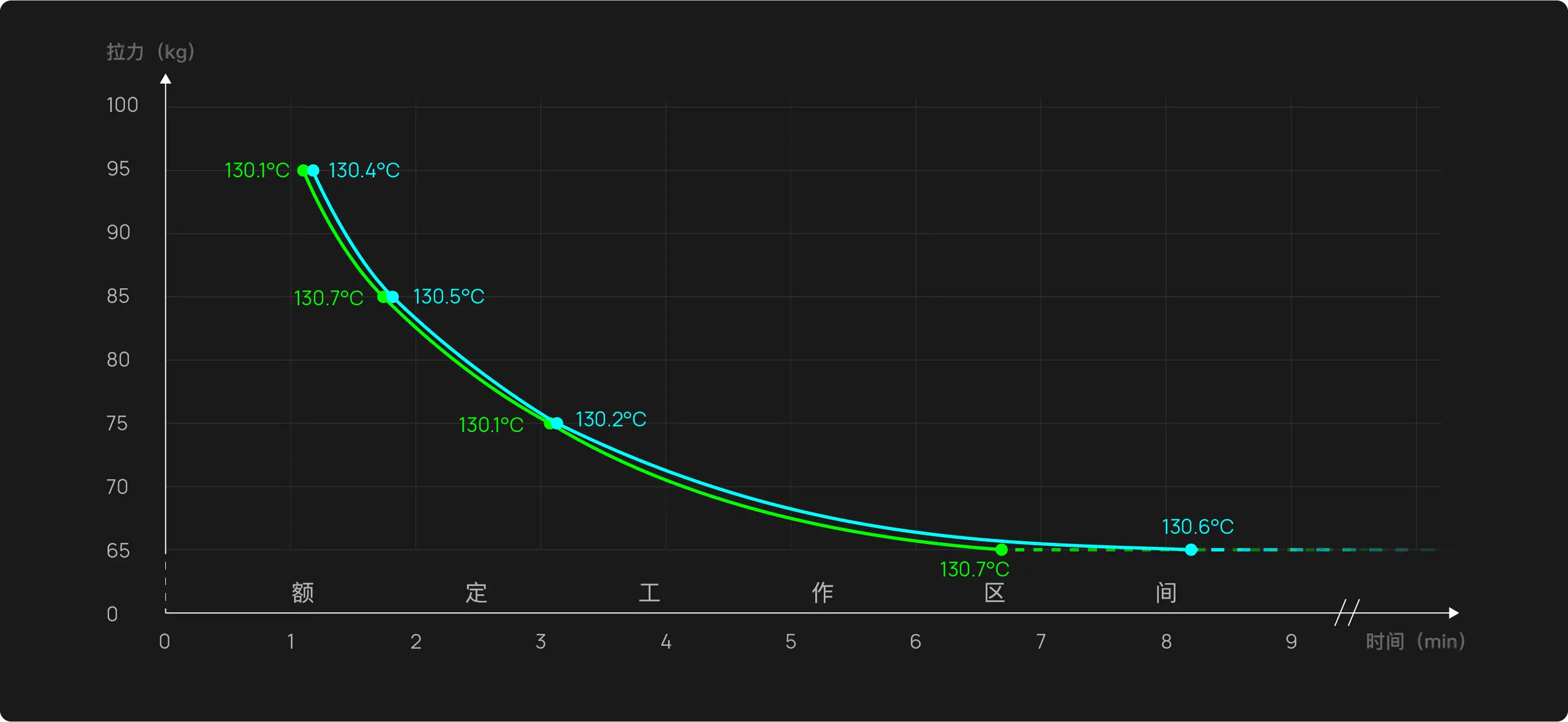

Feedback of Coil Temperature

Monitor the temperature rise data during motor operation in real time

and take timely countermeasures to ensure flight safety.

