|

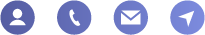

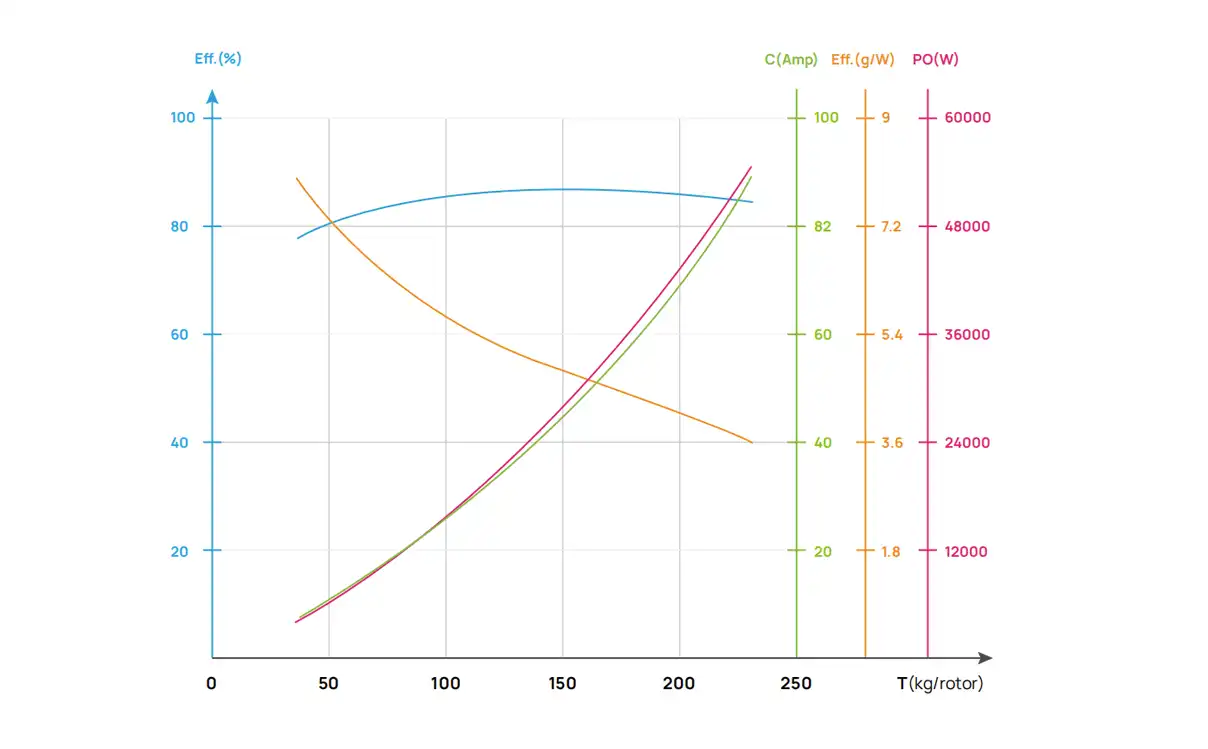

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Efficiency(%) |

Efficiency(g/W) |

Power Output(W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|

|

720V |

MSC 64x23-P |

38% |

63370 |

12.5 |

9007.2 |

82.10 |

7.0 |

7394.9 |

/ |

|

40% |

70510 |

14.5 |

10440.0 |

83.09 |

6.8 |

8674.6 |

|||

|

42% |

77805 |

16.6 |

11980.8 |

83.92 |

6.5 |

10054.3 |

|||

|

44% |

85235 |

18.9 |

13629.6 |

84.60 |

6.3 |

11530.6 |

|||

|

46% |

92777 |

21.4 |

15372.0 |

85.17 |

6.0 |

13092.3 |

|||

|

48% |

100409 |

23.9 |

17215.2 |

85.62 |

5.8 |

14739.7 |

|||

|

50% |

108106 |

26.6 |

19144.8 |

86.00 |

5.6 |

16464.5 |

|||

|

52% |

115840 |

29.4 |

21153.6 |

86.30 |

5.5 |

18255.6 |

|||

|

54% |

123586 |

32.3 |

23234.4 |

86.54 |

5.3 |

20107.0 |

|||

|

56% |

131313 |

35.3 |

25380.0 |

86.74 |

5.2 |

22014.6 |

|||

|

58% |

138994 |

38.3 |

27576.0 |

86.89 |

5.0 |

23960.8 |

|||

|

60% |

146597 |

41.4 |

29815.2 |

87.01 |

4.9 |

25942.2 |

|||

|

62% |

154091 |

44.6 |

32097.6 |

87.08 |

4.8 |

27950.6 |

|||

|

64% |

161446 |

47.8 |

34416.0 |

87.13 |

4.7 |

29986.7 |

|||

|

66% |

168629 |

51.0 |

36748.8 |

87.14 |

4.6 |

32022.9 |

|||

|

68% |

175608 |

54.3 |

39110.4 |

87.11 |

4.5 |

34069.1 |

|||

|

70% |

182351 |

57.6 |

41479.2 |

87.05 |

4.4 |

36107.6 |

|||

|

72% |

188827 |

60.9 |

43848.0 |

86.95 |

4.3 |

38125.8 |

|||

|

76% |

200845 |

67.4 |

48556.8 |

86.65 |

4.1 |

42074.5 |

|||

|

80% |

211414 |

73.8 |

53100.0 |

86.25 |

4.0 |

45798.8 |

|||

|

85% |

222218 |

80.9 |

58248.0 |

85.69 |

3.8 |

49912.7 |

|||

|

100% |

234190 |

89.6 |

64533.6 |

84.97 |

3.6 |

54834.2 |

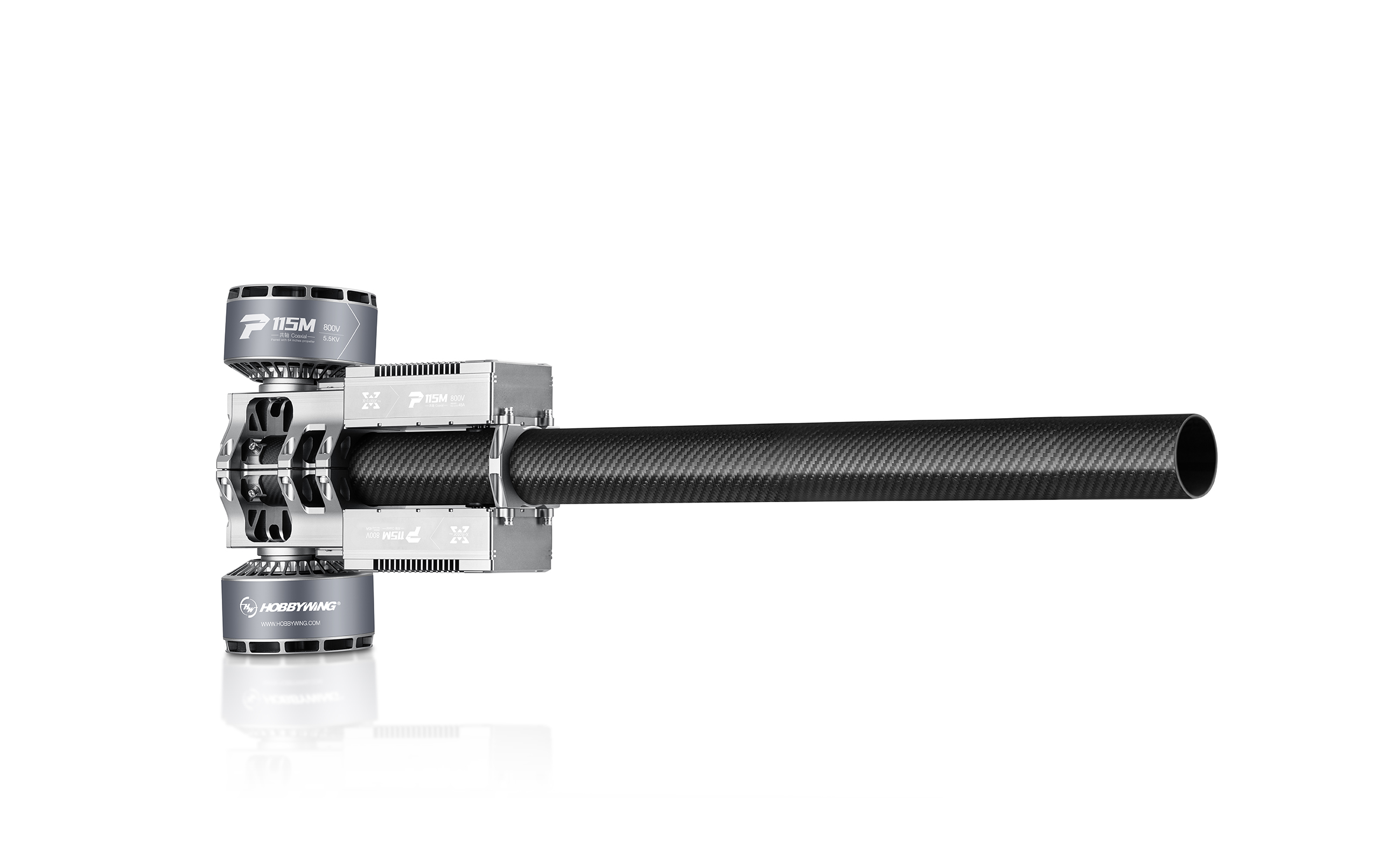

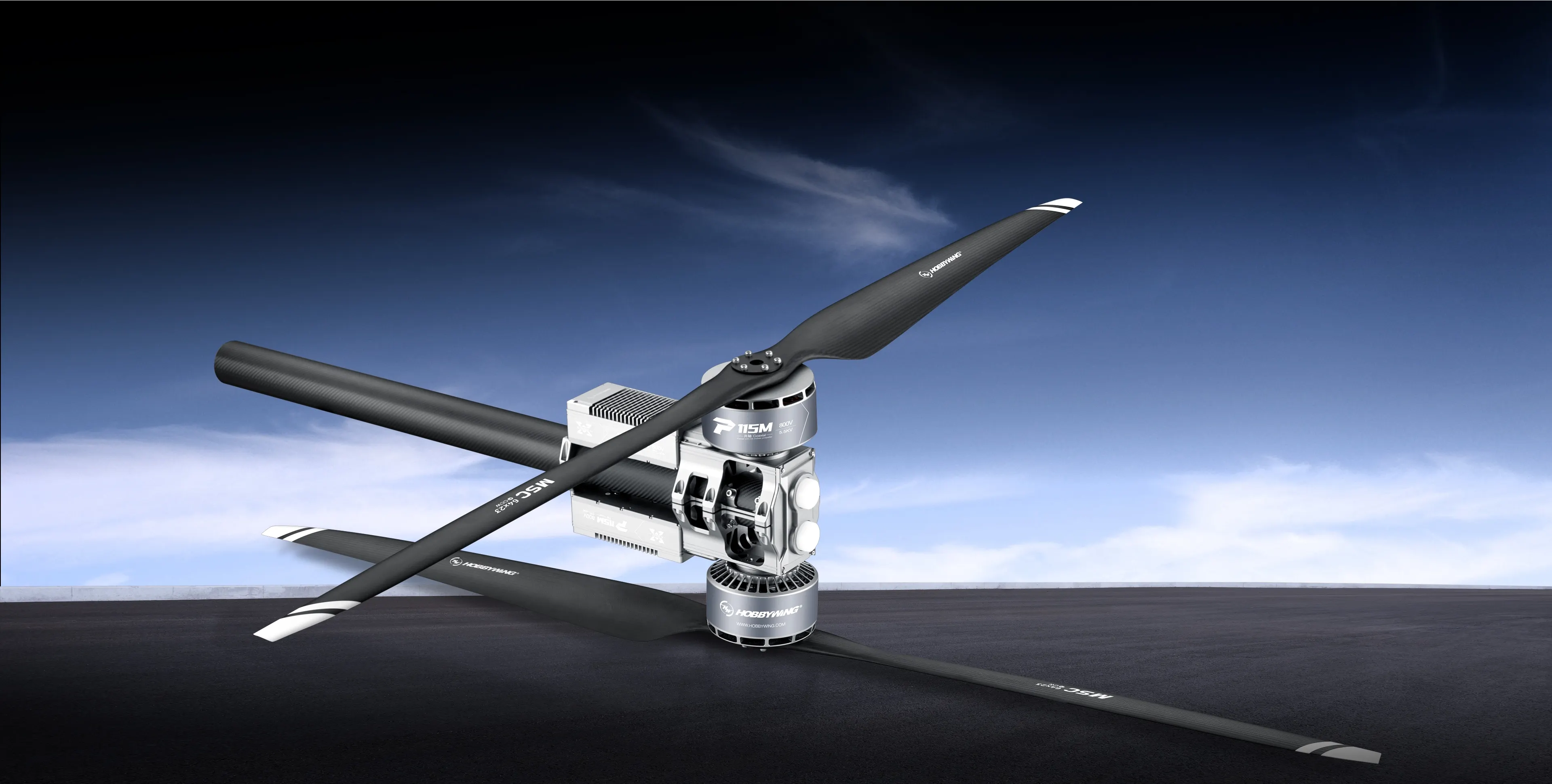

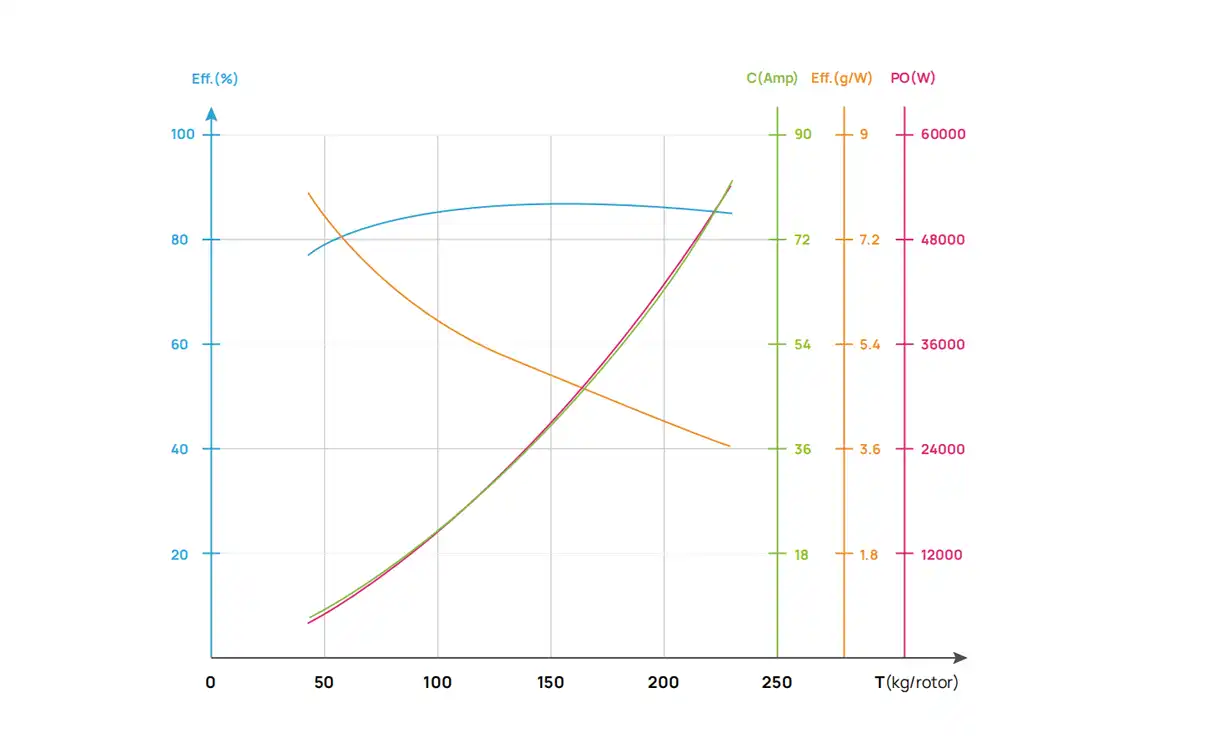

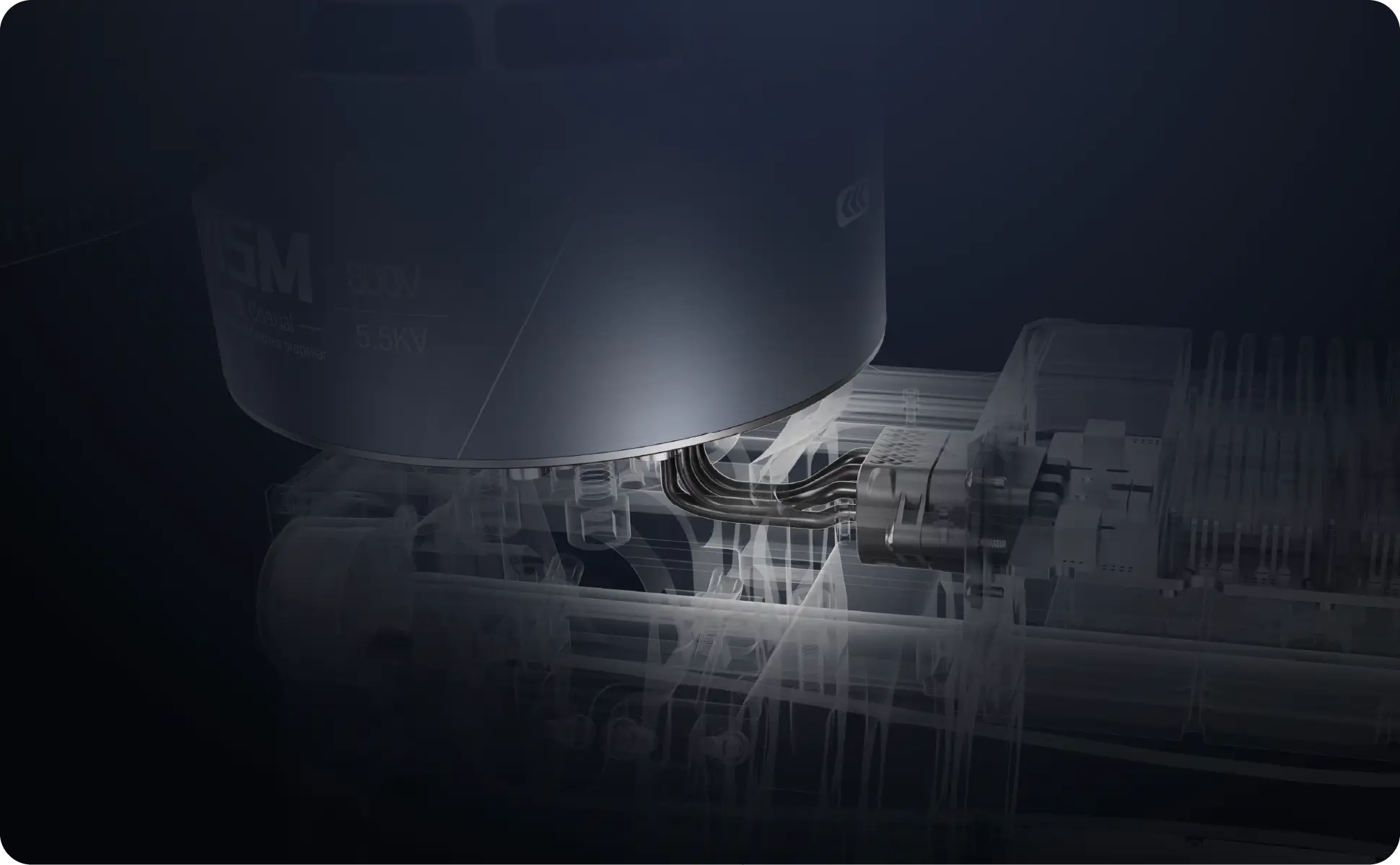

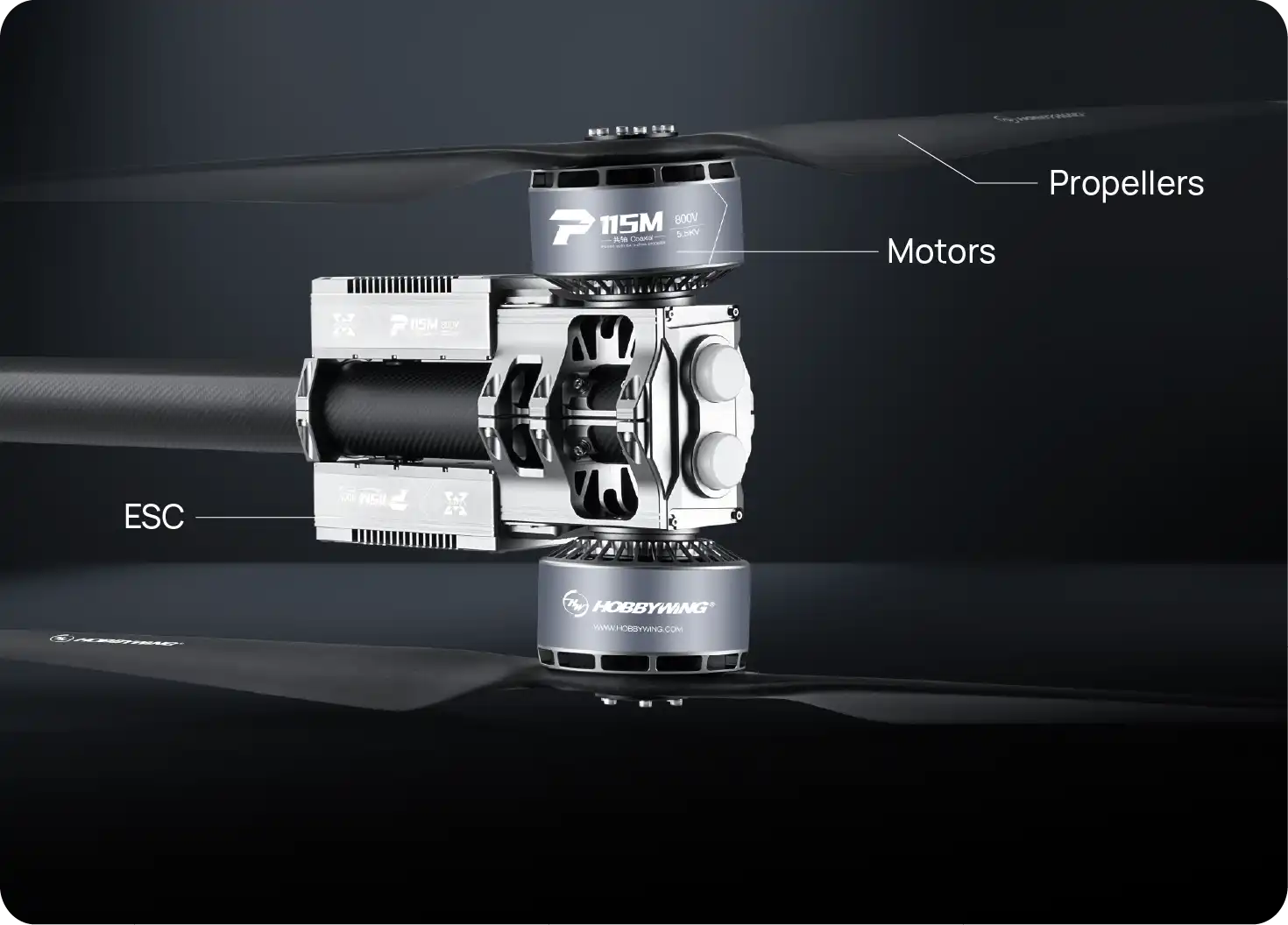

Innovative Design

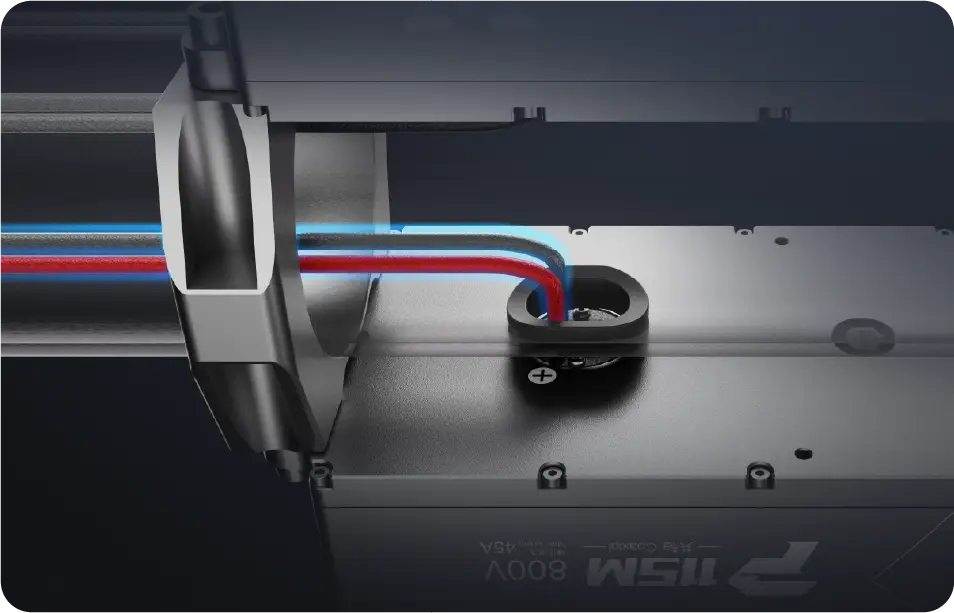

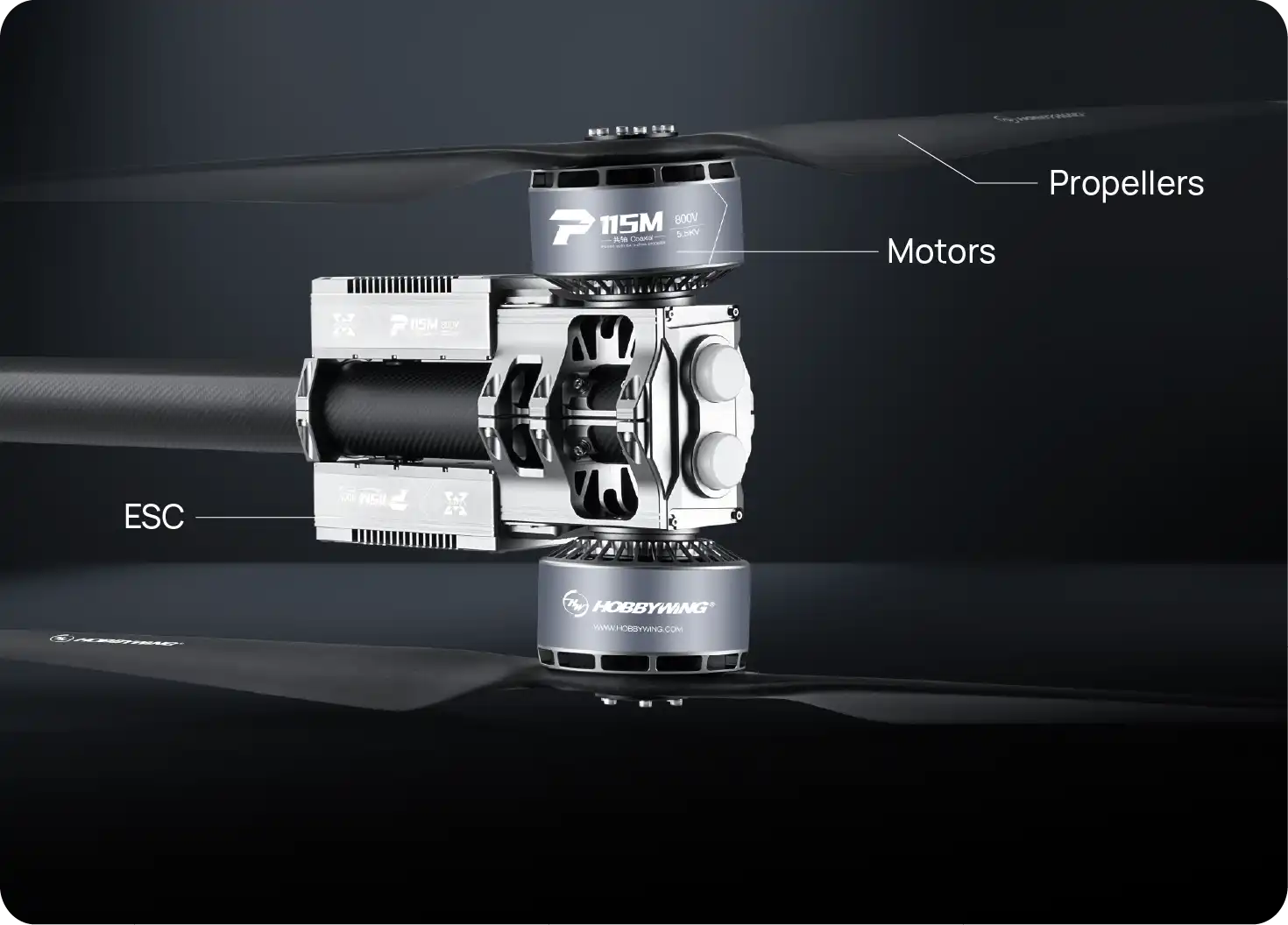

- At 800V and over 100kg-class thrust, the motor, ESC, and propeller are fully integrated in a groundbreaking design that

eliminates exposed cables. This streamlines the entire wiring layout, drastically reduces installation complexity and

maintenance costs, and eliminates failures from cable tension, abrasion, or short circuits at the source.