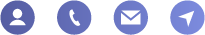

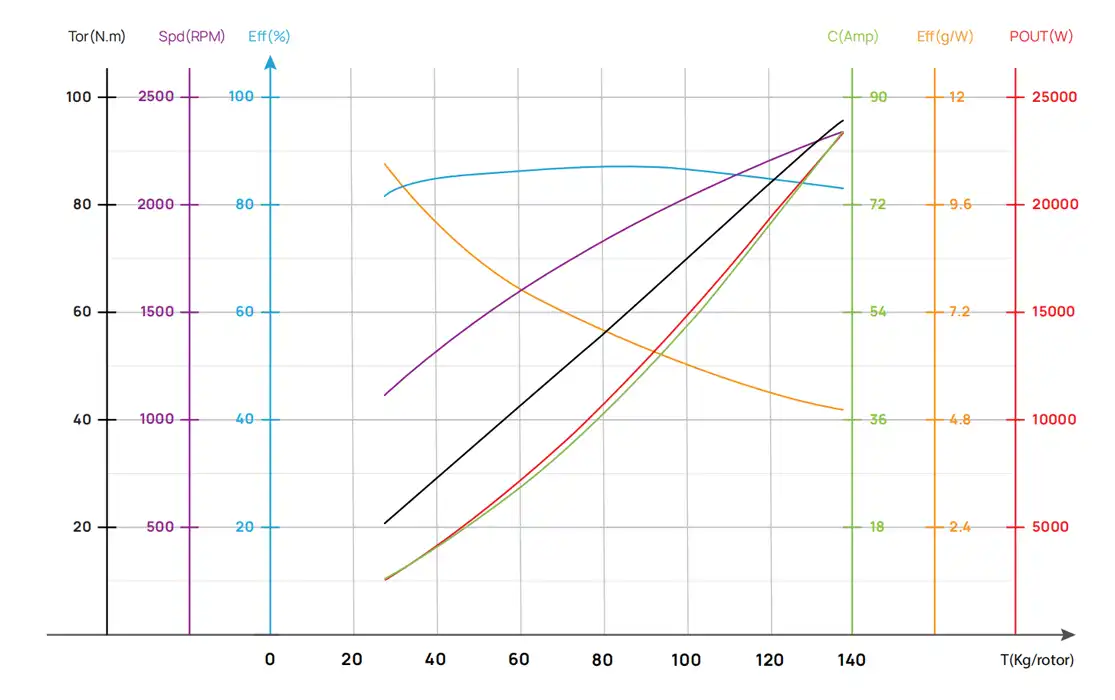

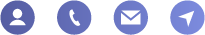

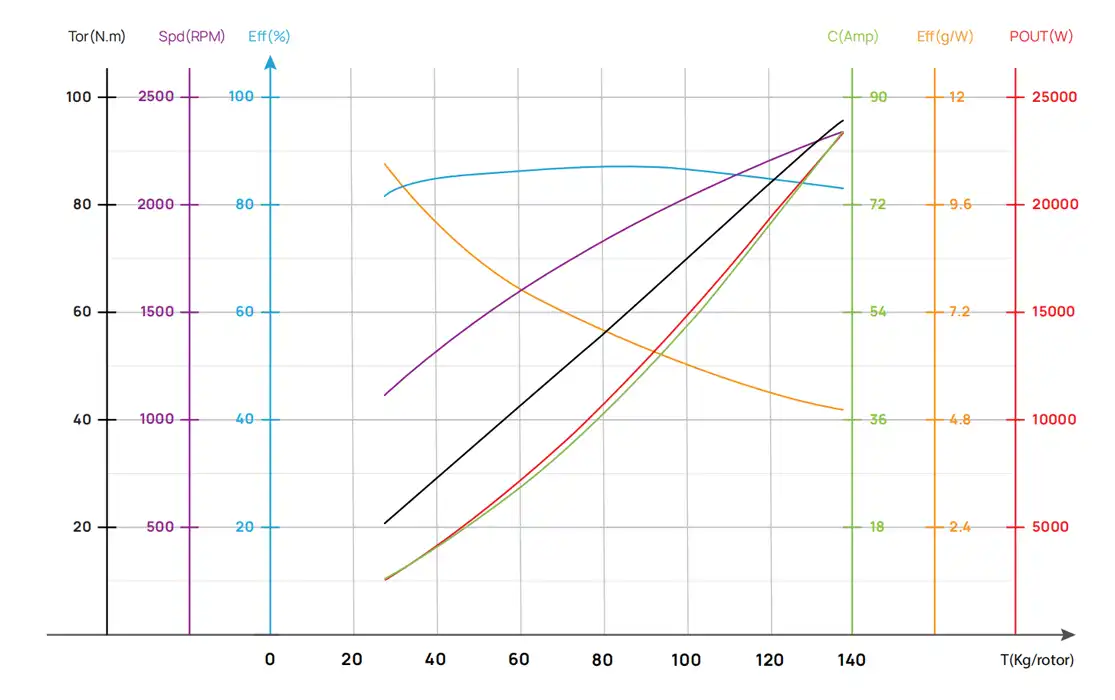

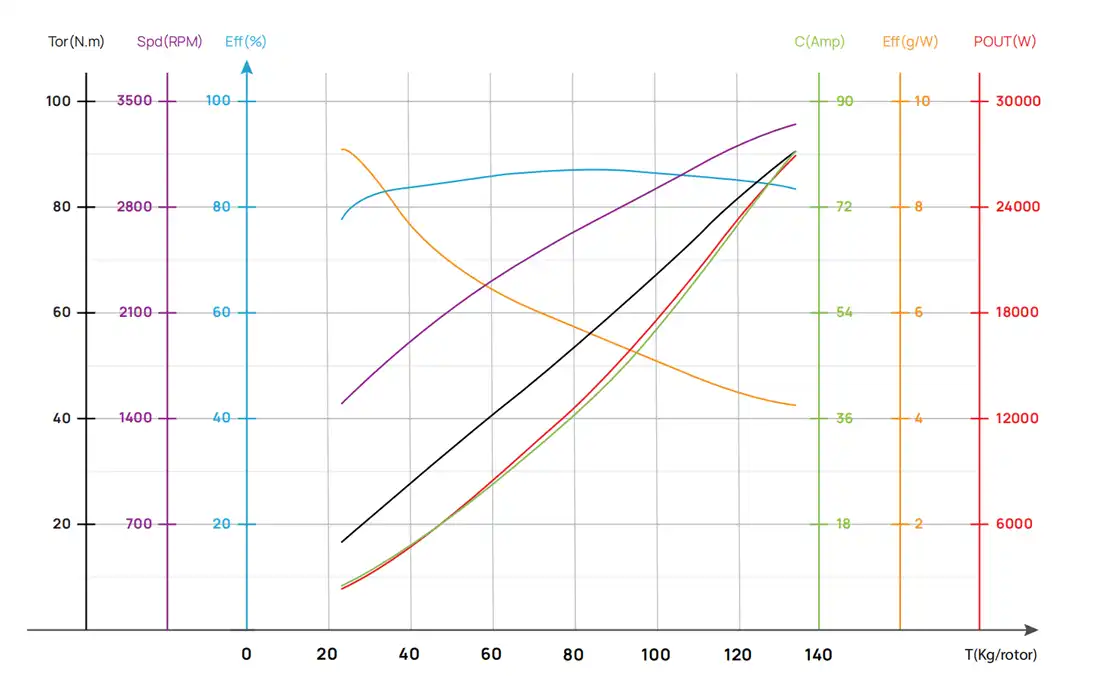

- *The above data were measured at room temperature (25℃) and sea level, and the motor and ESC were under the condition of good heat dissipation.

- The abscissa represents the maximum safe operating time at each overload point. In actual flight, if the propulsion system exceeds this time,

- there is a high probability of irreversible failure. But for flight safety, the propulsion system will not automatically shut down.

- *The above data were measured at room temperature (25℃) and sea level, and the motor and ESC were under the condition of good heat dissipation.

- The abscissa represents the maximum safe operating time at each overload point. In actual flight, if the propulsion system exceeds this time,

- there is a high probability of irreversible failure. But for flight safety, the propulsion system will not automatically shut down.

-

-

Thank you for your interest in HOBBYWING propulsion systems! For customized solutions,

please provide your contact information and technical requirements,

and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

-

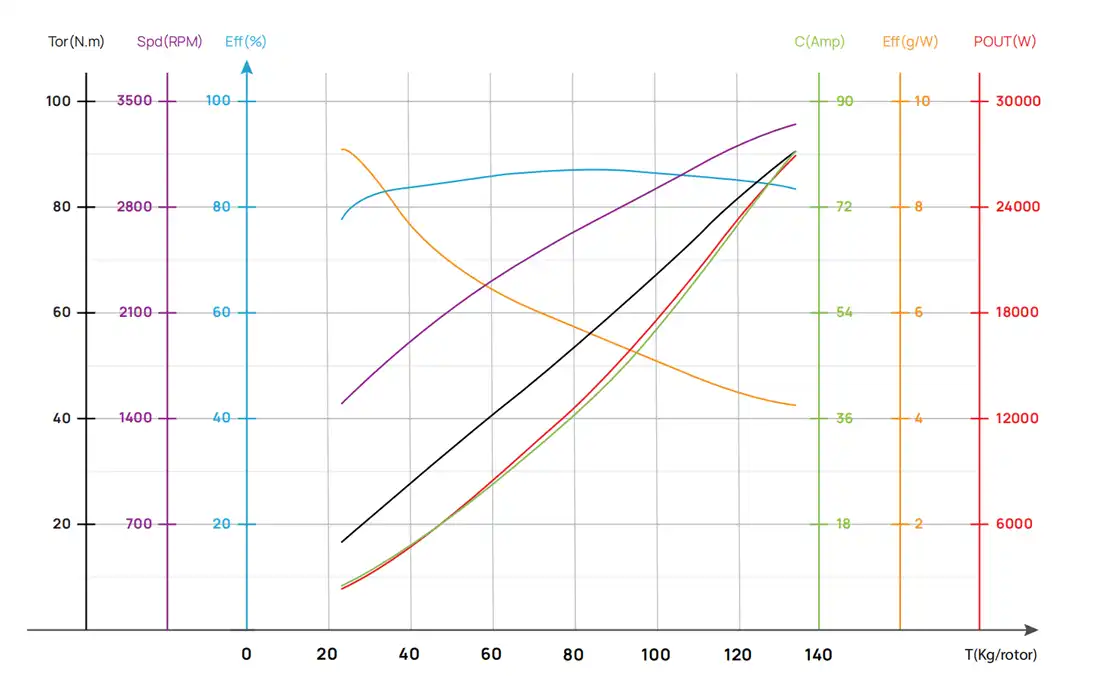

- Model

- Max Thrust

- Recommended takeoff weight per axis

- Efficiency of recommended takeoff weight

- Input voltage*

- Rated voltage

- Lithium compatible

- Tube outer diameter

- Weight(with cable and 72inch Prop)

- Cable specification

- Operating temperature

- Ingress Protection

- Rated power input

- Rated power output

-

- P65M

- 138 kg

- 65kg

- 7.4g/W / 6.3g/W

- 280~450 V

- 335 V

- 96~107S(LiPo)