Significantly Enhancing Overall System Reliability.

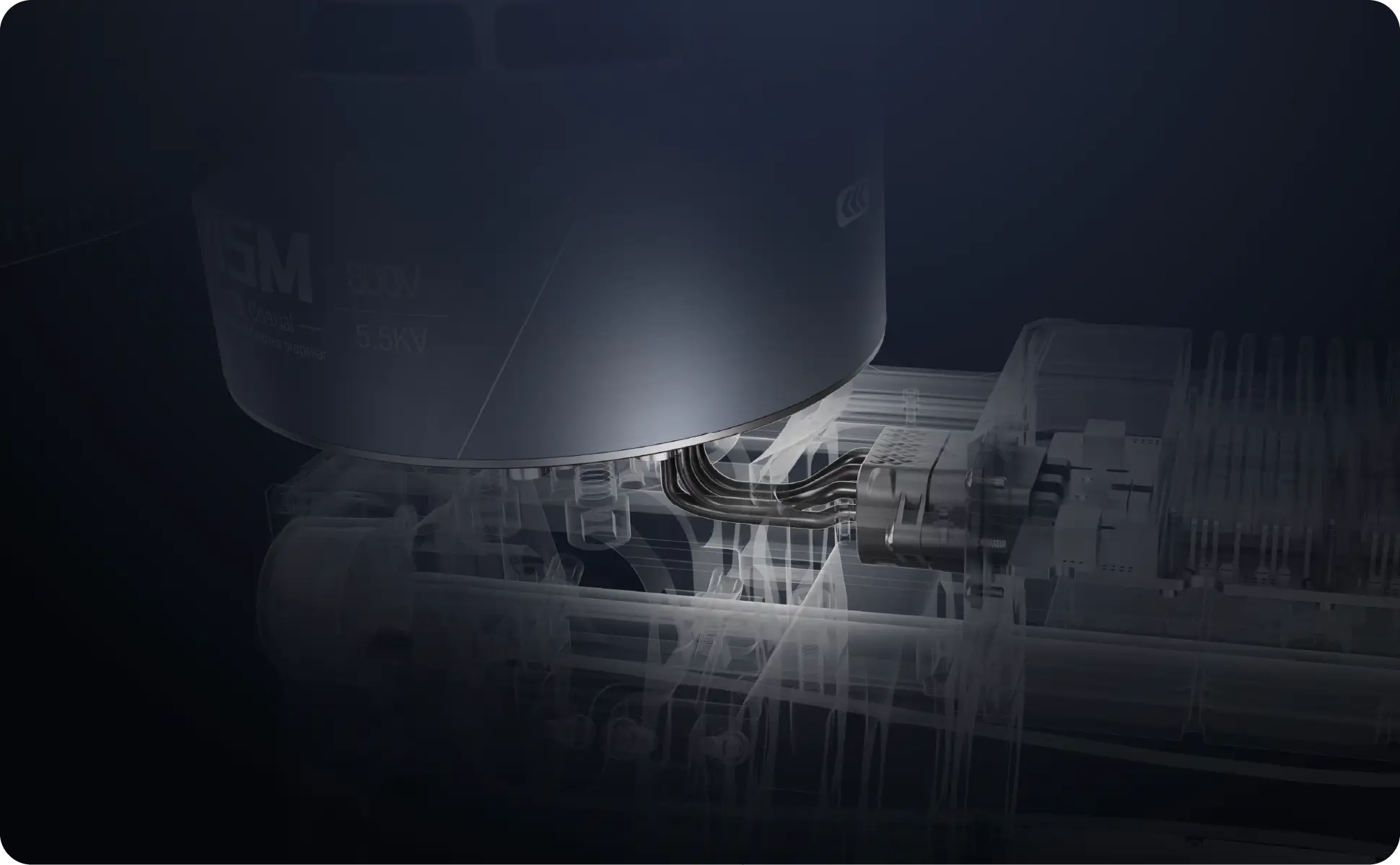

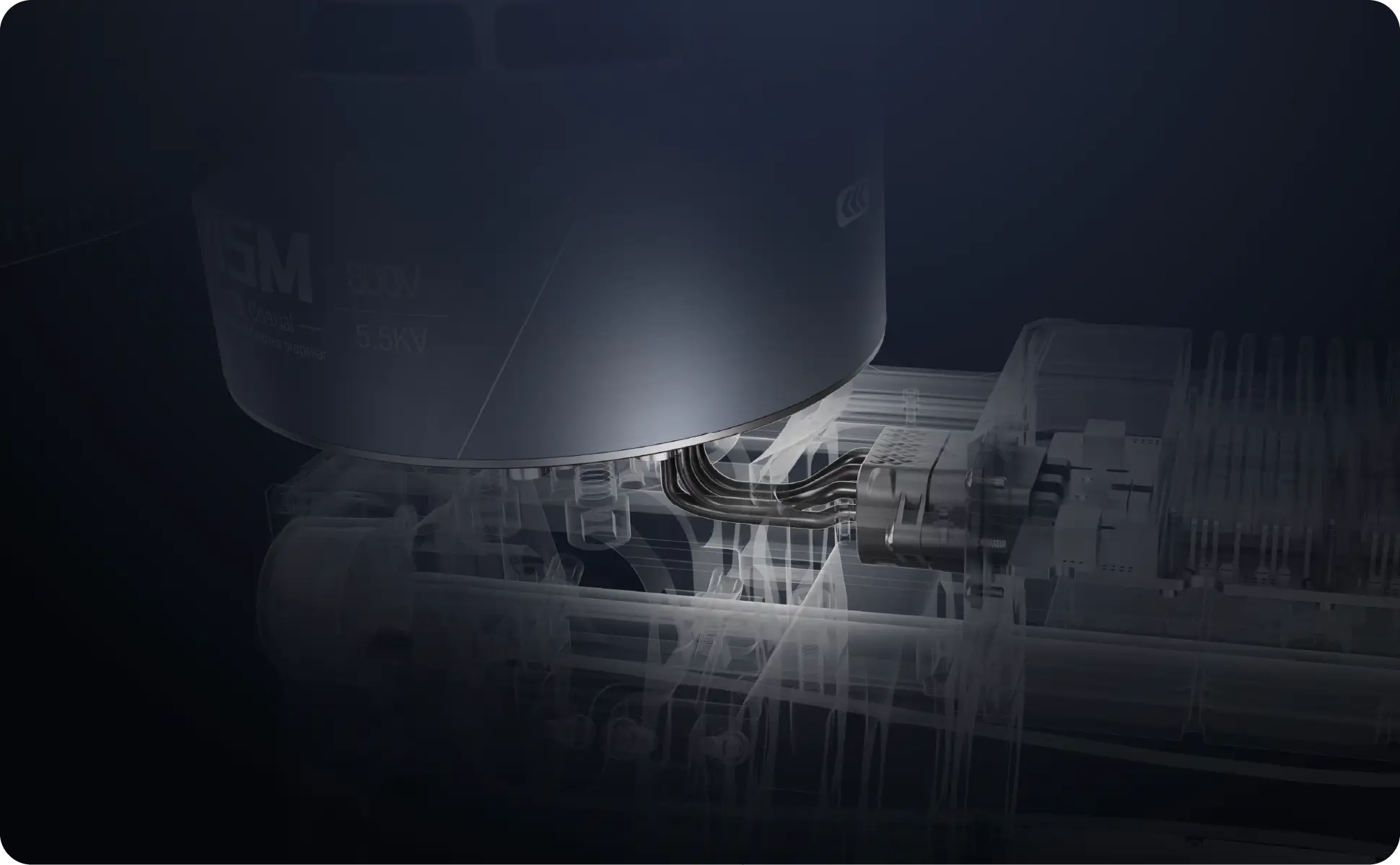

- Shortened Three-Phase Cables minimizes transmission losses and EMI from long runs.

Delivering Higher System Efficiency, Superior Stability, and Cleaner power Performance.

- All wiring placed inside durable carbon tubes to resist aging, moisture ingress, salt spray corrosion, and dust.

Ensuring extended, maintenance-free lifespan in demanding applications.

- The patented internal support structure effectively suppresses vibration and displacement of

arms under heavy-lift conditions, ensuring continuous, stable, and reliable propulsion output.

Compatible with arm thicknesses ranging from 2 mm to 5 mm, accommodating a wide variety

of materials and manufacturing processes for maximum integration flexibility.

- Highly integrated design

- Ultra-short wiring

- All built-in connections

- Innovative patented internal support design for tube clip holder

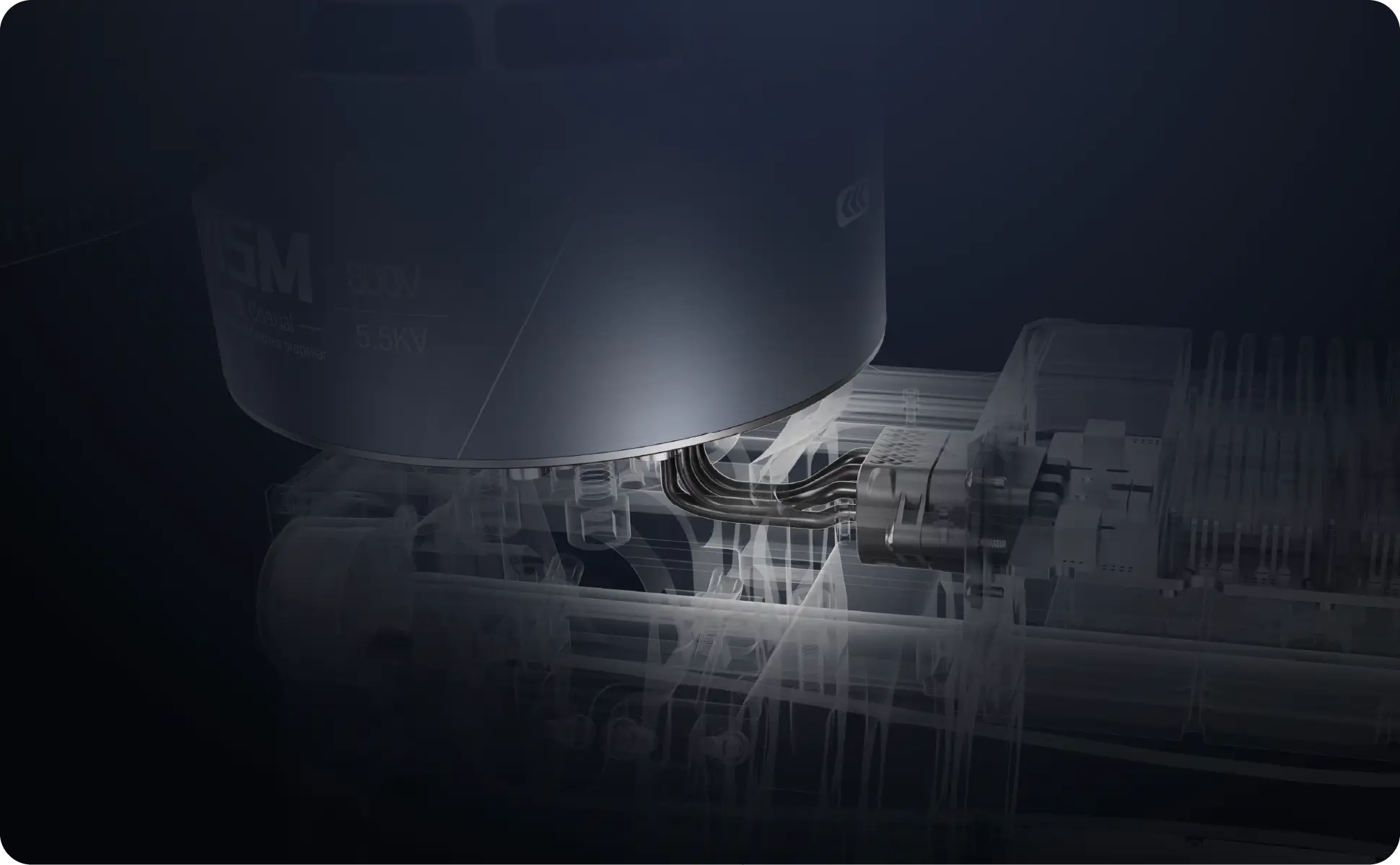

Innovative Design

- Highly integrated design

- At 800V and over 100kg-class thrust, the motor, ESC, and propeller are fully integrated in a groundbreaking design that eliminates exposed cables. This streamlines the entire wiring layout, drastically reduces installation complexity and maintenance costs, and eliminates failures from cable tension, abrasion, or short circuits at the source. Significantly Enhancing Overall System Reliability.

- Ultra-short wiring

- Shortened Three-Phase Cables minimizes transmission losses and EMI from long runs. Delivering Higher System Efficiency, Superior Stability, and Cleaner power Performance.

- All built-in connections

- All wiring placed inside durable carbon tubes to resist aging, moisture ingress, salt spray corrosion, and dust. Ensuring extended, maintenance-free lifespan in demanding applications.

- Innovative patented internal support design for tube clip holder

- The patented internal support structure effectively suppresses vibration and displacement of arms under heavy-lift conditions, ensuring continuous, stable, and reliable propulsion output. Compatible with arm thicknesses ranging from 2 mm to 5 mm, accommodating a wide variety of materials and manufacturing processes for maximum integration flexibility.

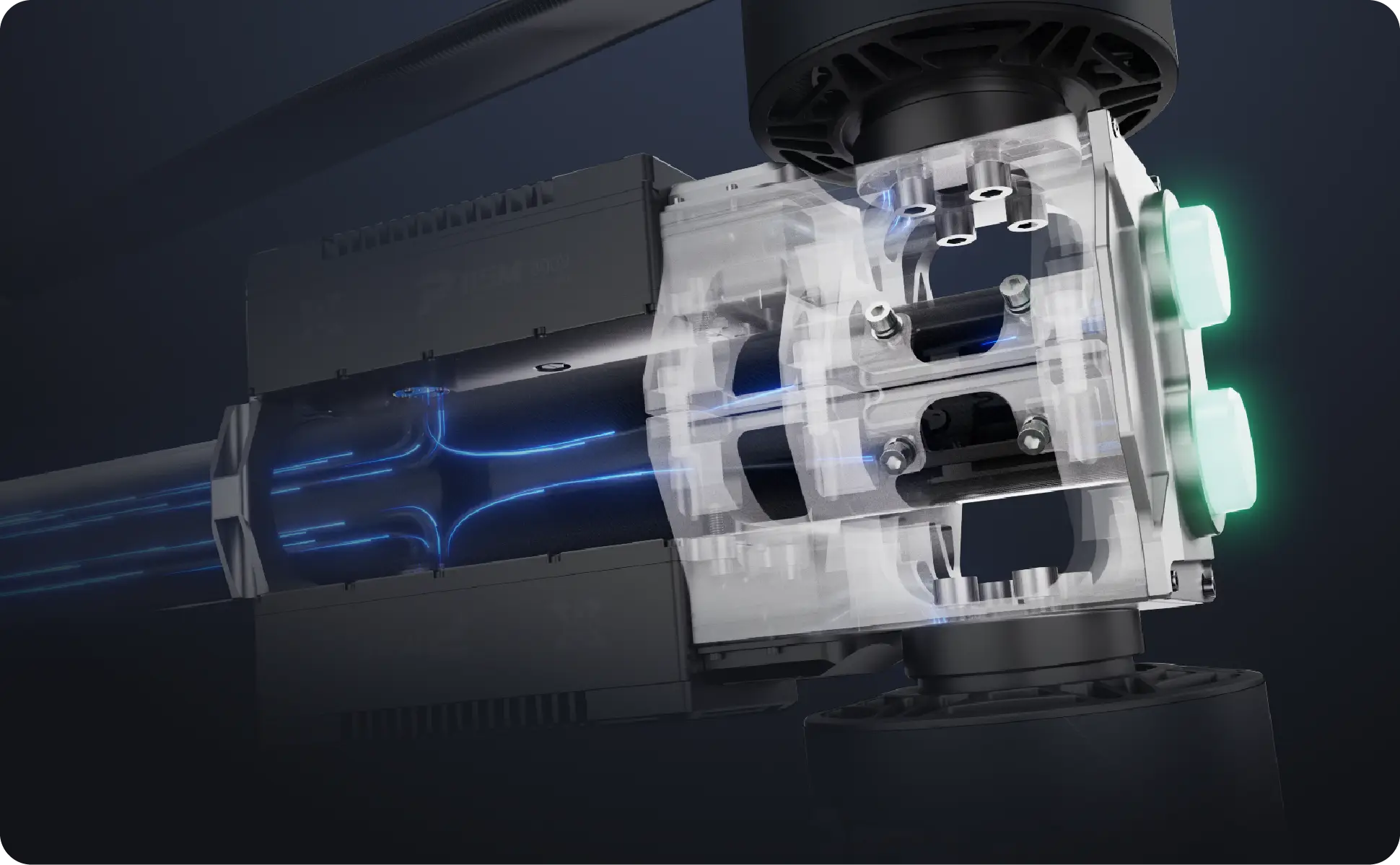

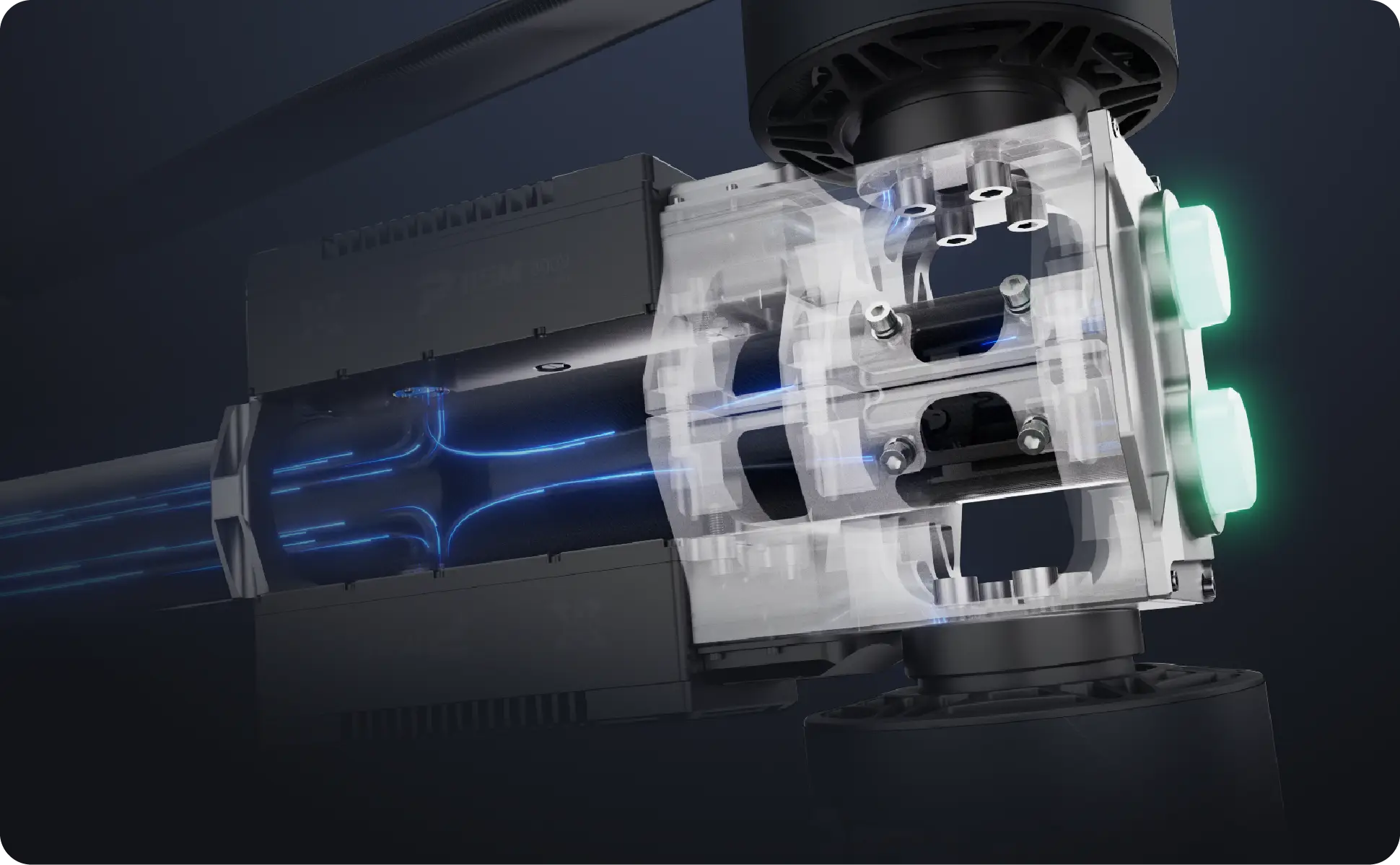

Efficient Energy-Saving

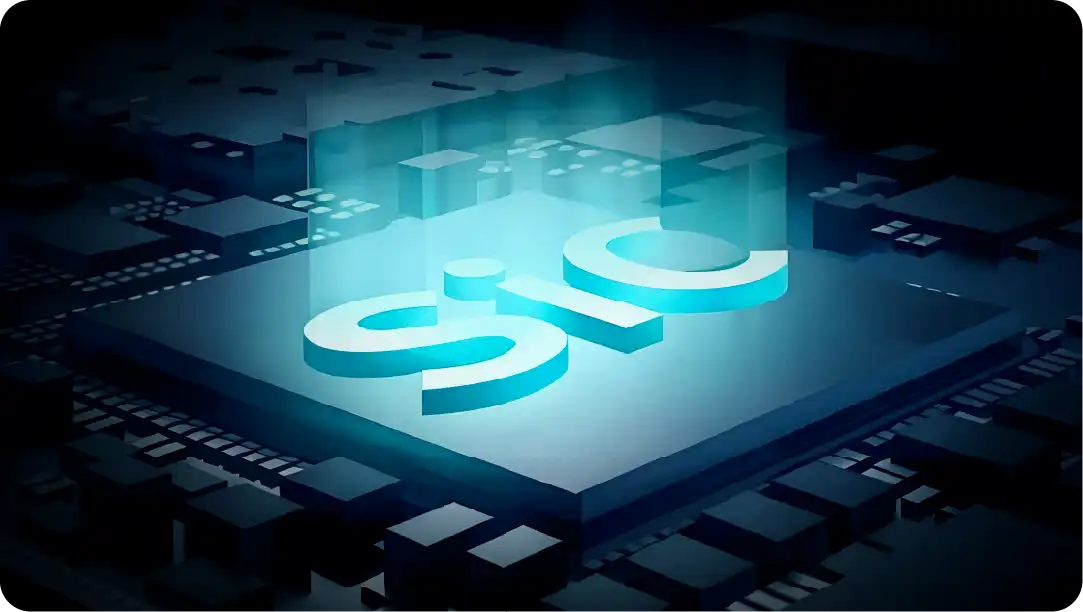

Supports 850V DC input, reaching the top

Supports 850V DC input, reaching the top industrial standard.

At the same power level, transmission current is significantly reduced, minimizing energy losses, allowing thinner and lighter cables, and substantially increasing overall power density.

Equipped with cutting-edge third-generation automotive-grade SiC MOSFETs, the system achieves ultra-low switching losses and a substantial boost in overall efficiency. Ideal for demanding, mission-critical applications such as firefighting, cargo transport, and heavy-lift industrial operations.

Equipped with cutting-edge third-generation automotive-grade SiC MOSFETs, the system achieves ultra-low switching losses and a substantial boost in overall efficiency. Ideal for demanding, mission-critical applications such as firefighting, cargo transport, and heavy-lift industrial operations.Flexible Adaptation

Compatible with D60 and D80 arm mount methods,

the product supports both flat and coaxial layouts,

and offers 64-inch and 73-inch quick-release carbon fiber propellers,

meeting the overall size requirements.

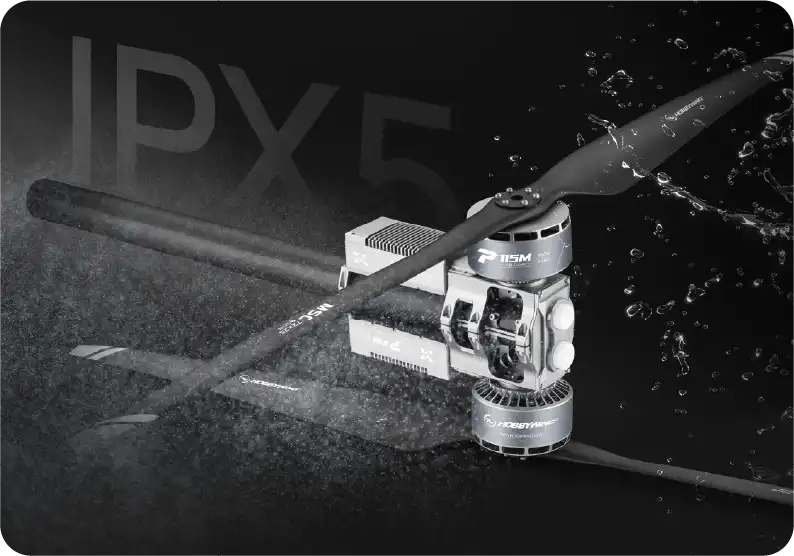

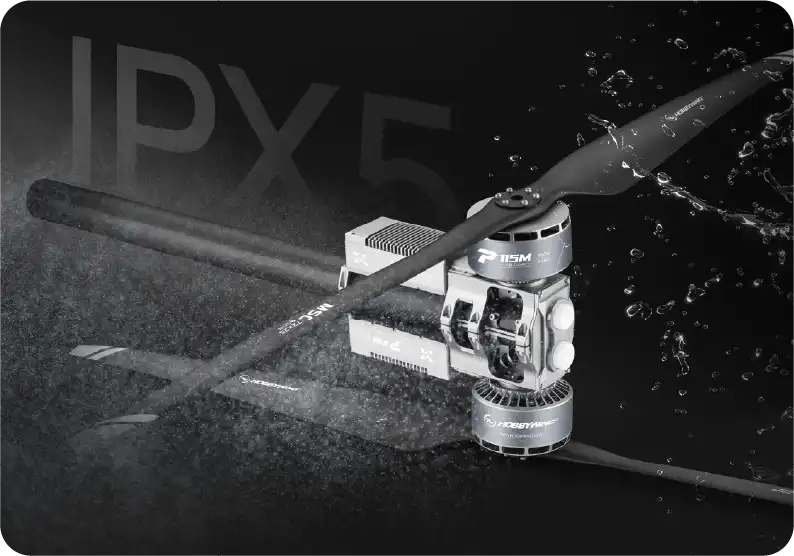

Ready for Harsh Environments

The motor features high-temperature resistant enameled wires rated up to 200°C, an IPX5

protection rating, and insulation capable of withstanding up to 2,700V. The system’s internal potting

process provides robust protection against high temperatures, humidity, and firefighting powders.

up to

200℃

IPX5

2700V

High-temperature

High-temperatureresistant enameled wires

Designs for a Safer Flight

The product boasts dual-mode operation with sensorless FOC as the primary

control and sensor FOC as backup for enhanced safety. Two sets of signal channels

can be converted in real time to enhance the reliability of the propulsion system./p>

The dual heterogeneous communication links via CAN bus and RS485 are supported.

Speed information is obtained in real time through dual channels to meet airworthiness

certification requirements and flexibly respond to future regulatory requirements.

Three throttle combination methods are supported

- PWM+CAN digital throttle

- is the default configuration

- PWM+RS485

- is optional

- CAN+RS485

- is optional

Adapts seamlessly to the communication needs of various flight controllers, enabling real-time

upload of critical flight data and continuous monitoring of key parameters.