- Φ60mm

- 7450 g* / 7180 g*

- Power cable:10AWG 400 mm* Signal cable:800 mm*

- -35~55℃

- IP35

- 10.3 kW

- 8.8 kW

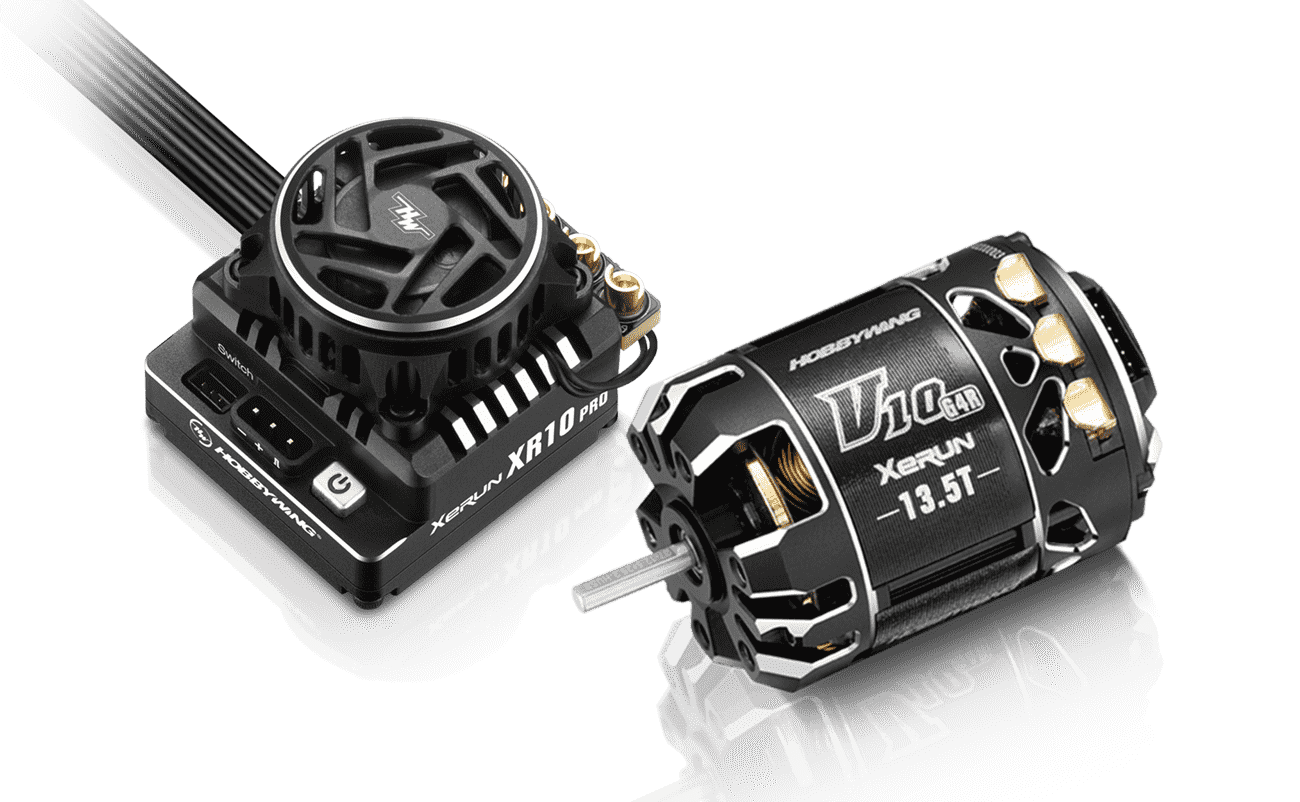

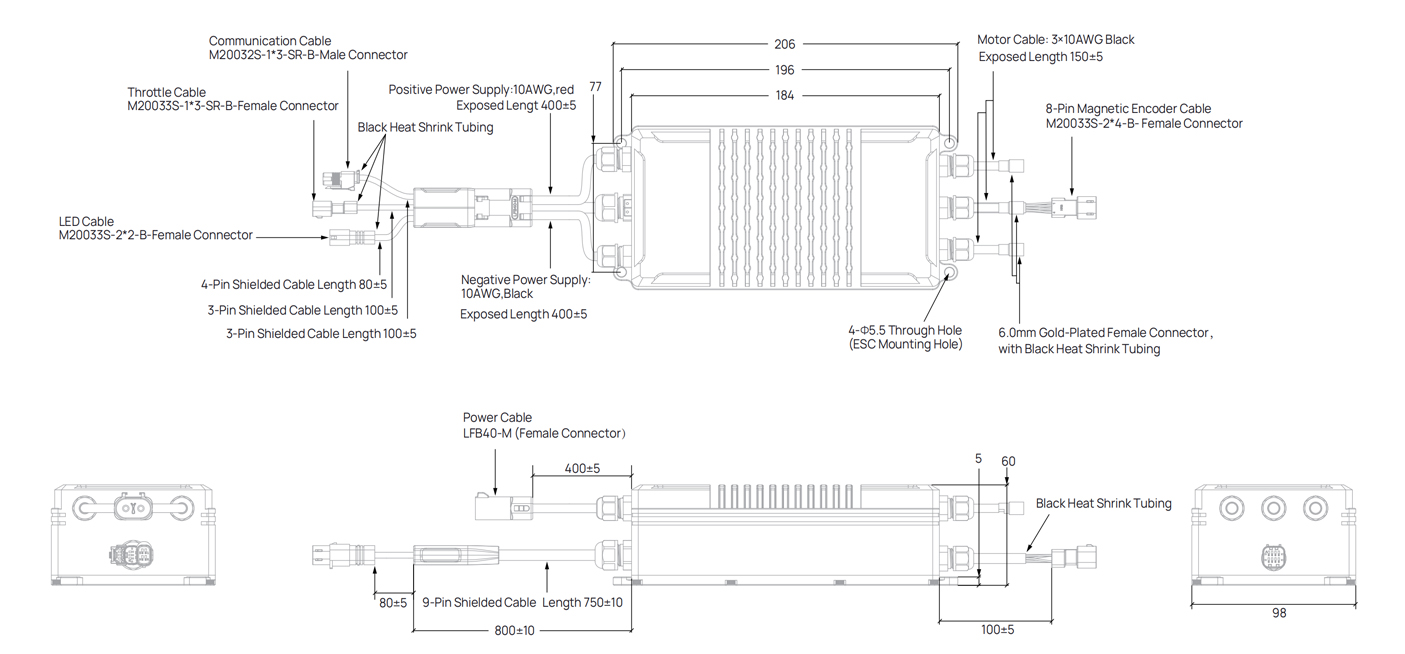

-

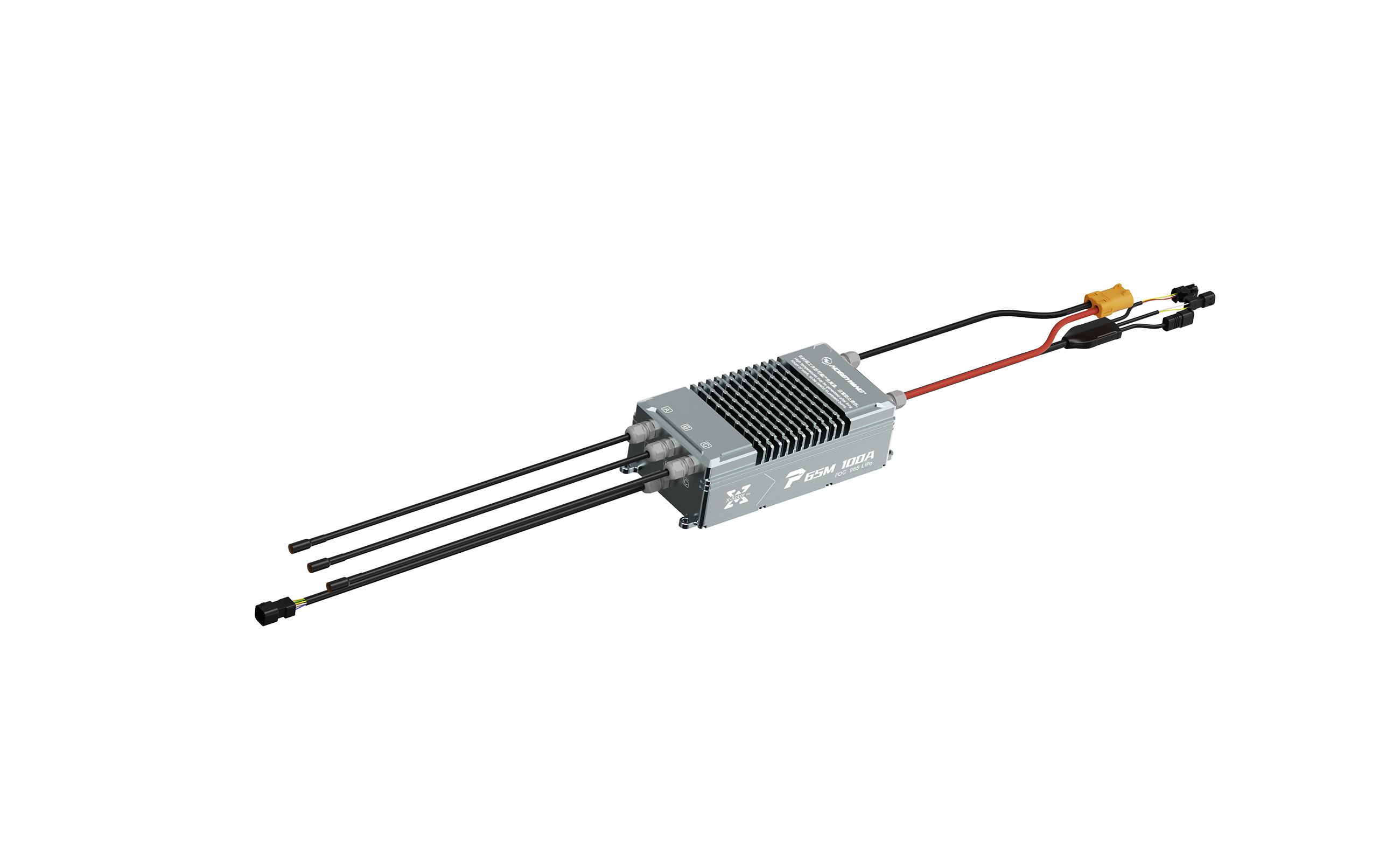

- Rated voltage

- Communication protocol

- ESC size

- Weight(with cable)