(RPM, Throttle Position, Current, Voltage, and Temperature)

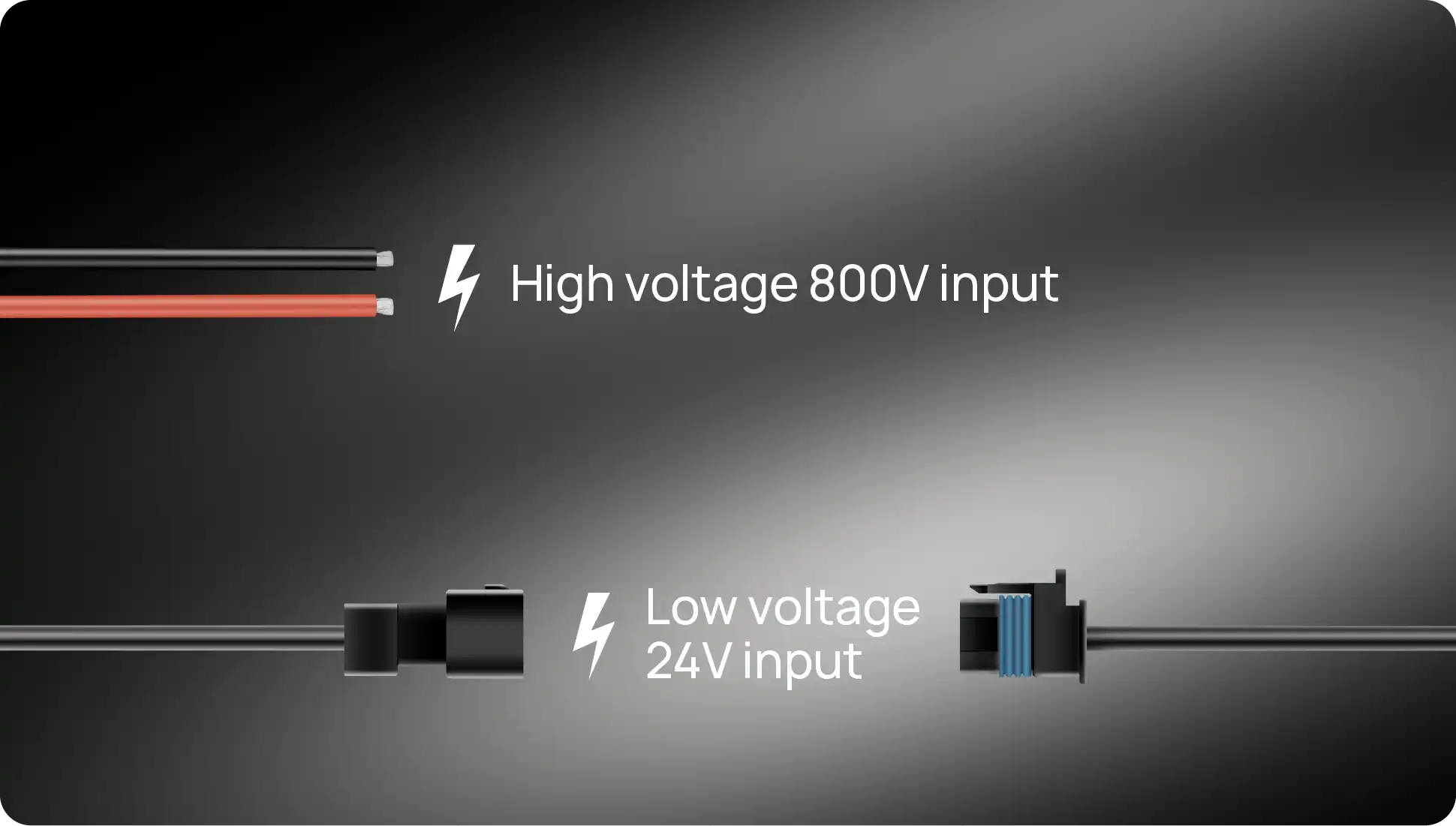

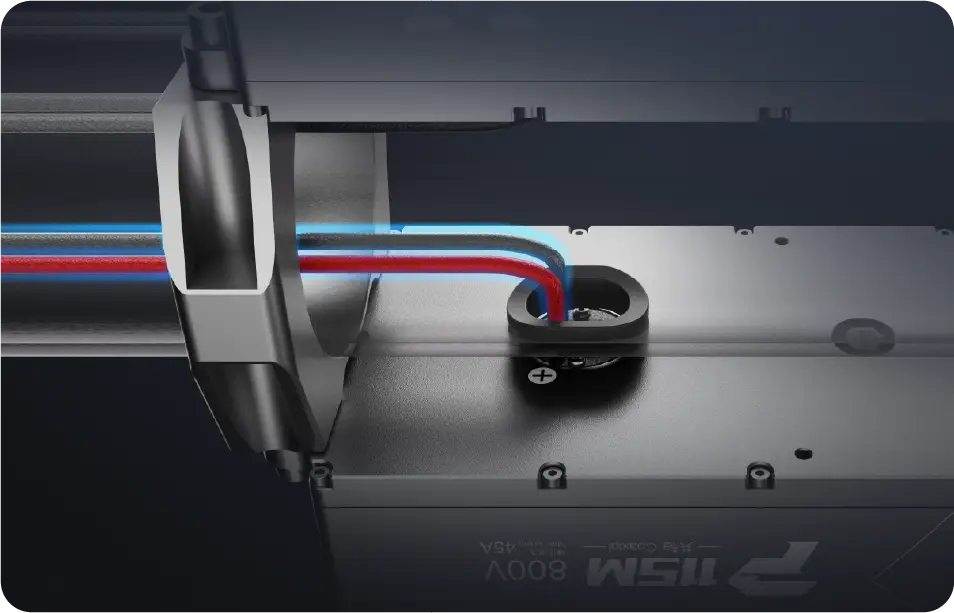

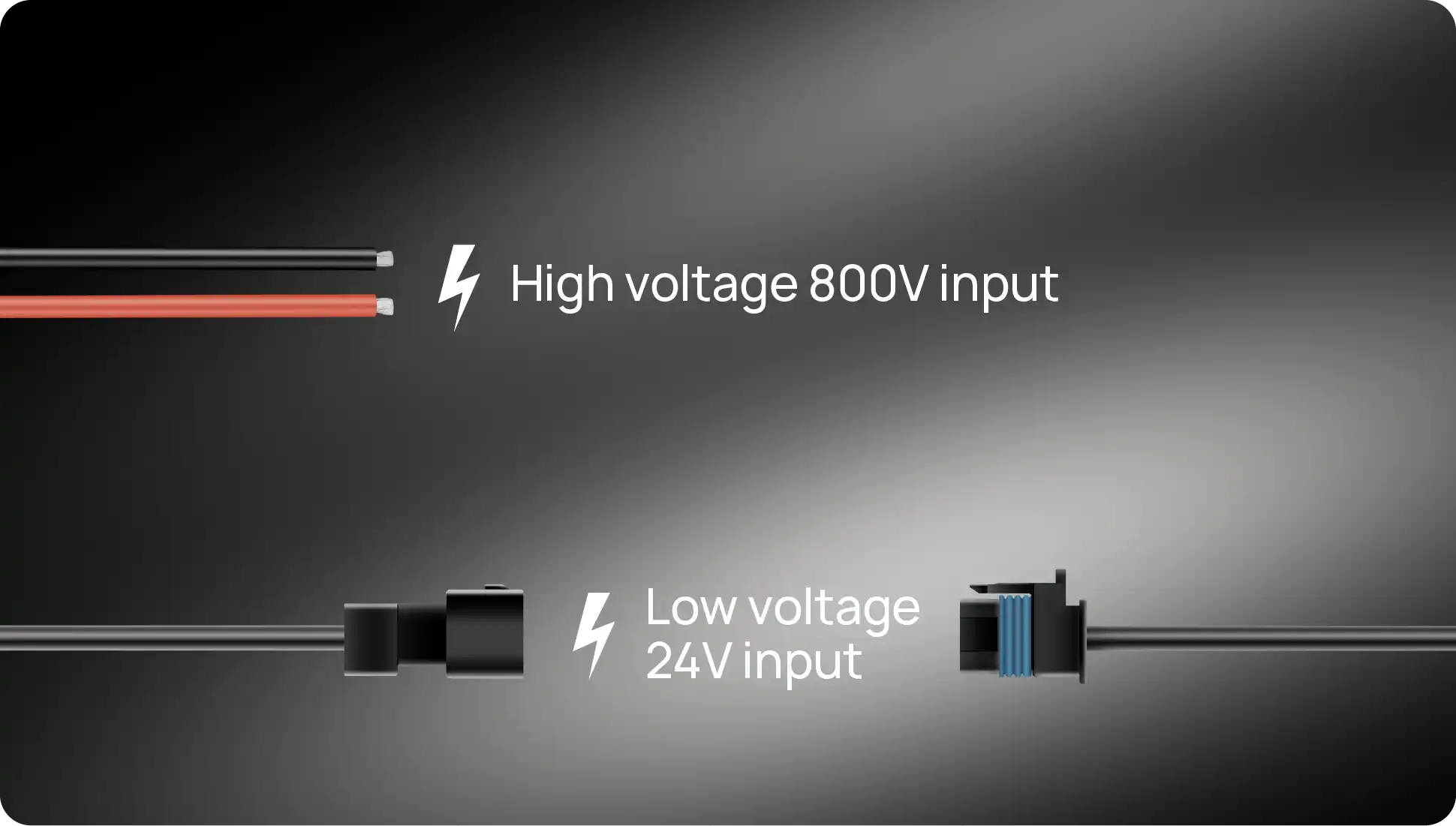

In addition to conventional high‑voltage input, it also supports an

independent high and low voltage power distribution method (with low

voltage at 24V). Both power distribution schemes are fully compatible.

Automotive-Grade Materials

Automotive-Grade System Design

- The software

- adopts a rigorous modular design.

- The hardware

- system implements a fully isolated architecture, separating high-voltage power circuits, low-voltage signal circuits, and protective earthing (PE). This ensures reliable data transmission, stable equipment operation, and significantly enhanced safety for both personnel and connected systems.

- Structural

design - High-

specification

materials - Tilt design

of the tube

clip holder

enhances effective payload space. In addition, the product features a

sleek and streamlined design with no exposed cables.

high-temperature-resistant materials, propellers are made of carbon fiber materials

with higher reliability, and connectors adopt automotive-grade materials, which are

foolproof, anti-false connection and vibration-resistant, providing reliable system

connection and extended service life.

hovering stability, and maneuverability, easily adaptable to various flight controllers.

Throttle loss

Throttle losswarning

Reverse polarity

Reverse polarityprotection

Undervoltage

Undervoltagewarning

Overvoltage

Overvoltagewarning

Overcurrent

Overcurrentprotection

Over-temperature

Over-temperaturewarning

Motor stall

Motor stallprotection

Motor overspeed

Motor overspeedprotection

Fail to reset throttle

Fail to reset throttleto zero protection

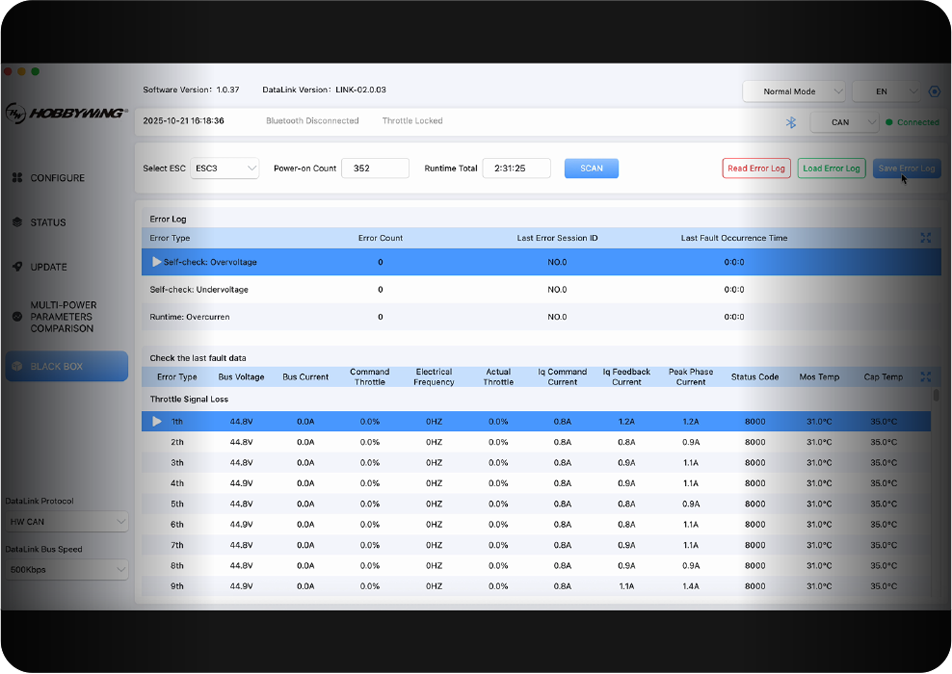

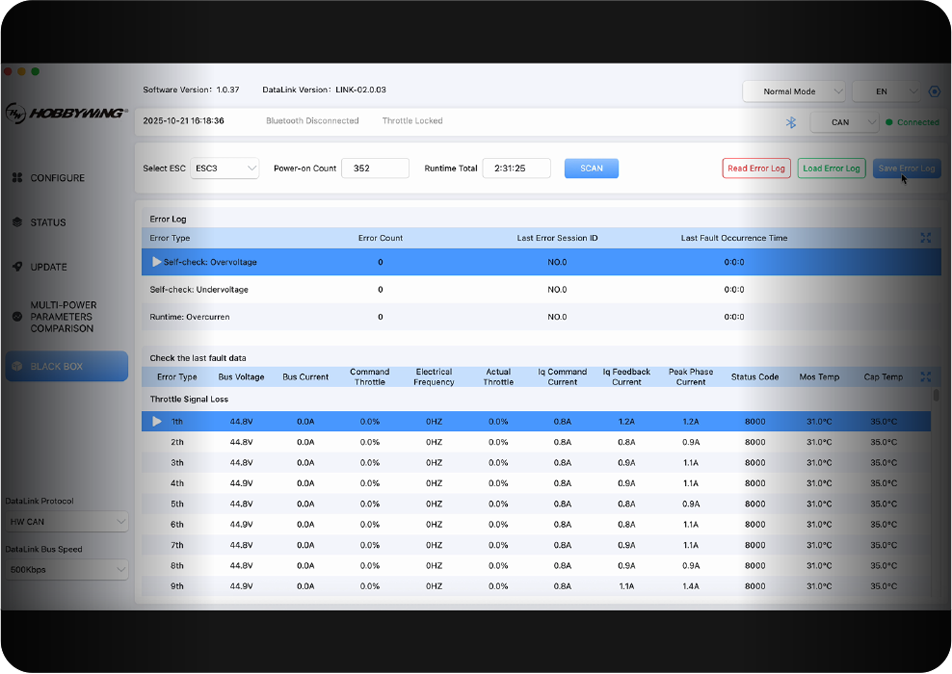

can record fault codes during

operation, making it easier to

accurately trace the cause.

Real-time recording of UAV operation

data within 2-48 hours facilitates

subsequent data analysis.

captures real-time operational

data with milliseconds, allowing

for traceability and analysis.

and Firmware OTA Upgrade

With HOBBYWING’s proprietary host computer software, users can adjust drive

parameters, motor rotation direction, and light color (default green) effortlessly based on

application requirements to optimize flight performance and upgrade the latest firmware.