- Peak current (3 seconds)

- Continuous current

- Ingress Protection

- Throttle Source

- Operating pulse width(Nonsupport calibration)

- Black box

-

- 335 V

- UAVCAN / RS485

- 225.6*98*60 mm(With plug)

- 1200 g*

- 100A

- 40A

- IP67

- CAN+RS485 / CAN+PWM / RS485+PWM

- 1100~1940 μs

- 2~48h log

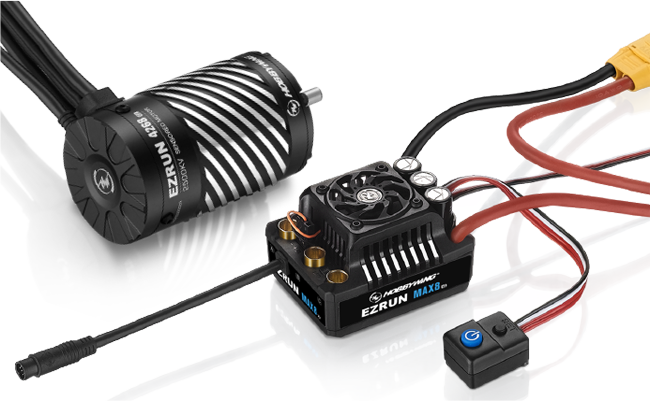

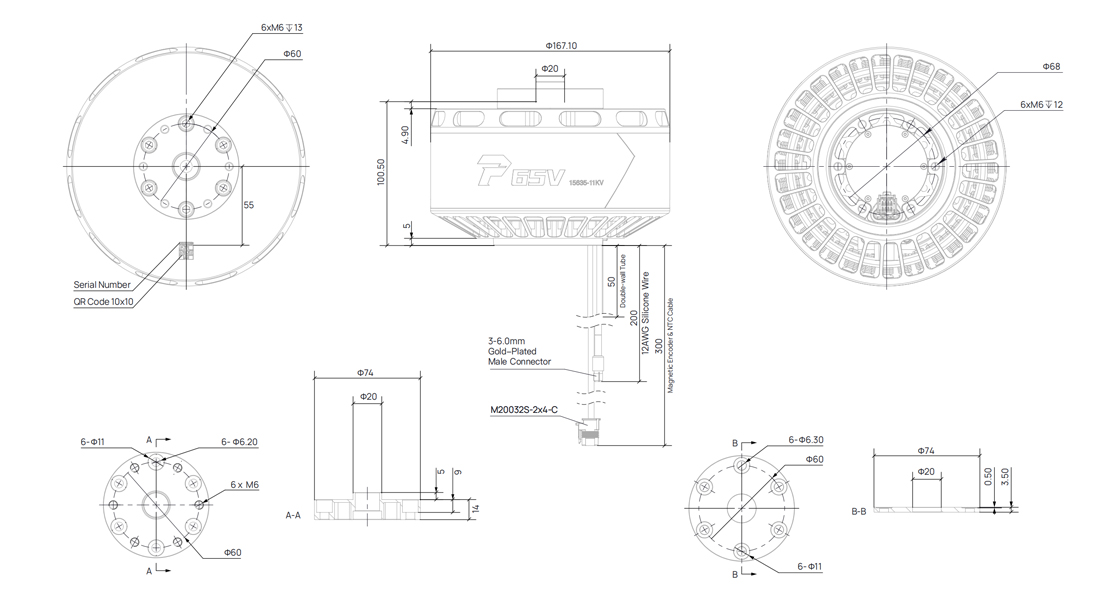

-

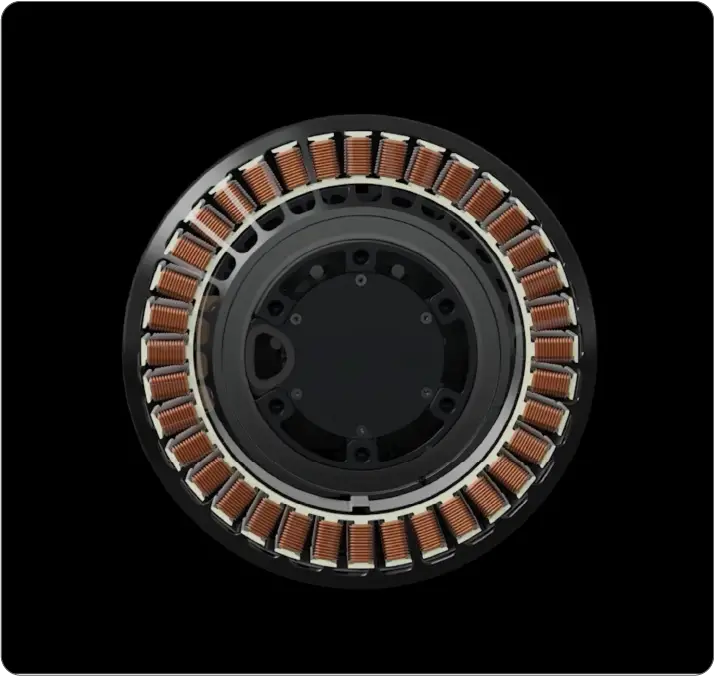

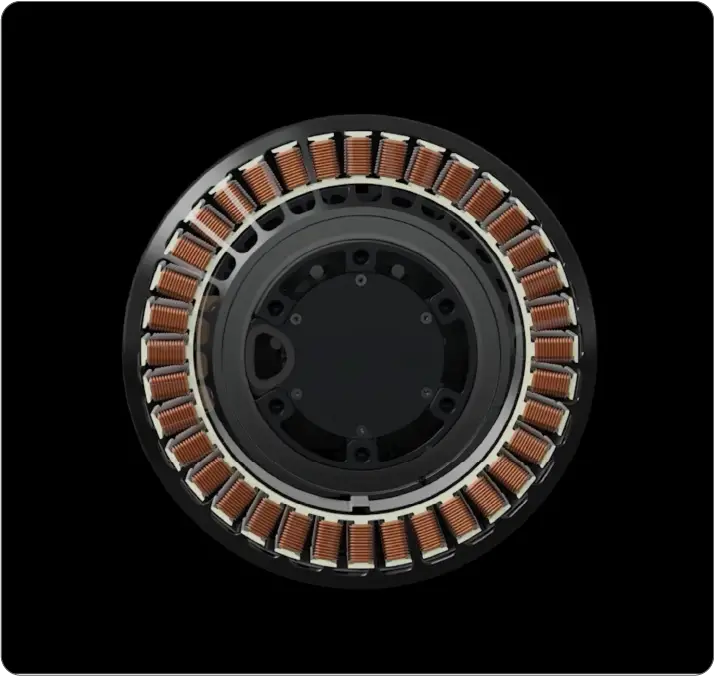

- KV

- Slot& Pole

- Motor size

- Stator size

- Ingress Protection

- Weight(with cable)

-

- 9.5KV / 11KV

- 36N 42P

- Φ167.1*H110.5 mm

- Φ156*H45 mm

- IPX5

- 5115 g*

-

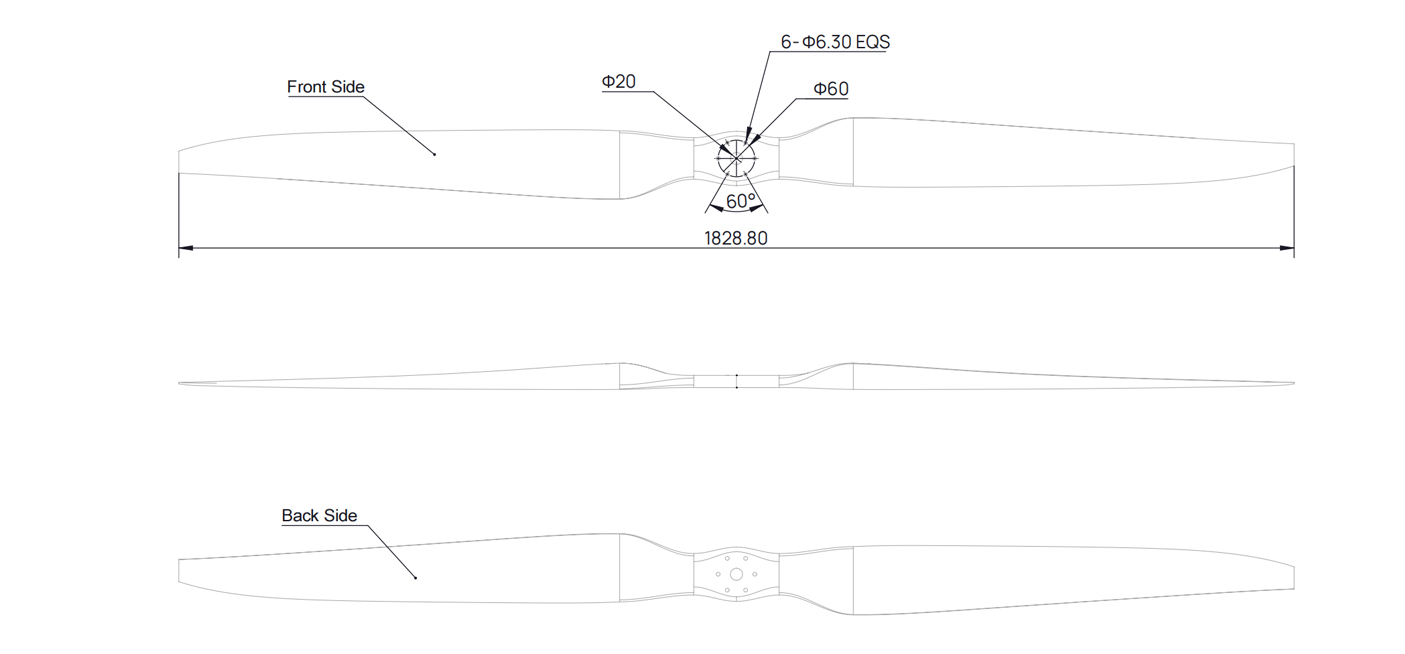

- Model

- Weight

- Material of propeller

- Mounting dimensions

-

- MSC 72x25 / MSC 64x20

- 1150 g* / 870 g*

- Carbon fiber composite material

- D60-6*M6, centre hole D20

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

400V |

MSC 72x25 |

33% |

30231 |

7.5 |

2980.8 |

1124 |

10.1 |

20.51 |

2414.2 |

91.2℃ |

|

35% |

34184 |

8.8 |

3505.3 |

1194 |

9.8 |

23.08 |

2885.5 |

|||

|

37% |

38305 |

10.3 |

4107.8 |

1263 |

9.3 |

25.85 |

3418.4 |

|||

|

39% |

42560 |

11.9 |

4778.0 |

1329 |

8.9 |

28.77 |

4003.4 |

|||

|

42% |

49129 |

14.7 |

5888.8 |

1425 |

8.3 |

33.33 |

4974.0 |

|||

|

45% |

55849 |

17.8 |

7100.7 |

1516 |

7.9 |

38.01 |

6034.5 |

|||

|

48% |

62655 |

21.0 |

8393.5 |

1602 |

7.5 |

42.72 |

7166.1 |

|||

|

51% |

69493 |

24.4 |

9756.8 |

1685 |

7.1 |

47.40 |

8363.9 |

|||

|

54% |

76320 |

28.0 |

11187.9 |

1764 |

6.8 |

52.05 |

9614.8 |

|||

|

57% |

83097 |

31.7 |

12688.4 |

1839 |

6.5 |

56.67 |

10913.0 |

|||

|

60% |

89788 |

35.7 |

14260.2 |

1909 |

6.3 |

61.27 |

12247.4 |

|||

|

63% |

96354 |

39.8 |

15901.2 |

1976 |

6.1 |

65.85 |

13624.7 |

|||

|

66% |

102750 |

44.0 |

17601.4 |

2037 |

5.8 |

70.39 |

15014.4 |

|||

|

69% |

108922 |

48.3 |

19339.6 |

2093 |

5.6 |

74.85 |

16405.1 |

|||

|

72% |

114801 |

52.7 |

21081.6 |

2143 |

5.4 |

79.16 |

17763.1 |

|||

|

75% |

120302 |

56.9 |

22779.0 |

2189 |

5.3 |

83.20 |

19071.0 |

|||

|

78% |

125316 |

60.9 |

24372.0 |

2228 |

5.1 |

86.86 |

20263.4 |

|||

|

81% |

129712 |

64.5 |

25791.9 |

2262 |

5.0 |

89.99 |

21315.2 |

|||

|

84% |

133328 |

67.4 |

26966.4 |

2289 |

4.9 |

92.49 |

22167.8 |

|||

|

87% |

135969 |

69.6 |

27822.4 |

2309 |

4.9 |

94.24 |

22786.0 |

|||

|

100% |

136594 |

70.1 |

28024.2 |

2314 |

4.9 |

94.65 |

22933.6 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

335V |

MSC 64x20 |

33% |

27303 |

9.0 |

3024.5 |

1311 |

9.0 |

17.56 |

2410.0 |

92.6℃ |

|

35% |

31203 |

10.8 |

3609.1 |

1399 |

8.6 |

20.05 |

2937.5 |

|||

|

37% |

35193 |

12.7 |

4262.5 |

1484 |

8.3 |

22.64 |

3518.2 |

|||

|

39% |

39272 |

14.9 |

4978.9 |

1567 |

7.9 |

25.31 |

4152.5 |

|||

|

42% |

45543 |

18.4 |

6159.3 |

1686 |

7.4 |

29.42 |

5194.6 |

|||

|

45% |

51975 |

22.2 |

7452.1 |

1799 |

7.0 |

33.64 |

6337.4 |

|||

|

48% |

58531 |

26.4 |

8844.2 |

1906 |

6.6 |

37.93 |

7570.0 |

|||

|

51% |

65163 |

30.8 |

10326.5 |

2008 |

6.3 |

42.26 |

8885.6 |

|||

|

54% |

71817 |

35.5 |

11893.1 |

2105 |

6.0 |

46.62 |

10274.9 |

|||

|

57% |

78436 |

40.4 |

13538.8 |

2196 |

5.8 |

50.98 |

11722.6 |

|||

|

60% |

84957 |

45.5 |

15256.5 |

2282 |

5.6 |

55.33 |

13222.0 |

|||

|

63% |

91314 |

50.8 |

17034.5 |

2363 |

5.4 |

59.65 |

14758.7 |

|||

|

66% |

97443 |

56.3 |

18853.9 |

2437 |

5.2 |

63.88 |

16300.6 |

|||

|

69% |

103282 |

61.8 |

20687.8 |

2507 |

5.0 |

67.97 |

17843.7 |

|||

|

72% |

108772 |

67.2 |

22502.2 |

2570 |

4.8 |

71.86 |

19339.5 |

|||

|

75% |

113858 |

72.4 |

24258.7 |

2627 |

4.7 |

75.49 |

20764.7 |

|||

|

78% |

118495 |

77.4 |

25918.0 |

2677 |

4.6 |

78.78 |

22082.1 |

|||

|

81% |

122645 |

81.9 |

27443.6 |

2721 |

4.5 |

81.69 |

23274.0 |

|||

|

84% |

126281 |

86.0 |

28806.0 |

2759 |

4.4 |

84.18 |

24321.1 |

|||

|

87% |

129390 |

89.5 |

29984.6 |

2791 |

4.3 |

86.27 |

25211.8 |

|||

|

90% |

131973 |

92.4 |

30969.6 |

2816 |

4.3 |

87.95 |

25932.8 |

|||

|

100% |

135161 |

96.1 |

32188.0 |

2848 |

4.2 |

89.94 |

26821.9 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

400V |

MSC 64x20 |

33% |

27109 |

7.6 |

3031.6 |

1312 |

8.9 |

17.41 |

2392.0 |

92.8℃ |

|

35% |

31142 |

9.0 |

3609.0 |

1399 |

8.6 |

19.98 |

2927.1 |

|||

|

37% |

35131 |

10.7 |

4270.4 |

1483 |

8.2 |

22.59 |

3507.2 |

|||

|

39% |

39130 |

12.5 |

4999.2 |

1565 |

7.8 |

25.23 |

4134.4 |

|||

|

42% |

45227 |

15.5 |

6196.0 |

1685 |

7.3 |

29.28 |

5165.9 |

|||

|

45% |

51505 |

18.7 |

7496.2 |

1799 |

6.9 |

33.43 |

6297.4 |

|||

|

48% |

57983 |

22.2 |

8884.4 |

1907 |

6.5 |

37.67 |

7522.8 |

|||

|

51% |

64635 |

25.9 |

10353.8 |