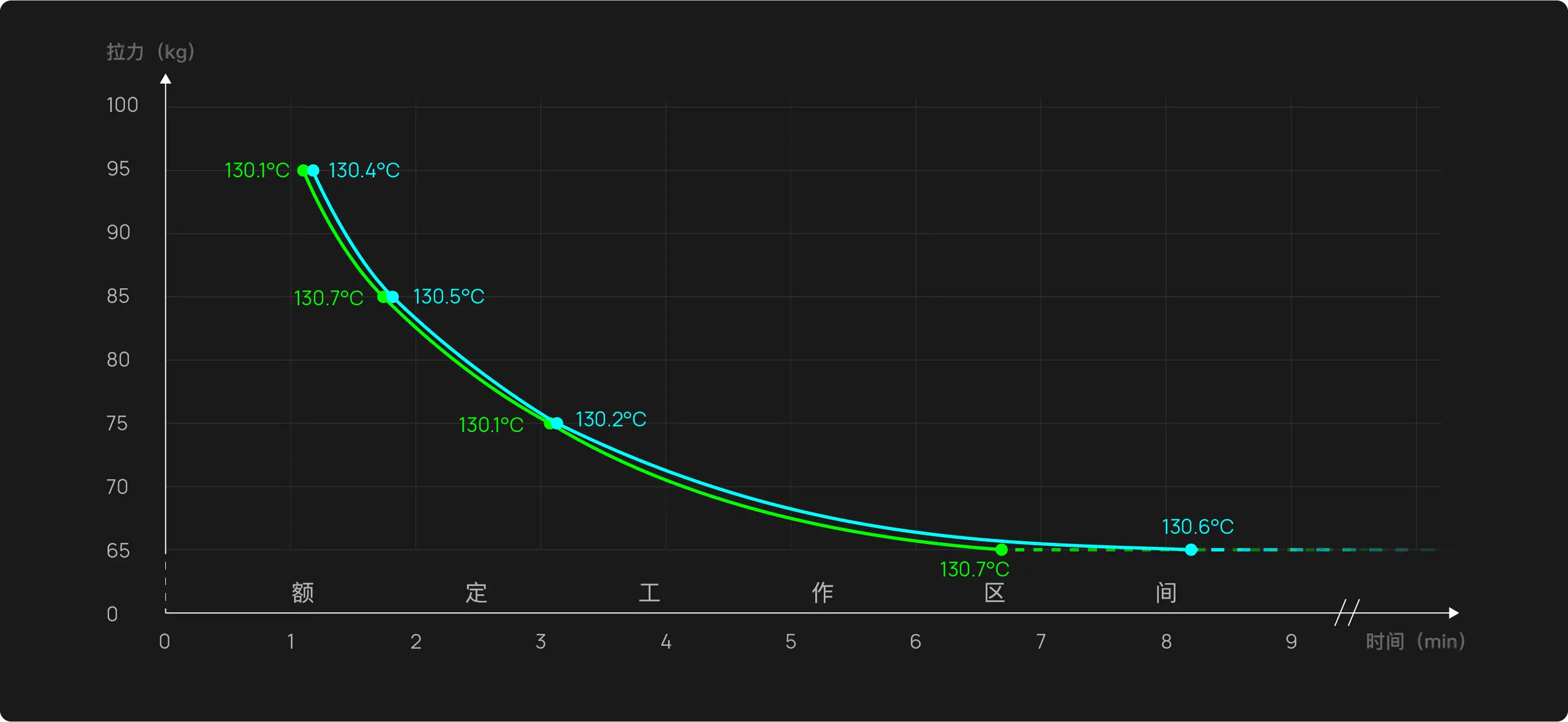

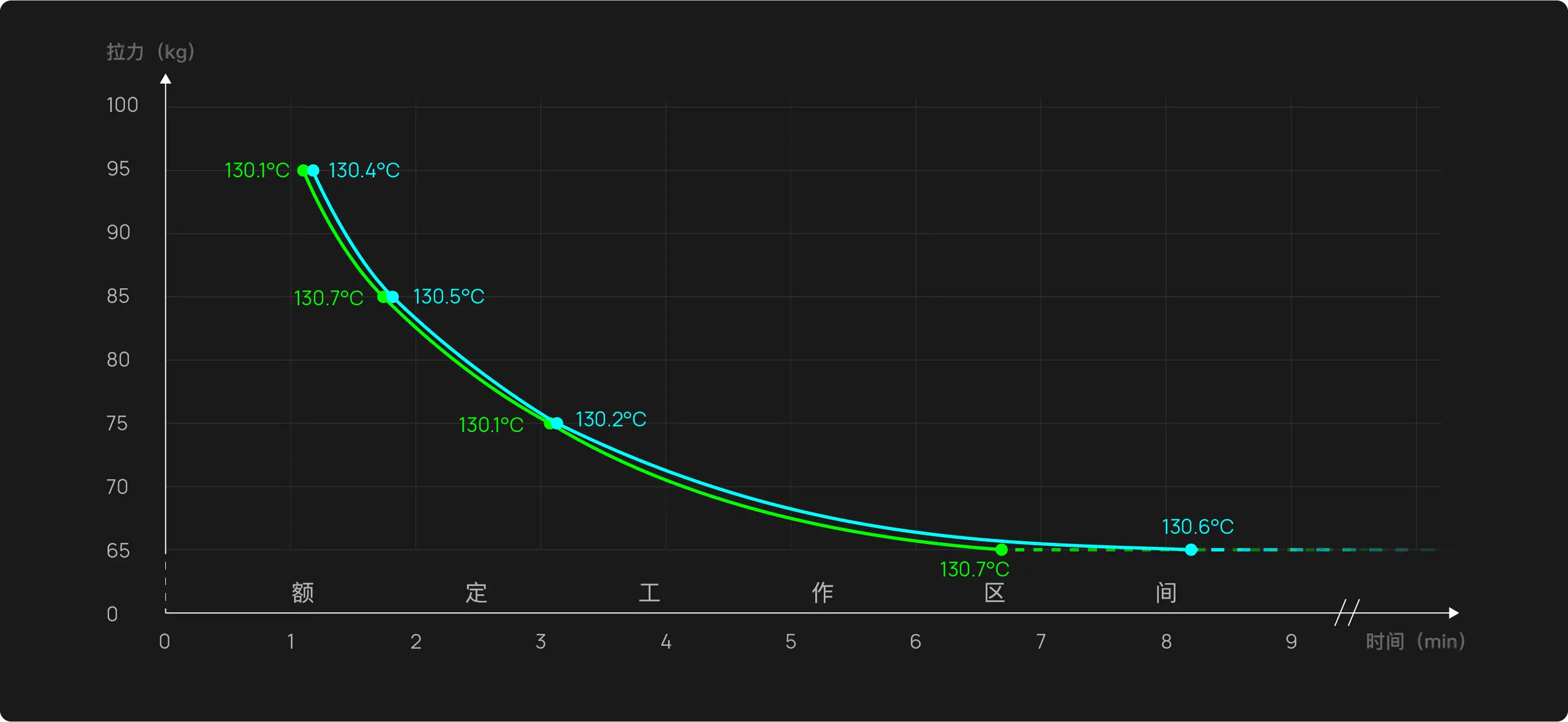

- *he above data provides the maximum permissible temperature values for each overload point, measured under optimal conditions: effective heat dissipation, an ambient temperature of 25°C, sea-level altitude, and consistent rotational speed.

- The horizontal axis (time) represents the maximum safe operating duration for each overload point under the stated conditions. Exceeding this duration during actual flight may cause irreversible damage to the propulsion system due to overheating.

- Please note: To prioritize flight safety, the propulsion system will not automatically shut down. Therefore, strict monitoring is required to avoid overloading beyond the specified time limits.

-

-

Thank you for your interest in HOBBYWING propulsion systems! For customized solutions,

please provide your contact information and technical requirements,

and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

- MSC 64x23-P

- MSC 73x21-P (Coming soon)

-

- Model

- Max Thrust

- Rated thrust

- System efficiency

- Input voltage

- Rated voltage

- Tube outer diameter

- Weight(with cable and Props)

- Cable specification

- Operating temperature

- Ingress protection

- Rated power input(single motor)

- Rated power output(single motor)

- Signal cable define

-

- P115M

- 232 kg

- 115 kg

- 5.4 g/W

- 500~850V

- 720 V

- Φ80mm(Wall thickness varies by material, ends require specific holes. See specs.)

- 19.7 kg ± 50 g

- Power cable:12AWG*2000 mm Signal cable:2200 mm

- -35~55 ℃

- IP35

- 10608 W

- 9121 W

- Blue-CAN-GND、Red-CANH,Brown-CANL、Black-Shielded、Green-PWM、,Gray-PWM-GND、Orange-DC24V+、Yellow-DC24V-

- P115M

- 240 kg

- 115 kg

- Coming soon

- 500~850V

- 720 V

- Φ80mm(Wall thickness varies by material, ends require specific holes. See specs.)

- Coming soon

- Power cable:12AWG*2000 mm Signal cable:2200 mm

- -35~55 ℃

- IP35

- Coming soon

- Coming soon

- Blue-CAN-GND、Red-CANH,Brown-CANL、Black-Shielded、Green-PWM、,Gray-PWM-GND、Orange-DC24V+、Yellow-DC24V-

-

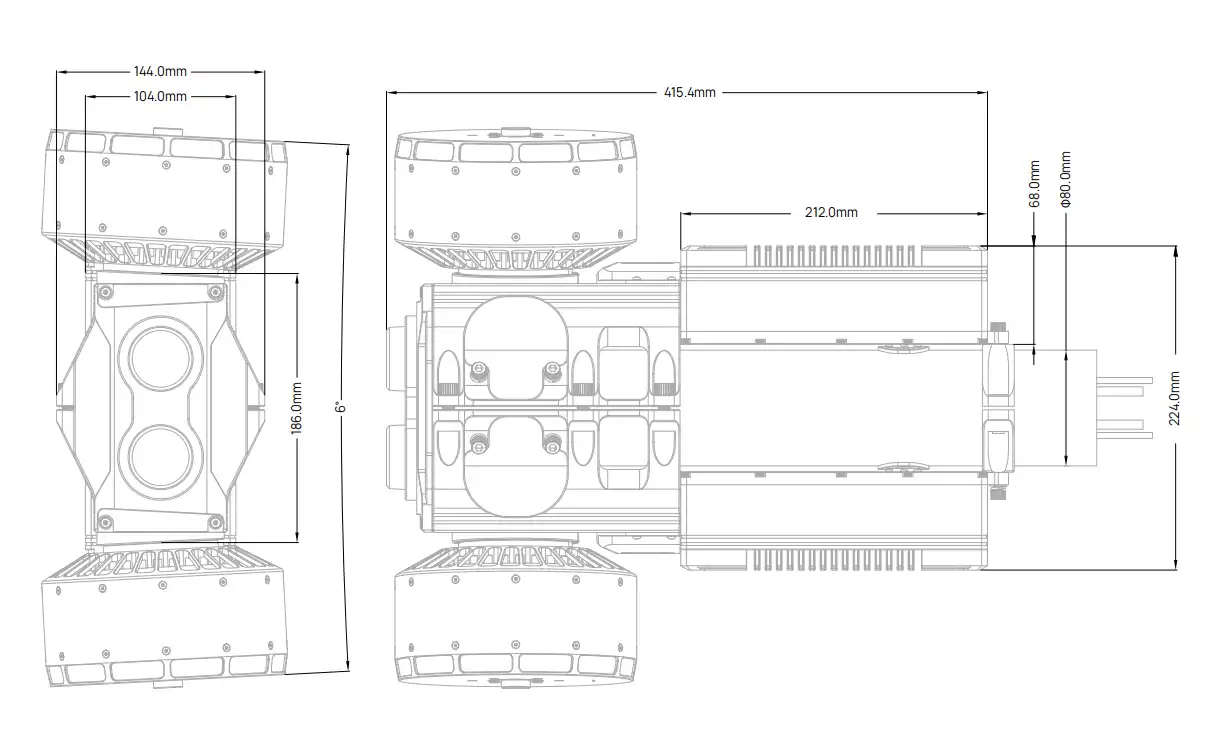

- Rated voltage

- Communication protocol

- ESC size

- Weight(with cable)

- Peak current (10 seconds)

- Continuous current

- Ingress Protection

- Double throttle signal

- Operating pulse width(Not supported)

- Black box

-

- 720 V

- CAN(customizable RS485)

- 211 mm*104 mm*67 mm(Without plug)

- 1880±50 g

- 45 A

- 15 A

- IP67

- CAN+RS485 / CAN+PWM / RS485+PWM

- 1100~1940 μs

- 2~48h log

- 720 V

- CAN(customizable RS485)

- 211 mm*104 mm*67 mm(Without plug)

- 1880±50 g

- 45 A

- 15 A

- IP67

- CAN+RS485 / CAN+PWM / RS485+PWM

- 1100~1940 μs

- 2~48h log

-

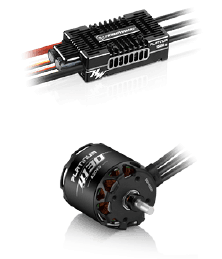

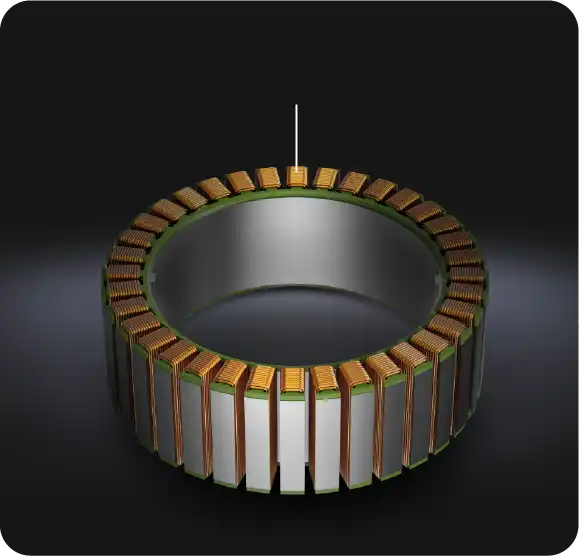

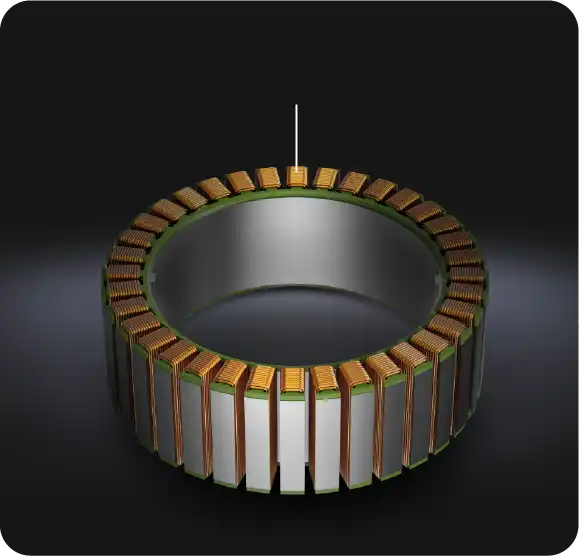

- Stator size

- KV

- Motor diameter

- Slot& Pole

- Ingress Protection

- Weight(with cable)