2009 |

6.2 |

41.99 |

8833.5 |

|||

|

54% |

71399 |

29.8 |

11906.5 |

2105 |

6.0 |

46.37 |

10219.7 |

|||

|

57% |

78182 |

33.9 |

13549.7 |

2196 |

5.8 |

50.78 |

11675.9 |

|||

|

60% |

84876 |

38.2 |

15287.0 |

2281 |

5.6 |

55.20 |

13183.3 |

|||

|

63% |

91365 |

42.8 |

17108.5 |

2363 |

5.3 |

59.57 |

14740.9 |

|||

|

66% |

97534 |

47.5 |

18983.3 |

2439 |

5.1 |

63.84 |

16304.9 |

|||

|

69% |

103278 |

52.1 |

20859.9 |

2511 |

5.0 |

67.91 |

17854.6 |

|||

|

72% |

108515 |

56.7 |

22674.3 |

2576 |

4.8 |

71.67 |

19331.2 |

|||

|

75% |

113190 |

60.9 |

24364.4 |

2632 |

4.6 |

75.04 |

20682.3 |

|||

|

78% |

117291 |

64.7 |

25885.4 |

2681 |

4.5 |

77.99 |

21895.3 |

|||

|

81% |

120853 |

68.1 |

27220.9 |

2721 |

4.4 |

80.52 |

22941.7 |

|||

|

84% |

123973 |

71.0 |

28387.8 |

2754 |

4.4 |

82.68 |

23843.6 |

|||

|

87% |

126813 |

73.6 |

29436.8 |

2781 |

4.3 |

84.59 |

24633.7 |

|||

|

90% |

129615 |

76.1 |

30448.0 |

2805 |

4.3 |

86.41 |

25378.7 |

|||

|

100% |

135144 |

80.8 |

32321.4 |

2843 |

4.2 |

89.69 |

26699.6 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.

Propulsion System

Car Standards

- Software

- Adopts a rigorous modular design.

- Fully Isolated Architecture with Protective Earthing

- High-voltage power circuits, low-voltage signal circuits,

- and protective earthing (PE) are completelyisolated,

- delivering reliable data transmission,

- stable system performance,

- and superior safety for operators and equipment alike.

Position Sensor

Real-time RPM acquisition via dual channels,

engineered to meet current airworthiness certification standards

while preparing for future regulatory evolution.

With High Reliability

With High Reliability

.webp)

- High-Temperature ESC with Automotive Components

- The Electric Speed Controller (ESC) uses premium automotive-grade

- components designed for elevated temperature resistance.

- High-Reliability Motor Design

- Built with high-temperature resistant materials and

- equipped with a knurled shaft + dual-screw anti-loosening system for secure.

- long-term performance.

- Propeller

- The propeller adopts carbon fiber molding process.

- Vibration-Resistant Automotive Connectors

- Constructed from automotive-grade materials,

- both high- and low-voltage connectors incorporate fool-proof alignment,

- poor-contact prevention, and superior vibration resistance

- for rock-solid system connectivityand extended service life.

Swipe left to view all

Swipe left to view alland Triple Throttle Control Modes

Triple throttle control modes are as follows:

1

- PWM+CAN digital throttle

- is the default configuration

2

- PWM+RS485

- is optional

3

- CAN+RS485

- is optional

data exchange and ongoing monitoring ofessential parameters:

(RPM,throttle position, current, voltage, and temperature.)

The resultis rapid analytics, swift corrective action.

and substantiallyelevated fight safety.

for Superior Safety

Direct RPM acquisition using a physical sensor for precise,

dependable motor control.

RPM signal intelligently calculated through software algorithms,

eliminating the need for a physical sensor.

Extensively validated with over

1000 hours of aging testing,

guaranteeing maintenance-free

reliability for the entire service life.

developed and designed by HOBBYWING,

ensuring meticulous attention to every detail

millisecond-level recording of real-time operational data,

enabling comprehensive traceability analysis

The fault storage function records operational fault codes during operation,

enabling precise root cause tracing.

The system continuously records the drone's operational data for 2-48 hours,

facilitating comprehensive post-flight data analysis.

Firmware OTA Updates

With HOBBYWING’s proprietary host computer software (DataLink),

users can adjust drive parameters, motor direction,

and LED color (default green) effortlessly to optimize flight performance

and upgrade the latest firmware.

Compatibility

Compatible with mainstream flight controller systems such as

ArduPilot open-source ecosystem, VK, Byaero and Jiyi, supports CAN communication,

and builds an intelligent flight ecosystem.

Feedback of Coil Temperature

Monitor the temperature rise data during motor operation in real time

and take timely countermeasures to ensure flight safety.