-

- 156*50 mm

- 5.5 KV

- Φ167.1±0.1 mm

- 36N42P

- IPX5

- 5172 g

- Coming soon

- Coming soon

- Coming soon

- Coming soon

- Coming soon

- Coming soon

-

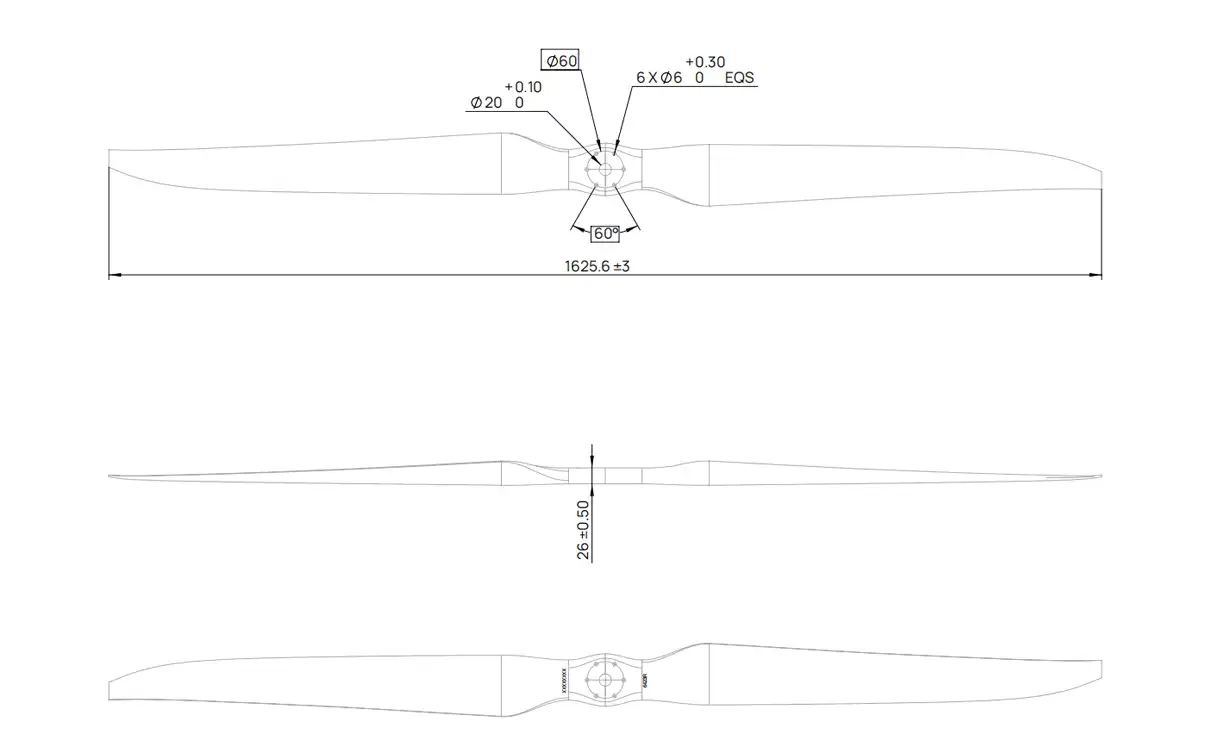

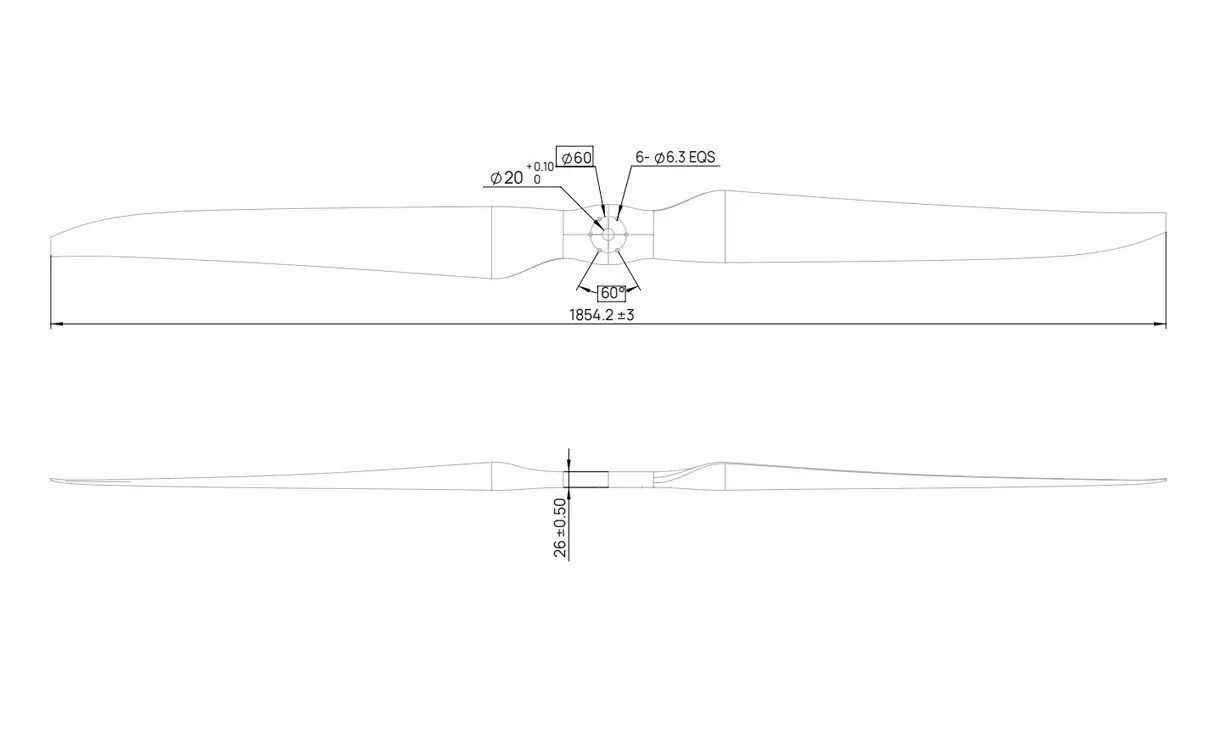

- Model

- Weight

- Material of Props

- Mounting dimensions

-

- MSC 64x23-P

- 1035 ±20g

- Carbon unfolding Props

- D60-6*M6, centre hole D20

- MSC 73x21-P

- Coming soon

- Carbon unfolding Props

- Coming soon

|

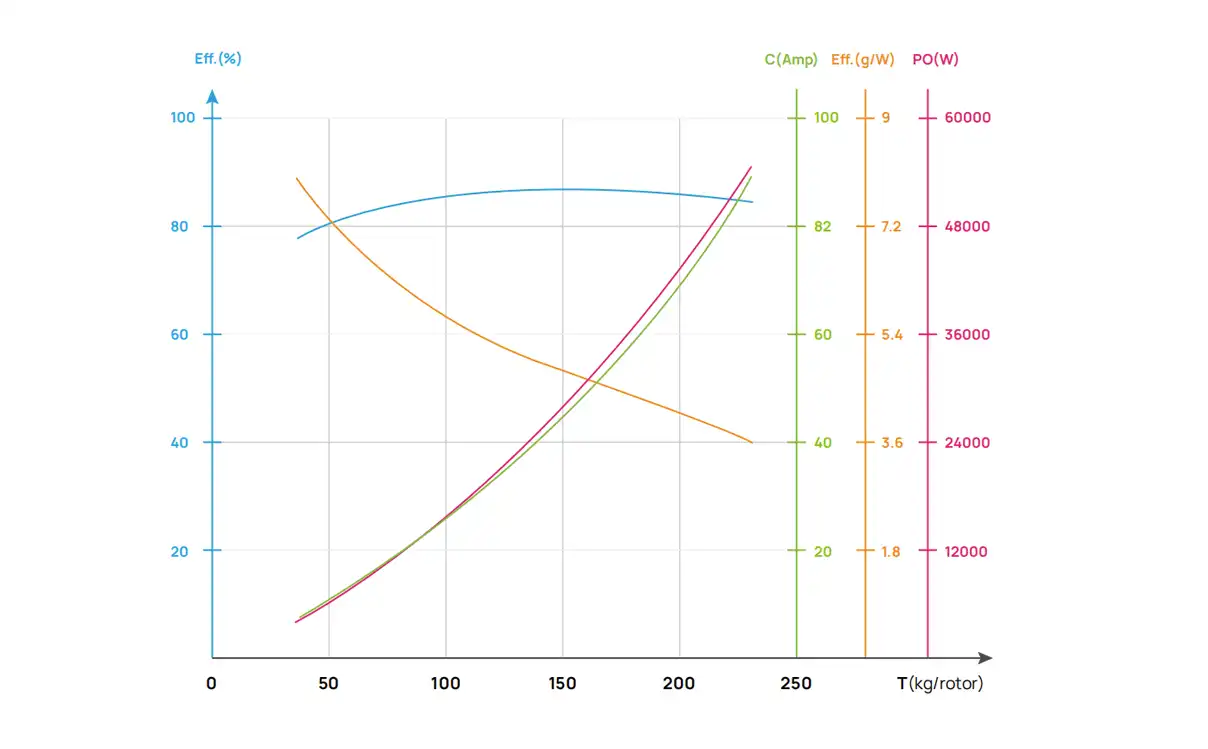

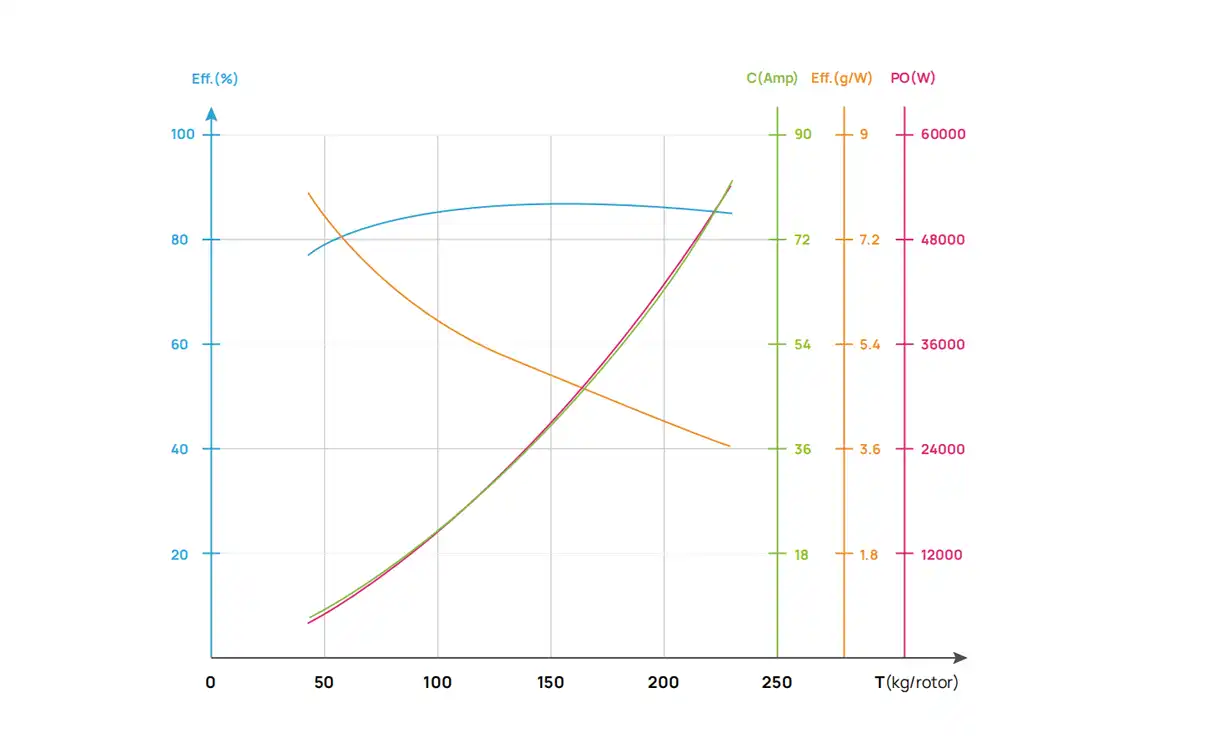

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Efficiency(%) |

Efficiency(g/W) |

Power Output(W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|

|

780V |

MSC 64x23-P |

38% |

63322 |

11.6 |

9024.6 |

81.50 |

7.0 |

7355.0 |

/ |

|

40% |

70468 |

13.4 |

10467.6 |

82.50 |

6.7 |

8635.8 |

|||

|

42% |

77776 |

15.4 |

12019.8 |

83.32 |

6.5 |

10014.9 |

|||

|

44% |

85222 |

17.5 |

13681.2 |

84.00 |

6.2 |

11492.2 |

|||

|

46% |

92781 |

19.8 |

15436.2 |

84.56 |

6.0 |

13052.9 |

|||

|

48% |

100426 |

22.2 |

17292.6 |

85.03 |

5.8 |

14703.9 |

|||

|

50% |

108132 |

24.7 |

19227.0 |

85.43 |

5.6 |

16425.6 |

|||

|

52% |

115873 |

27.2 |

21231.6 |

85.76 |

5.5 |

18208.2 |

|||

|

54% |

123621 |

29.9 |

23306.4 |

86.03 |

5.3 |

20050.5 |

|||

|

56% |

131349 |

32.6 |

25451.4 |

86.25 |

5.2 |

21951.8 |

|||

|

58% |

139029 |

35.4 |

27643.2 |

86.43 |

5.0 |

23892.0 |

|||

|

60% |

146630 |

38.3 |

29889.6 |

86.57 |

4.9 |

25875.4 |

|||

|

62% |

154125 |

41.3 |

32175.0 |

86.66 |

4.8 |

27882.9 |

|||

|

64% |

161481 |

44.2 |

34499.4 |

86.71 |

4.7 |

29914.4 |

|||

|

66% |

168669 |

47.3 |

36855.0 |

86.72 |

4.6 |

31960.7 |

|||

|

68% |

175656 |

50.3 |

39241.8 |

86.69 |

4.5 |

34018.7 |

|||

|

70% |

182409 |

53.4 |

41636.4 |

86.62 |

4.4 |

36065.4 |

|||

|

72% |

188895 |

56.5 |

44046.6 |

86.53 |

4.3 |

38113.5 |

|||

|

76% |

200925 |

62.6 |

48804.6 |

86.24 |

4.1 |

42089.1 |

|||

|

80% |

211457 |

68.4 |

53344.2 |

85.89 |

4.0 |

45817.3 |

|||

|

85% |

222052 |

74.8 |

58328.4 |

85.42 |

3.8 |

49824.1 |

|||

|

100% |

232212 |

81.5 |

63546.6 |

84.87 |

3.7 |

53932.0 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.