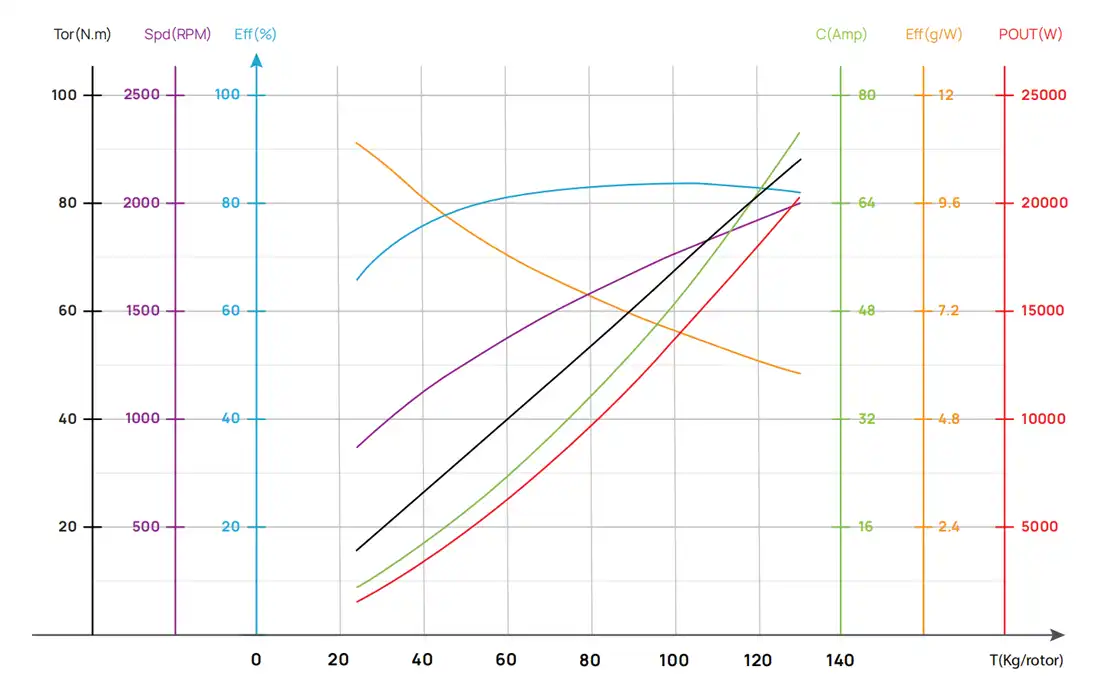

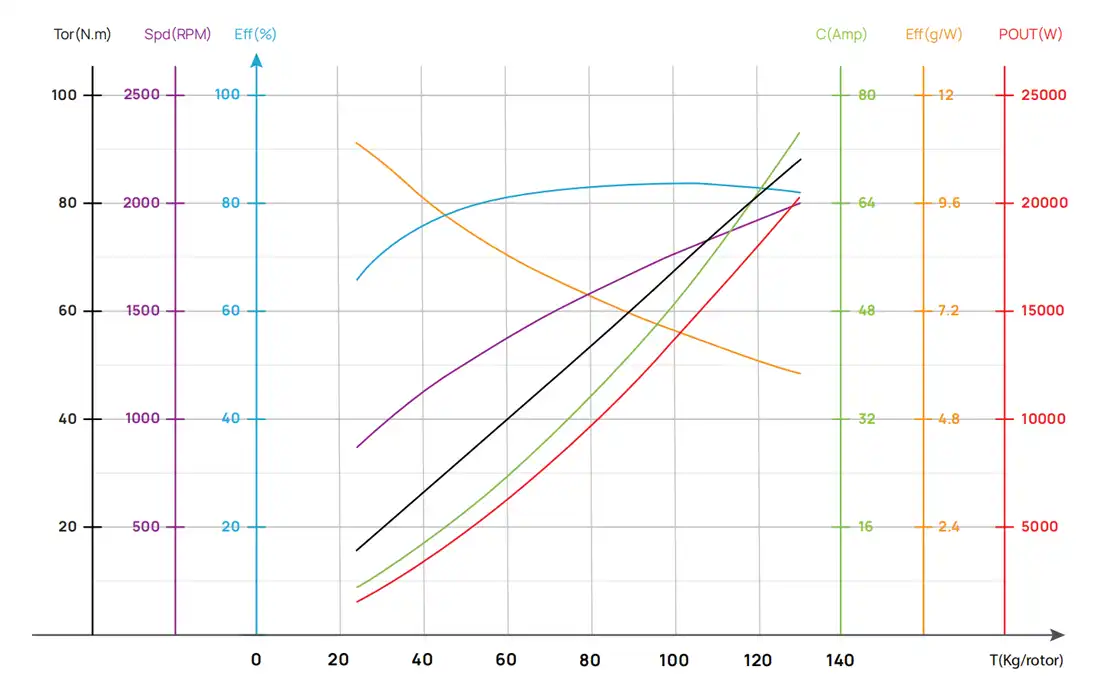

- *The above data were measured at room temperature (25℃) and sea level, and the motor and ESC were under the condition of good heat dissipation.

- The abscissa represents the maximum safe operating time at each overload point. In actual flight, if the propulsion system exceeds this time,

- there is a high probability of irreversible failure. But for flight safety, the propulsion system will not automatically shut down.

- *The above data were measured at room temperature (25℃) and sea level, and the motor and ESC were under the condition of good heat dissipation.

- The abscissa represents the maximum safe operating time at each overload point. In actual flight, if the propulsion system exceeds this time,

- there is a high probability of irreversible failure. But for flight safety, the propulsion system will not automatically shut down.

-

- Thank you for your interest in HOBBYWING propulsion systems! For customized solutions, please provide your contact information and technical requirements, and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

-

- Model

- Max Thrust

- Recommended takeoff weight per axis

- Efficiency of recommended takeoff weight

- Input voltage*

- Rated voltage

- Lithium compatible

- Tube outer diameter

- Weight(with cable and 72inch Prop)

- Cable specification

- Operating temperature

- Ingress Protection

- Rated power input

- Rated power output

-

- P65M

- 138 kg

- 65kg

- 7.4g/W / 6.3g/W

- 280~450 V

- 335 V

- 96~107S(LiPo)

- Φ60mm

- 7450 g* / 7180 g*

- Power cable:10AWG 400 mm* Signal cable:800 mm*

- -35~55℃

- IP35

- 10.3 kW

- 8.8 kW

-

- Rated voltage

- Communication protocol

- ESC size

- Weight(with cable)

- Peak current (3 seconds)

- Continuous current

- Ingress Protection

- Throttle Source

- Operating pulse width(Nonsupport calibration)

- Black box

-

- 335 V

- UAVCAN / RS485

- 225.6*98*60 mm(With plug)

- 1200 g*

- 100A

- 40A

- IP67

- CAN+RS485 / CAN+PWM / RS485+PWM

- 1100~1940 μs

- 2~48h log

-

- KV

- Slot& Pole

- Motor size

- Stator size

- Ingress Protection

- Weight(with cable)