Innovative Design

- At 800V and over 100kg-class thrust, the motor, ESC, and propeller are fully integrated in a groundbreaking design that

eliminates exposed cables. This streamlines the entire wiring layout, drastically reduces installation complexity and

maintenance costs, and eliminates failures from cable tension, abrasion, or short circuits at the source.

Significantly Enhancing Overall System Reliability.

- Shortened Three-Phase Cables minimizes transmission losses and EMI from long runs.

Delivering Higher System Efficiency, Superior Stability, and Cleaner power Performance.

- All wiring placed inside durable carbon tubes to resist aging, moisture ingress, salt spray corrosion, and dust.

Ensuring extended, maintenance-free lifespan in demanding applications.

- The patented internal support structure effectively suppresses vibration and displacement of

arms under heavy-lift conditions, ensuring continuous, stable, and reliable propulsion output.

Compatible with arm thicknesses ranging from 2 mm to 5 mm, accommodating a wide variety

of materials and manufacturing processes for maximum integration flexibility.

- Highly integrated design

- Ultra-short wiring

- All built-in connections

- Innovative patented internal support design for tube clip holder

Innovative Design

- Highly integrated design

- At 800V and over 100kg-class thrust, the motor, ESC, and propeller are fully integrated in a groundbreaking design that eliminates exposed cables. This streamlines the entire wiring layout, drastically reduces installation complexity and maintenance costs, and eliminates failures from cable tension, abrasion, or short circuits at the source. Significantly Enhancing Overall System Reliability.

- Ultra-short wiring

- Shortened Three-Phase Cables minimizes transmission losses and EMI from long runs. Delivering Higher System Efficiency, Superior Stability, and Cleaner power Performance.

- All built-in connections

- All wiring placed inside durable carbon tubes to resist aging, moisture ingress, salt spray corrosion, and dust. Ensuring extended, maintenance-free lifespan in demanding applications.

- Innovative patented internal support design for tube clip holder

- The patented internal support structure effectively suppresses vibration and displacement of arms under heavy-lift conditions, ensuring continuous, stable, and reliable propulsion output. Compatible with arm thicknesses ranging from 2 mm to 5 mm, accommodating a wide variety of materials and manufacturing processes for maximum integration flexibility.

Efficient Energy-Saving

Supports 850V DC input, reaching the top

Supports 850V DC input, reaching the top industrial standard.

At the same power level, transmission current is significantly reduced, minimizing energy losses, allowing thinner and lighter cables, and substantially increasing overall power density.

Equipped with cutting-edge third-generation automotive-grade SiC MOSFETs, the system achieves ultra-low switching losses and a substantial boost in overall efficiency. Ideal for demanding, mission-critical applications such as firefighting, cargo transport, and heavy-lift industrial operations.

Equipped with cutting-edge third-generation automotive-grade SiC MOSFETs, the system achieves ultra-low switching losses and a substantial boost in overall efficiency. Ideal for demanding, mission-critical applications such as firefighting, cargo transport, and heavy-lift industrial operations.Flexible Adaptation

Compatible with D60 and D80 arm mount methods,

the product supports both flat and coaxial layouts,

and offers 64-inch and 73-inch quick-release carbon fiber propellers,

meeting the overall size requirements.

Ready for Harsh Environments

The motor features high-temperature resistant enameled wires rated up to 200°C, an IPX5

protection rating, and insulation capable of withstanding up to 2,700V. The system’s internal potting

process provides robust protection against high temperatures, humidity, and firefighting powders.

up to

200℃

IPX5

2700V

High-temperature

High-temperatureresistant enameled wires

Designs for a Safer Flight

The product boasts dual-mode operation with sensorless FOC as the primary

control and sensor FOC as backup for enhanced safety. Two sets of signal channels

can be converted in real time to enhance the reliability of the propulsion system./p>

The dual heterogeneous communication links via CAN bus and RS485 are supported.

Speed information is obtained in real time through dual channels to meet airworthiness

certification requirements and flexibly respond to future regulatory requirements.

Three throttle combination methods are supported

- PWM+CAN digital throttle

- is the default configuration

- PWM+RS485

- is optional

- CAN+RS485

- is optional

Adapts seamlessly to the communication needs of various flight controllers, enabling real-time

upload of critical flight data and continuous monitoring of key parameters.

(RPM, Throttle Position, Current, Voltage, and Temperature)

In addition to conventional high‑voltage input, it also supports an

independent high and low voltage power distribution method (with low

voltage at 24V). Both power distribution schemes are fully compatible.

Automotive-Grade Materials

Automotive-Grade System Design

- The software

- adopts a rigorous modular design.

- The hardware

- system implements a fully isolated architecture, separating high-voltage power circuits, low-voltage signal circuits, and protective earthing (PE). This ensures reliable data transmission, stable equipment operation, and significantly enhanced safety for both personnel and connected systems.

- Structural

design - High-

specification

materials - Tilt design

of the tube

clip holder

enhances effective payload space. In addition, the product features a

sleek and streamlined design with no exposed cables.

high-temperature-resistant materials, propellers are made of carbon fiber materials

with higher reliability, and connectors adopt automotive-grade materials, which are

foolproof, anti-false connection and vibration-resistant, providing reliable system

connection and extended service life.

hovering stability, and maneuverability, easily adaptable to various flight controllers.

Throttle loss

Throttle losswarning

Reverse polarity

Reverse polarityprotection

Undervoltage

Undervoltagewarning

Overvoltage

Overvoltagewarning

Overcurrent

Overcurrentprotection

Over-temperature

Over-temperaturewarning

Motor stall

Motor stallprotection

Motor overspeed

Motor overspeedprotection

Fail to reset throttle

Fail to reset throttleto zero protection

can record fault codes during

operation, making it easier to

accurately trace the cause.

Real-time recording of UAV operation

data within 2-48 hours facilitates

subsequent data analysis.

captures real-time operational

data with milliseconds, allowing

for traceability and analysis.

and Firmware OTA Upgrade

With HOBBYWING’s proprietary host computer software, users can adjust drive

parameters, motor rotation direction, and light color (default green) effortlessly based on

application requirements to optimize flight performance and upgrade the latest firmware.

- *he above data provides the maximum permissible temperature values for each overload point, measured under optimal conditions: effective heat dissipation, an ambient temperature of 25°C, sea-level altitude, and consistent rotational speed.

- The horizontal axis (time) represents the maximum safe operating duration for each overload point under the stated conditions. Exceeding this duration during actual flight may cause irreversible damage to the propulsion system due to overheating.

- Please note: To prioritize flight safety, the propulsion system will not automatically shut down. Therefore, strict monitoring is required to avoid overloading beyond the specified time limits.

-

- Thank you for your interest in HOBBYWING propulsion systems! For customized solutions, please provide your contact information and technical requirements, and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

- MSC 64x23-P

- MSC 73x21-P (Coming soon)

-

- Model

- Max Thrust

- Rated thrust

- System efficiency

- Input voltage

- Rated voltage

- Tube outer diameter

- Weight(with cable and Props)

- Cable specification

- Operating temperature

- Ingress protection

- Rated power input(single motor)

- Rated power output(single motor)

- Signal cable define

-

- P115M

- 232 kg

- 115 kg

- 5.4 g/W

- 500~850V

- 720 V

- Φ80mm(Wall thickness varies by material, ends require specific holes. See specs.)

- 19.7 kg ± 50 g

- Power cable:12AWG*2000 mm Signal cable:2200 mm

- -35~55 ℃

- IP35

- 10608 W

- 9121 W

- Blue-CAN-GND、Red-CANH,Brown-CANL、Black-Shielded、Green-PWM、,Gray-PWM-GND、Orange-DC24V+、Yellow-DC24V-

- P115M

- 240 kg

- 115 kg

- Coming soon

- 500~850V

- 720 V

- Φ80mm(Wall thickness varies by material, ends require specific holes. See specs.)

- Coming soon

- Power cable:12AWG*2000 mm Signal cable:2200 mm

- -35~55 ℃

- IP35

- Coming soon

- Coming soon

- Blue-CAN-GND、Red-CANH,Brown-CANL、Black-Shielded、Green-PWM、,Gray-PWM-GND、Orange-DC24V+、Yellow-DC24V-

-

- Rated voltage

- Communication protocol

- ESC size

- Weight(with cable)

- Peak current (10 seconds)

- Continuous current

- Ingress Protection

- Double throttle signal

- Operating pulse width(Not supported)

- Black box

-

- 720 V

- CAN(customizable RS485)

- 211 mm*104 mm*67 mm(Without plug)

- 1880±50 g

- 45 A

- 15 A

- IP67

- CAN+RS485 / CAN+PWM / RS485+PWM

- 1100~1940 μs

- 2~48h log

- 720 V

- CAN(customizable RS485)

- 211 mm*104 mm*67 mm(Without plug)

- 1880±50 g

- 45 A

- 15 A

- IP67

- CAN+RS485 / CAN+PWM / RS485+PWM

- 1100~1940 μs

- 2~48h log

-

- Stator size

- KV

- Motor diameter

- Slot& Pole

- Ingress Protection

- Weight(with cable)

-

- 156*50 mm

- 5.5 KV

- Φ167.1±0.1 mm

- 36N42P

- IPX5

- 5172 g

- Coming soon

- Coming soon

- Coming soon

- Coming soon

- Coming soon

- Coming soon

-

- Model

- Weight

- Material of Props

- Mounting dimensions

-

- MSC 64x23-P

- 1035 ±20g

- Carbon unfolding Props

- D60-6*M6, centre hole D20

- MSC 73x21-P

- Coming soon

- Carbon unfolding Props

- Coming soon

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Efficiency(%) |

Efficiency(g/W) |

Power Output(W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|

|

720V |

MSC 64x23-P |

38% |

63370 |

12.5 |

9007.2 |

82.10 |

7.0 |

7394.9 |

/ |

|

40% |

70510 |

14.5 |

10440.0 |

83.09 |

6.8 |

8674.6 |

|||

|

42% |

77805 |

16.6 |

11980.8 |

83.92 |

6.5 |

10054.3 |

|||

|

44% |

85235 |

18.9 |

13629.6 |

84.60 |

6.3 |

11530.6 |

|||

|

46% |

92777 |

21.4 |

15372.0 |

85.17 |

6.0 |

13092.3 |

|||

|

48% |

100409 |

23.9 |

17215.2 |

85.62 |

5.8 |

14739.7 |

|||

|

50% |

108106 |

26.6 |

19144.8 |

86.00 |

5.6 |

16464.5 |

|||

|

52% |

115840 |

29.4 |

21153.6 |

86.30 |

5.5 |

18255.6 |

|||

|

54% |

123586 |

32.3 |

23234.4 |

86.54 |

5.3 |

20107.0 |

|||

|

56% |

131313 |

35.3 |

25380.0 |

86.74 |

5.2 |

22014.6 |

|||

|

58% |

138994 |

38.3 |

27576.0 |

86.89 |

5.0 |

23960.8 |

|||

|

60% |

146597 |

41.4 |

29815.2 |

87.01 |

4.9 |

25942.2 |

|||

|

62% |

154091 |

44.6 |

32097.6 |

87.08 |

4.8 |

27950.6 |

|||

|

64% |

161446 |

47.8 |

34416.0 |

87.13 |

4.7 |

29986.7 |

|||

|

66% |

168629 |

51.0 |

36748.8 |

87.14 |

4.6 |

32022.9 |

|||

|

68% |

175608 |

54.3 |

39110.4 |

87.11 |

4.5 |

34069.1 |

|||

|

70% |

182351 |

57.6 |

41479.2 |

87.05 |

4.4 |

36107.6 |

|||

|

72% |

188827 |

60.9 |

43848.0 |

86.95 |

4.3 |

38125.8 |

|||

|

76% |

200845 |

67.4 |

48556.8 |

86.65 |

4.1 |

42074.5 |

|||

|

80% |

211414 |

73.8 |

53100.0 |

86.25 |

4.0 |

45798.8 |

|||

|

85% |

222218 |

80.9 |

58248.0 |

85.69 |

3.8 |

49912.7 |

|||

|

100% |

234190 |

89.6 |

64533.6 |

84.97 |

3.6 |

54834.2 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power Input(W) |

Efficiency(%) |

Efficiency(g/W) |

Power Output(W) |

Temperature(℃) |

|---|---|---|---|---|---|---|---|---|---|

|

780V |

MSC 64x23-P |

38% |

63322 |

11.6 |

9024.6 |

81.50 |

7.0 |

7355.0 |

/ |

|

40% |

70468 |

13.4 |

10467.6 |

82.50 |

6.7 |

8635.8 |

|||

|

42% |

77776 |

15.4 |

12019.8 |

83.32 |

6.5 |

10014.9 |

|||

|

44% |

85222 |

17.5 |

13681.2 |

84.00 |

6.2 |

11492.2 |

|||

|

46% |

92781 |

19.8 |

15436.2 |

84.56 |

6.0 |

13052.9 |

|||

|

48% |

100426 |

22.2 |

17292.6 |

85.03 |

5.8 |

14703.9 |

|||

|

50% |

108132 |

24.7 |

19227.0 |

85.43 |

5.6 |

16425.6 |

|||

|

52% |

115873 |

27.2 |

21231.6 |

85.76 |

5.5 |

18208.2 |

|||

|

54% |

123621 |

29.9 |

23306.4 |

86.03 |

5.3 |

20050.5 |

|||

|

56% |

131349 |

32.6 |

25451.4 |

86.25 |

5.2 |

21951.8 |

|||

|

58% |

139029 |

35.4 |

27643.2 |

86.43 |

5.0 |

23892.0 |

|||

|

60% |

146630 |

38.3 |

29889.6 |

86.57 |

4.9 |

25875.4 |

|||

|

62% |

154125 |

41.3 |

32175.0 |

86.66 |

4.8 |

27882.9 |

|||

|

64% |

161481 |

44.2 |

34499.4 |

86.71 |

4.7 |

29914.4 |

|||

|

66% |

168669 |

47.3 |

36855.0 |

86.72 |

4.6 |

31960.7 |

|||

|

68% |

175656 |

50.3 |

39241.8 |

86.69 |

4.5 |

34018.7 |

|||

|

70% |

182409 |

53.4 |

41636.4 |

86.62 |

4.4 |

36065.4 |

|||

|

72% |

188895 |

56.5 |

44046.6 |

86.53 |

4.3 |

38113.5 |

|||

|

76% |

200925 |

62.6 |

48804.6 |

86.24 |

4.1 |

42089.1 |

|||

|

80% |

211457 |

68.4 |

53344.2 |

85.89 |

4.0 |

45817.3 |

|||

|

85% |

222052 |

74.8 |

58328.4 |

85.42 |

3.8 |

49824.1 |

|||

|

100% |

232212 |

81.5 |

63546.6 |

84.87 |

3.7 |

53932.0 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.