-

- 9.5KV / 11KV

- 36N 42P

- Φ167.1*H110.5 mm

- Φ156*H45 mm

- IPX5

- 5115 g*

-

- Model

- Weight

- Material of propeller

- Mounting dimensions

-

- MSC 72x25 / MSC 64x20

- 1150 g* / 870 g*

- Carbon fiber composite material

- D60-6*M6, centre hole D20

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

335V |

MSC 72x25 |

33% |

30509 |

8.9 |

2977.0 |

1124 |

10.2 |

20.70 |

2436.1 |

90.6℃ |

|

35% |

34417 |

10.5 |

3507.5 |

1194 |

9.8 |

23.33 |

2917.0 |

|||

|

37% |

38496 |

12.3 |

4104.4 |

1262 |

9.4 |

26.09 |

3448.1 |

|||

|

39% |

42717 |

14.2 |

4761.5 |

1328 |

9.0 |

28.96 |

4027.0 |

|||

|

42% |

49254 |

17.5 |

5846.3 |

1424 |

8.4 |

33.41 |

4981.4 |

|||

|

45% |

55964 |

21.0 |

7034.1 |

1515 |

8.0 |

37.98 |

6025.0 |

|||

|

49% |

65058 |

26.1 |

8755.8 |

1630 |

7.4 |

44.19 |

7542.6 |

|||

|

51% |

69627 |

28.9 |

9670.6 |

1685 |

7.2 |

47.33 |

8350.0 |

|||

|

54% |

76464 |

33.2 |

11106.8 |

1765 |

6.9 |

52.04 |

9618.1 |

|||

|

57% |

83239 |

37.7 |

12617.1 |

1840 |

6.6 |

56.76 |

10935.1 |

|||

|

60% |

89906 |

42.4 |

14196.4 |

1911 |

6.3 |

61.44 |

12295.3 |

|||

|

63% |

96424 |

47.3 |

15835.4 |

1977 |

6.1 |

66.08 |

13678.7 |

|||

|

66% |

102751 |

52.3 |

17518.4 |

2038 |

5.9 |

70.61 |

15068.4 |

|||

|

69% |

108843 |

57.4 |

19222.2 |

2094 |

5.7 |

75.00 |

16444.2 |

|||

|

72% |

114651 |

62.4 |

20916.0 |

2145 |

5.5 |

79.17 |

17782.8 |

|||

|

75% |

120124 |

67.4 |

22562.7 |

2191 |

5.3 |

83.07 |

19059.1 |

|||

|

78% |

125200 |

72.0 |

24120.4 |

2232 |

5.2 |

86.63 |

20246.6 |

|||

|

81% |

129809 |

76.3 |

25546.1 |

2267 |

5.1 |

89.77 |

21310.4 |

|||

|

84% |

133869 |

80.0 |

26798.1 |

2297 |

5.0 |

92.45 |

22235.8 |

|||

|

87% |

137287 |

83.1 |

27838.9 |

2323 |

4.9 |

94.61 |

23013.2 |

|||

|

100% |

138264 |

84.0 |

28133.1 |

2330 |

4.9 |

95.21 |

23229.1 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

400V |

MSC 72x25 |

33% |

30231 |

7.5 |

2980.8 |

1124 |

10.1 |

20.51 |

2414.2 |

91.2℃ |

|

35% |

34184 |

8.8 |

3505.3 |

1194 |

9.8 |

23.08 |

2885.5 |

|||

|

37% |

38305 |

10.3 |

4107.8 |

1263 |

9.3 |

25.85 |

3418.4 |

|||

|

39% |

42560 |

11.9 |

4778.0 |

1329 |

8.9 |

28.77 |

4003.4 |

|||

|

42% |

49129 |

14.7 |

5888.8 |

1425 |

8.3 |

33.33 |

4974.0 |

|||

|

45% |

55849 |

17.8 |

7100.7 |

1516 |

7.9 |

38.01 |

6034.5 |

|||

|

48% |

62655 |

21.0 |

8393.5 |

1602 |

7.5 |

42.72 |

7166.1 |

|||

|

51% |

69493 |

24.4 |

9756.8 |

1685 |

7.1 |

47.40 |

8363.9 |

|||

|

54% |

76320 |

28.0 |

11187.9 |

1764 |

6.8 |

52.05 |

9614.8 |

|||

|

57% |

83097 |

31.7 |

12688.4 |

1839 |

6.5 |

56.67 |

10913.0 |

|||

|

60% |

89788 |

35.7 |

14260.2 |

1909 |

6.3 |

61.27 |

12247.4 |

|||

|

63% |

96354 |

39.8 |

15901.2 |

1976 |

6.1 |

65.85 |

13624.7 |

|||

|

66% |

102750 |

44.0 |

17601.4 |

2037 |

5.8 |

70.39 |

15014.4 |

|||

|

69% |

108922 |

48.3 |

19339.6 |

2093 |

5.6 |

74.85 |

16405.1 |

|||

|

72% |

114801 |

52.7 |

21081.6 |

2143 |

5.4 |

79.16 |

17763.1 |

|||

|

75% |

120302 |

56.9 |

22779.0 |

2189 |

5.3 |

83.20 |

19071.0 |

|||

|

78% |

125316 |

60.9 |

24372.0 |

2228 |

5.1 |

86.86 |

20263.4 |

|||

|

81% |

129712 |

64.5 |

25791.9 |

2262 |

5.0 |

89.99 |

21315.2 |

|||

|

84% |

133328 |

67.4 |

26966.4 |

2289 |

4.9 |

92.49 |

22167.8 |

|||

|

87% |

135969 |

69.6 |

27822.4 |

2309 |

4.9 |

94.24 |

22786.0 |

|||

|

100% |

136594 |

70.1 |

28024.2 |

2314 |

4.9 |

94.65 |

22933.6 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

335V |

MSC 64x20 |

33% |

27303 |

9.0 |

3024.5 |

1311 |

9.0 |

17.56 |

2410.0 |

92.6℃ |

|

35% |

31203 |

10.8 |

3609.1 |

1399 |

8.6 |

20.05 |

2937.5 |

|||

|

37% |

35193 |

12.7 |

4262.5 |

1484 |

8.3 |

22.64 |

3518.2 |

|||

|

39% |

39272 |

14.9 |

4978.9 |

1567 |

7.9 |

25.31 |

4152.5 |

|||

|

42% |

45543 |

18.4 |

6159.3 |

1686 |

7.4 |

29.42 |

5194.6 |

|||

|

45% |

51975 |

22.2 |

7452.1 |

1799 |

7.0 |

33.64 |

6337.4 |

|||

|

48% |

58531 |

26.4 |

8844.2 |

1906 |

6.6 |

37.93 |

7570.0 |

|||

|

51% |

65163 |

30.8 |

10326.5 |

2008 |

6.3 |

42.26 |

8885.6 |

|||

|

54% |

71817 |

35.5 |

11893.1 |

2105 |

6.0 |

46.62 |

10274.9 |

|||

|

57% |

78436 |

40.4 |

13538.8 |

2196 |

5.8 |

50.98 |

11722.6 |

|||

|

60% |

84957 |

45.5 |

15256.5 |

2282 |

5.6 |

55.33 |

13222.0 |

|||

|

63% |

91314 |

50.8 |

17034.5 |

2363 |

5.4 |

59.65 |

14758.7 |

|||

|

66% |

97443 |

56.3 |

18853.9 |

2437 |

5.2 |

63.88 |

16300.6 |

|||

|

69% |

103282 |

61.8 |

20687.8 |

2507 |

5.0 |

67.97 |

17843.7 |

|||

|

72% |

108772 |

67.2 |

22502.2 |

2570 |

4.8 |

71.86 |

19339.5 |

|||

|

75% |

113858 |

72.4 |

24258.7 |

2627 |

4.7 |

75.49 |

20764.7 |

|||

|

78% |

118495 |

77.4 |

25918.0 |

2677 |

4.6 |

78.78 |

22082.1 |

|||

|

81% |

122645 |

81.9 |

27443.6 |

2721 |

4.5 |

81.69 |

23274.0 |

|||

|

84% |

126281 |

86.0 |

28806.0 |

2759 |

4.4 |

84.18 |

24321.1 |

|||

|

87% |

129390 |

89.5 |

29984.6 |

2791 |

4.3 |

86.27 |

25211.8 |

|||

|

90% |

131973 |

92.4 |

30969.6 |

2816 |

4.3 |

87.95 |

25932.8 |

|||

|

100% |

135161 |

96.1 |

32188.0 |

2848 |

4.2 |

89.94 |

26821.9 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N·m) |

Power Output(W) |

Motor Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|---|

|

400V |

MSC 64x20 |

33% |

27109 |

7.6 |

3031.6 |

1312 |

8.9 |

17.41 |

2392.0 |

92.8℃ |

|

35% |

31142 |

9.0 |

3609.0 |

1399 |

8.6 |

19.98 |

2927.1 |

|||

|

37% |

35131 |

10.7 |

4270.4 |

1483 |

8.2 |

22.59 |

3507.2 |

|||

|

39% |

39130 |

12.5 |

4999.2 |

1565 |

7.8 |

25.23 |

4134.4 |

|||

|

42% |

45227 |

15.5 |

6196.0 |

1685 |

7.3 |

29.28 |

5165.9 |

|||

|

45% |

51505 |

18.7 |

7496.2 |

1799 |

6.9 |

33.43 |

6297.4 |

|||

|

48% |

57983 |

22.2 |

8884.4 |

1907 |

6.5 |

37.67 |

7522.8 |

|||

|

51% |

64635 |

25.9 |

10353.8 |

2009 |

6.2 |

41.99 |

8833.5 |

|||

|

54% |

71399 |

29.8 |

11906.5 |

2105 |

6.0 |

46.37 |

10219.7 |

|||

|

57% |

78182 |

33.9 |

13549.7 |

2196 |

5.8 |

50.78 |

11675.9 |

|||

|

60% |

84876 |

38.2 |

15287.0 |

2281 |

5.6 |

55.20 |

13183.3 |

|||

|

63% |

91365 |

42.8 |

17108.5 |

2363 |

5.3 |

59.57 |

14740.9 |

|||

|

66% |

97534 |

47.5 |

18983.3 |

2439 |

5.1 |

63.84 |

16304.9 |

|||

|

69% |

103278 |

52.1 |

20859.9 |

2511 |

5.0 |

67.91 |

17854.6 |

|||

|

72% |

108515 |

56.7 |

22674.3 |

2576 |

4.8 |

71.67 |

19331.2 |

|||

|

75% |

113190 |

60.9 |

24364.4 |

2632 |

4.6 |

75.04 |

20682.3 |

|||

|

78% |

117291 |

64.7 |

25885.4 |

2681 |

4.5 |

77.99 |

21895.3 |

|||

|

81% |

120853 |

68.1 |

27220.9 |

2721 |

4.4 |

80.52 |

22941.7 |

|||

|

84% |

123973 |

71.0 |

28387.8 |

2754 |

4.4 |

82.68 |

23843.6 |

|||

|

87% |

126813 |

73.6 |

29436.8 |

2781 |

4.3 |

84.59 |

24633.7 |

|||

|

90% |

129615 |

76.1 |

30448.0 |

2805 |

4.3 |

86.41 |

25378.7 |

|||

|

100% |

135144 |

80.8 |

32321.4 |

2843 |

4.2 |

89.69 |

26699.6 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.